- Product Details

- {{item.text}}

Quick Details

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Tajikistan, Canada, Saudi Arabia

Quick Details

-

Place of Origin:

-

China

-

Application:

-

Brazing & welding

-

After-sales Service Provided:

-

Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Tajikistan, Canada, Saudi Arabia

Product Application

Application field: high-precision heat treatment process(hardening, tempering, annealing, hardening &tempering),hot forging,preheating, welding,brazing,casting and so on.

Brazing&Welding machine models:

|

Model

|

Power(KW)

|

Frenquency(Khz)

|

|

High frenquency

|

7-30

|

50-200

|

|

Ultrasonic Frenquency

|

30-160

|

10-30

|

|

Middle Frequency

|

100-800

|

0.5-10Khz

|

Main Features

1, CNC quenching machine overview: This machine is a vertical CNC quenching machine, the workpiece is fixed in the bottom top and can be rotated, transformer-inductor

(Load platform) move up and down.

The machine can complete the work of fixed point timing integral quenching, continuous scanning quenching and segmented positioning scanning quenching

Can.

2, CNC quenching machine application scope: suitable for all kinds of shaft and disk workpiece surface induction quenching, widely used in cars, tractors, spinning

Weaving, military engineering machinery and other industries in the field of induction heat treatment.

It is suitable for quenching single and batch workpieces with reasonable structure, complete functions and operation

Easy to use.

3, numerical control quenching machine technical characteristics:

3.1 Transmission system of worktable and load platform is driven by servo motor, driven by ball screw pair, and driven by transmission mechanism to rotate the ball screw.

Realize the lifting movement of the platform, high guiding accuracy, accurate positioning, moving speed can be set by the numerical control system according to the process requirements.

The workpiece speed

Stepless speed regulation, transformer - inductor feed speed stepless speed regulation, and can be very convenient to realize the workpiece fast feed and return.

heated

The workpiece is heated while rotating while feeding, so as to realize the uniform heating temperature of the workpiece and ensure the stability of quenching quality.

3.2 The mechanical structure of the machine adopts reasonable and advanced design, the main and auxiliary guide rails are linear bearings, high accuracy, small friction, long life, surface

Chromium-plated, corrosion resistant.

Transmission parts selection of ball screw, high speed, wear resistance, excellent performance, reliable quality.

3.3 The spindle speed is controlled by frequency converter and adjustable without pole.

3.4 This machine tool has automatic and manual functions.

Set manual gear, automatic gear, two gear exchange.

3.5 The CNC system of the machine tool has comprehensive functions, stable and reliable quality and low failure rate.

The quenching process is automatically controlled by numerical control system

System.

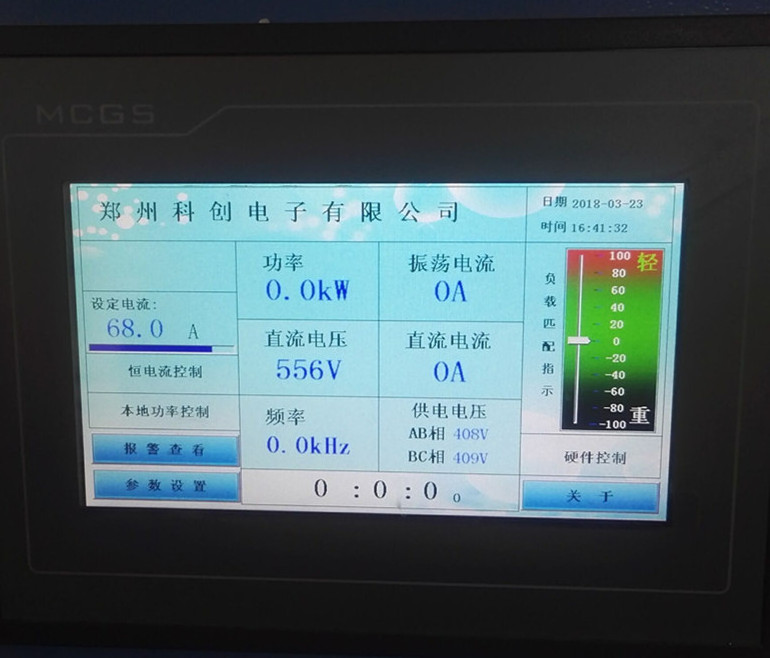

LCD display, Chinese interface, operation panel provides keys for all CNC operation, programming, and machine control actions.

Through the numerical control

The keyboard can select, delete, modify and call the process program, and the system can store the quenching process program of 63 parts.

System Settings

Loss of power braking protection, offside protection.

It has the function of alarm diagnosis information, and has high safety and reliability.

3.6 The machine tool is set with three-color light, indicating green for working process, yellow for waiting process and red for abnormal condition.

3.7 An emergency stop button is set on the operation panel of the numerical control system to realize emergency shutdown

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

|

Size

|

main boby:2100x900x1940mm

|

|

|

Weight

|

1.6T

|

|

|

Packaging Details

|

The normal package is plywood box(Size: L*W*H).

If need,we will pack it according to customers' special request.

|

|

Dsp Intelligent Digital Induction Heating Equipment

91.8% Response Rate

Set of Intelligent induction heating equipment with robot arm

91.8% Response Rate

Saw annelling equipment

91.8% Response Rate