- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIAYUAN

-

Dimension(L*W*H):

-

1800*1000*1500mm

-

Weight:

-

800kg

-

Product name:

-

samll capacity water bottling machine

-

Function:

-

Bottle Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Filling material:

-

minieral water, pure water

-

Capacity:

-

1000-2000bph

-

Material:

-

SUS304/316

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2020

Quick Details

-

Machinery Capacity:

-

2000BPH, 1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIAYUAN

-

Dimension(L*W*H):

-

1800*1000*1500mm

-

Weight:

-

800kg

-

Product name:

-

samll capacity water bottling machine

-

Function:

-

Bottle Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Filling material:

-

minieral water, pure water

-

Capacity:

-

1000-2000bph

-

Material:

-

SUS304/316

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2020

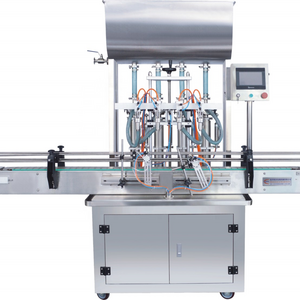

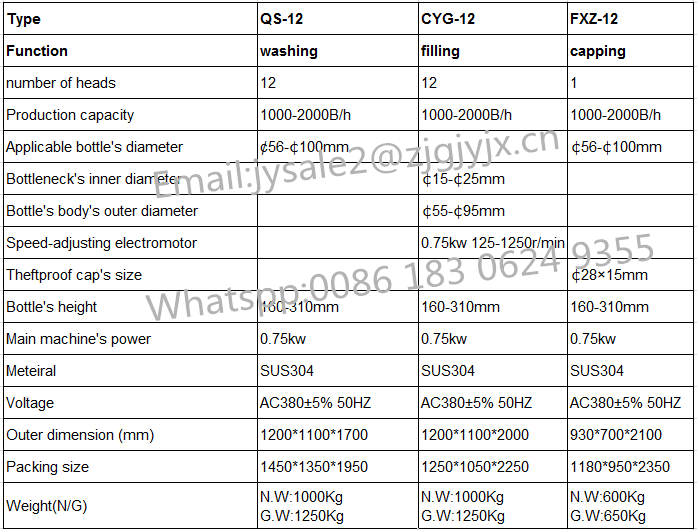

Split liner water washing filling capping machine,

it's capacity is 2000bph, it's suitable for small scale production or new start business.

the overall look

Bottle Rinser:

The split machine is designed to effectively internally rinse up to 2,000 small bottles per hour/50 bottles per minute. It's ideal for rinsing bottles ranging in size from 12 oz (300ml) up to 2 liters. The change over from one size bottle to another couldn't be easier. It takes literally minutes and no tools are required nor are there any special molds or adapters required for the change overs. The stainless steel construction ensures years of a long and durable life for the system and since there are a minimum of moving parts maintenance to keep the system operating and maximum efficiency is a snap.

Bottle Filler & Automatic Conveyor System:

The CYG12-12-1 is designed to automatically fill up to 2,000 bottles per hour and provides maximum versatility to keep pace with the demands of your operation. The CYG12-12-1 is designed and built to operate multiple shifts with a minimum of the maintenance and does not require highly skilled operators. The state-of-the-art design and components offer maximum performance, reliability and versatility to fill from 330ml up to 2L bottle. The main 24foot conveyor automatically moves the pre-labeled bottle to the Rinser , then on to the Filler, the further down the track for manual cap application and for final cap.

Bottle Capper:

The CYG12-12-1 is also one of the most unique capping systems available. To begin with, the filled bottles first enter the build-in Bottles Spacing Mechanism. The bottles spacer allows for precise and constant bottle spacing while entering the Cap Applier. This correct spaceing ensures that your caps are applied evenly and consistently with the most accurate alignment possible. In preparation for cap application, caps are first moved, from the shipping carton, into the Cap Hopper. The Cap Hopper is located at approximately 48" above floor level for easy loading. After the caps have been moved into the hopper, they are elevated to the upper level "Cap Disbursement Chute".

electrical parts