- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Underground pipe laying

-

Color:

-

Customised

-

Engine Type:

-

Cummins 179kW

-

Certification:

-

ISO9001

-

Weight:

-

15 ton

-

Speed:

-

Slow, high

-

Mud pump:

-

500L/min

-

Usage:

-

Underground cable laying

-

Drill rod:

-

OD89*4500

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Juli

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Underground pipe laying

-

Color:

-

Customised

-

Engine Type:

-

Cummins 179kW

-

Certification:

-

ISO9001

-

Weight:

-

15 ton

-

Speed:

-

Slow, high

-

Mud pump:

-

500L/min

-

Usage:

-

Underground cable laying

-

Drill rod:

-

OD89*4500

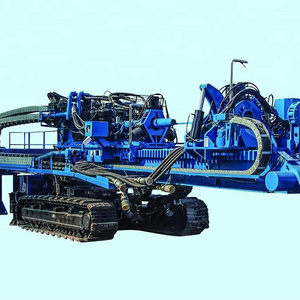

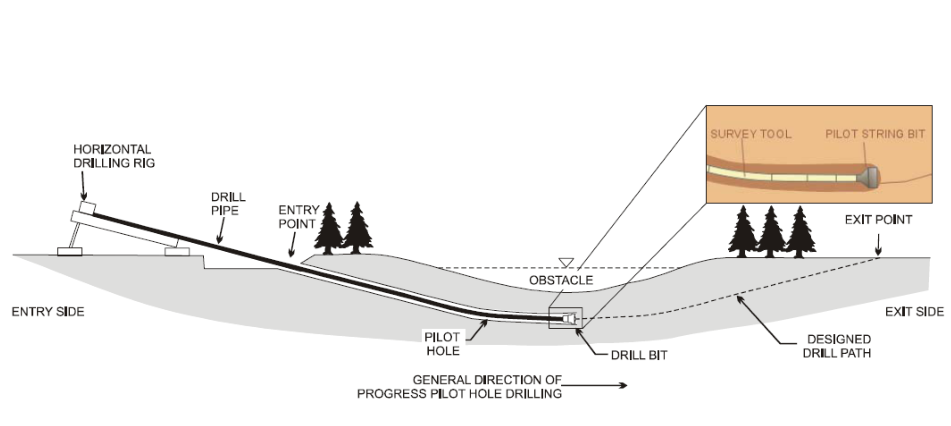

JL-45 ton Horizontal Directional Driller is a new underground piping construction machinery which is based on the advanced theory of “Trenchless Technology”. With fully hydraulic and power-drive technology, it achieves drilling, rotating, back-broaching, back-towing, and travelling. It is widely used for pipeline construction and maintenance for water supply, coal gas, electric power, telecommunication, natural gas, and petroleum in railways, roads, buildings, rivers, and other construction-limited areas, such as cultural protection areas, downtown areas, crops and vegetation conservation areas.

Rubber crawler Gear and rack

F2, F5, GL350, GL600 tracking device system

| JL-45 ton horizontal directional drilling machine | |

| Specifications | |

| Engine Brand | Cummins6CTA8.3-C240 (179kW) |

| Weight of machine | 15000kg |

| Overall Dimension (L×W×H) | 6900x2250x2500 |

| System voltage | 24V |

| Operational | |

| Pullback(max) | 450kN |

| Thrust(max) | 450kN |

| Spindle torque(max) | 18000Nm |

| Spindle speed | 0-65-100r.p.m |

| Incidence angle | 8-20° |

| Ground drive speed | 0-1.5km/h |

| Grade ability | 25° |

| Drilling parts | |

| Diameter of bit | 89mm |

| Length of drill pipe | 4500mm |

| Specification of backreamer | Ø300, Ø400, Ø500, Ø600, Ø700 |

| On-board fluid system | |

| Max pressure | 8Mpa |

| Max flow rate | 500L/min |

Engine system Cummins engine: It can meet complicated jobsites construction demand. The engine also has high reliability and low energy consumption. |

Mud pump Adopt ‘Tongfang’ mud pump which has 4 flow rates and 4 level pressures. So it can meet different diameter holes drill and pullback. The hydraulic motor drives the system, offering high pressure and stable performance.

|

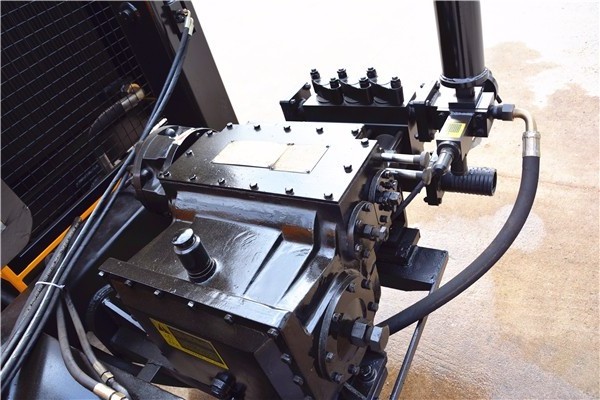

Push and pull device Adopt motor and chain structure, rack and pinion structure, offering stable move, huge push force, convenient maintenance and reliability. |

Travel system Use the same system as excavator system’s support wheel, guide wheel, track idler, driving ring and spring. Rubber crawler or steel crawler with rubber palte has no damage to the road. Huge torque motor ensures strong grade ability.

|

|

Clamping device The open-loop clamping structure is adopted, making the operation intuitive, convenient and reliable. |

Power head Adopt ‘Tilorms’ large torque cycloid motors, power takeoff is much stronger. The two-speed rotation is controlled in the electro-hydraulic way and it is easy to operate.

|

- Engineers available to service machinery overseas

- Offices in India, Indonesia

- Spare part will be sent immediately

- 24 hours online technical support

- Total logistics information tracking report