- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Weight (KG):

-

50000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGLI

Grain Dryer

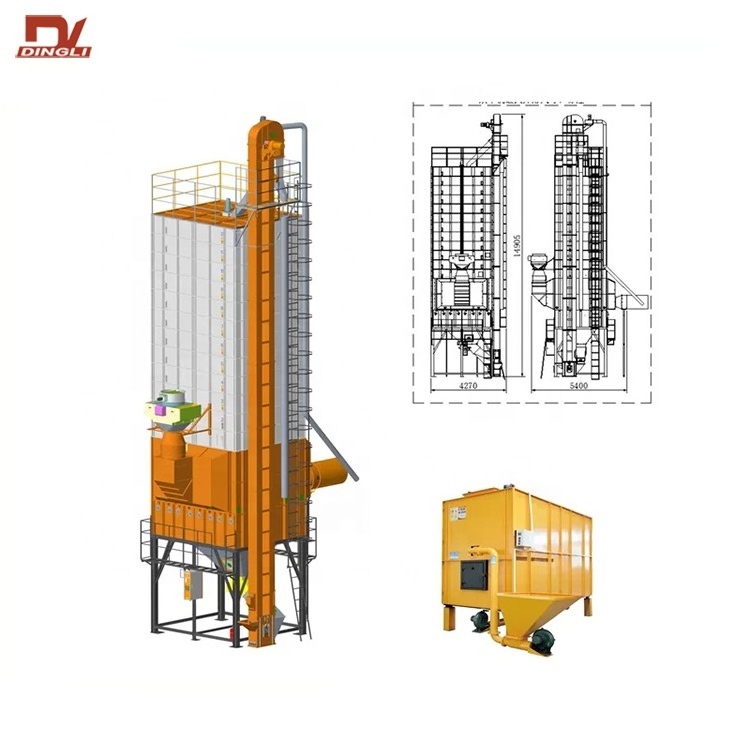

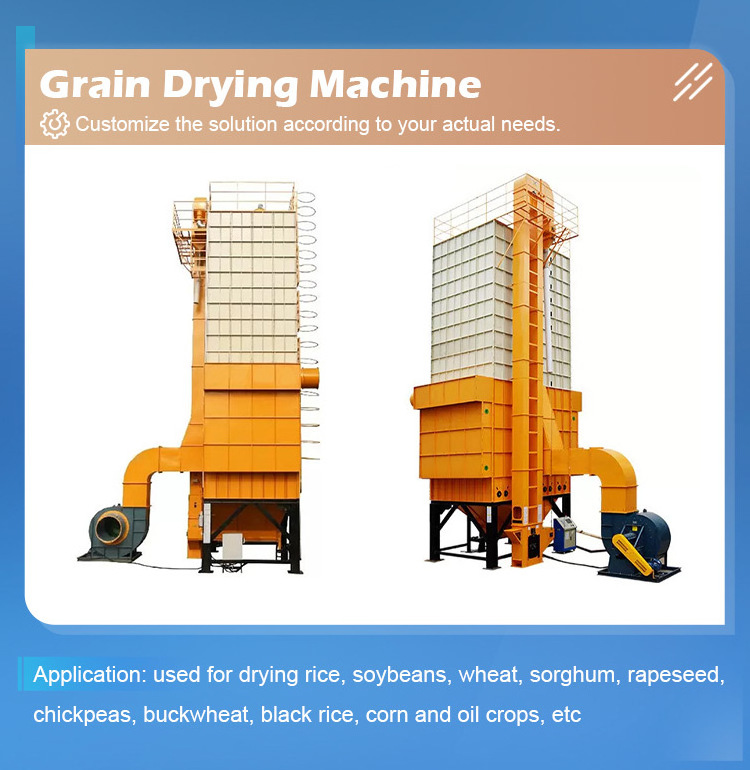

Paddy Rice Grain Dryer Machine with high capacity increase the mesh, raise the utilization ratio of plate and increase hot air through the area and speed up the drying, improve drying uniformity; Remove the upper screw conveyor structure,reduce grain damage rate and emptying time, improve the rate of whole grain.

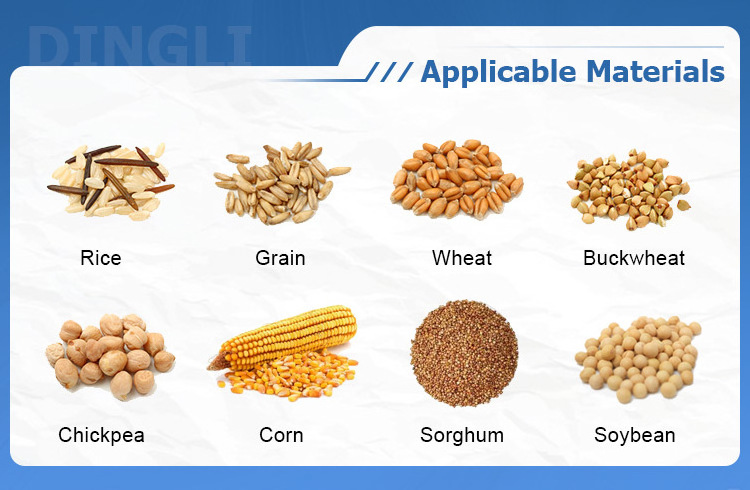

This vertical dryer is suitable for drying rice, wheat, corn, soybean and other grains.

|

Model

|

Capacity (t/d)

|

Reduce moisture range(%)

|

Hot-blast temperature(℃)

|

Most bearing temperature

of grains(℃)

|

Unevenness of drying(%)

|

Dryer Dimension(M)

|

Dryer Height(M)

|

|||||||

|

DLLG100

|

100

|

13~15

|

Corn,Soybean < 120;Rice< 65

|

55

|

< 0.2

|

4×3

|

6~10

|

|||||||

|

DLLG150

|

150

|

|

|

|

|

4×3

|

8~15

|

|||||||

|

DLLG200

|

200

|

|

|

|

|

5×3.2

|

13~17.5

|

|||||||

|

DLLG250

|

250

|

|

|

|

|

5.5×3.2

|

14~18

|

|||||||

|

DLLG300

|

300

|

|

|

|

|

5.5×4

|

14~19

|

|||||||

|

DLLG400

|

400

|

|

|

|

|

5.5×4.5

|

15~20

|

|||||||

|

DLLG500

|

500

|

|

|

|

|

6×6

|

16~22

|

|||||||

|

Heat source:Biomass, coal, natural gas, fuel oil, electric heat pump

Loading capacity:According to the environment, conditions, moisture reduction and configuration |

|

|

|

|

|

|

|

|||||||

WORKING PRINCIPLE

Rice dryer is ideal drying equipment to dry corn grain. Rice is put into the top by bucket elevator, through the feeding device, to ensure that the equipment during operation is always in full loading condition. Induced draft fans introduce cleaning hot air into the inside of the tower body, through the drying section so that rice can be mixed with cleaning hot air, and a majority of dried air can be recycled. Water vapor is discharged from the exhaust system.

Hot Searches