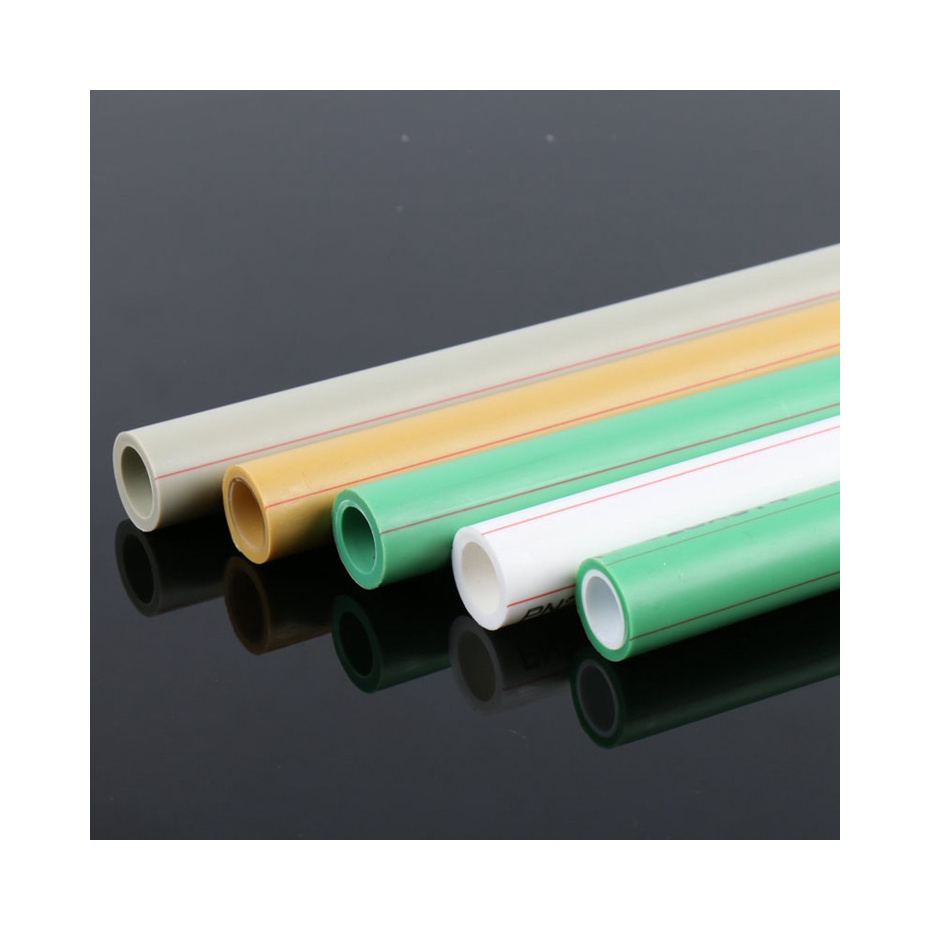

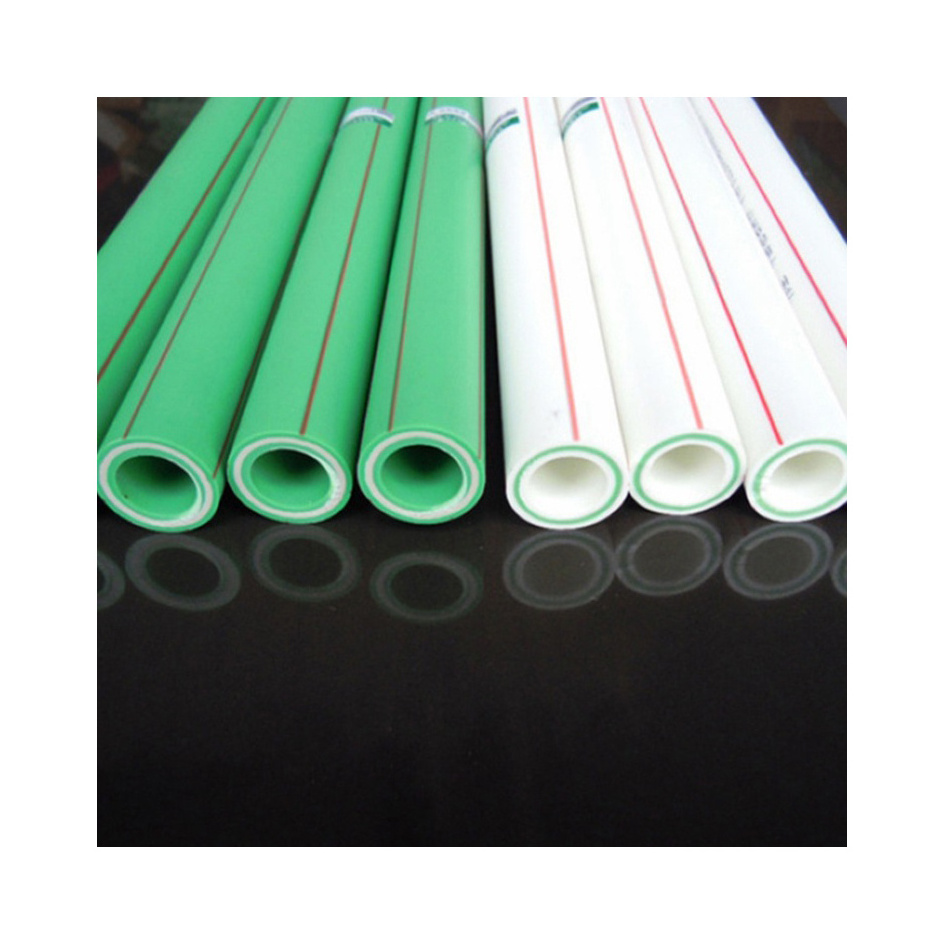

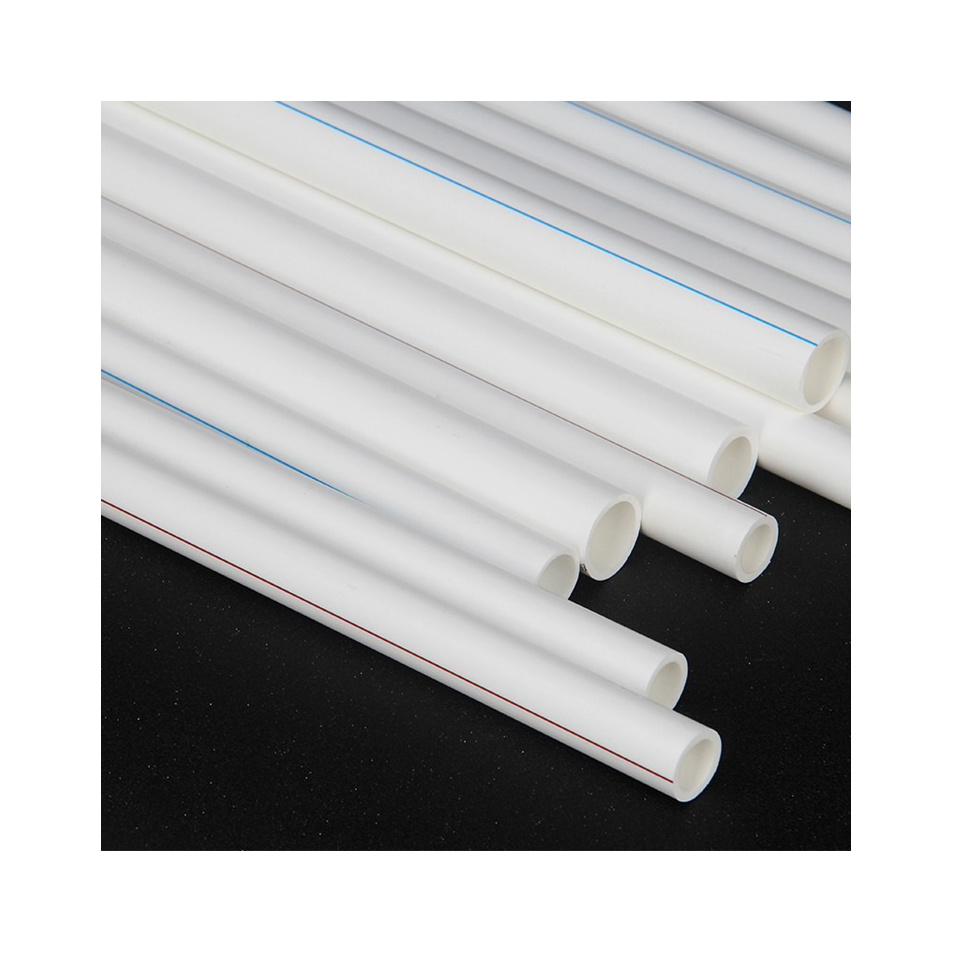

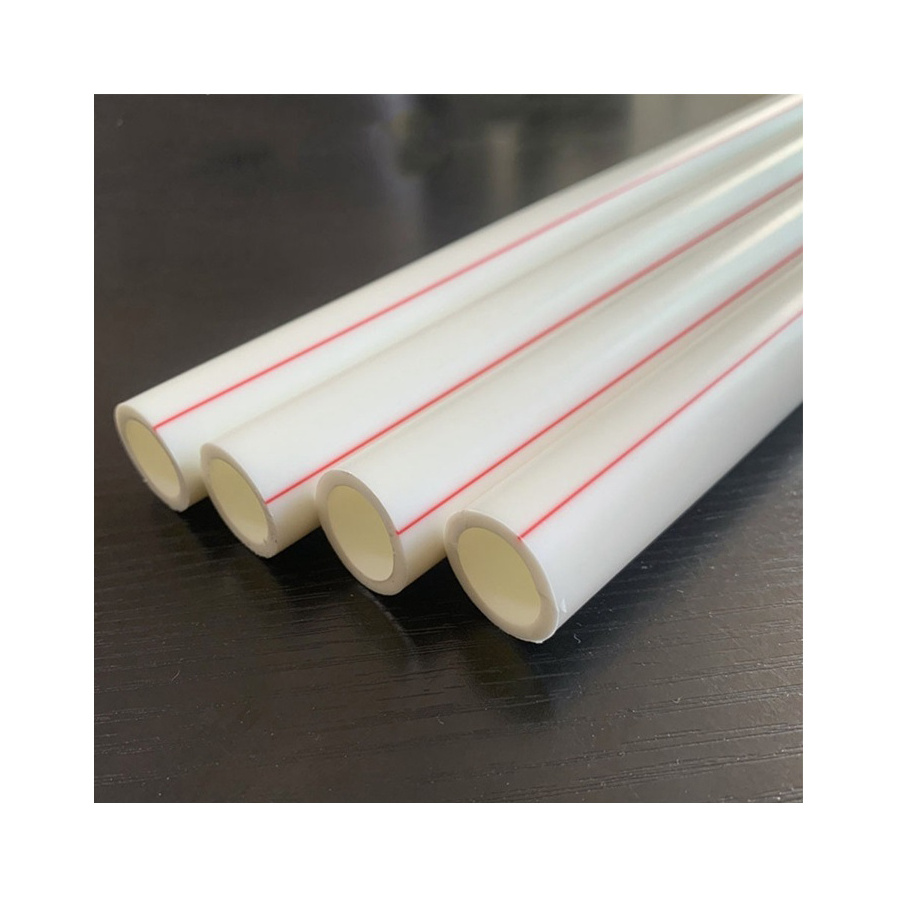

Our raw materials are imported from South Korea, with special temperature and pressure resistance and special quality. The PPR water pipe has a long service life, is corrosion-resistant and does not scale, and can be durable for at least 70 years under normal temperature and pressure. The PPR water pipes are made of brand new materials, which will not produce pungent odors during welding, and will only produce carbon dioxide and water after full combustion, so you can use drinking water with confidence.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

001

-

Length:

-

2meters or your request, Customized Length

-

Thickness:

-

1mm-5mm or up to your request, 2mm~60mm

-

Standard:

-

ISO

-

Color:

-

Customized

-

Working pressure:

-

0.2mpa-2.5mpa

-

MOQ:

-

1X20 GP

-

Product name:

-

PPR PIPE

-

Sample:

-

Sample Availble

-

Usage:

-

Hot & Cool Water

-

OEM:

-

Support OEM

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YiFang

-

Model Number:

-

001

-

Length:

-

2meters or your request, Customized Length

-

Thickness:

-

1mm-5mm or up to your request, 2mm~60mm

-

Standard:

-

ISO

-

Color:

-

Customized

-

Working pressure:

-

0.2mpa-2.5mpa

-

MOQ:

-

1X20 GP

-

Product name:

-

PPR PIPE

-

Sample:

-

Sample Availble

-

Usage:

-

Hot & Cool Water

-

OEM:

-

Support OEM

Products Description

|

Title

|

YiFang Factory Germany Standard Free Sample Oem Color Plastic Polypropylene Ppr Pipe

|

|

PRODUCT NAME

|

PPR hot and cold water pipes

|

|

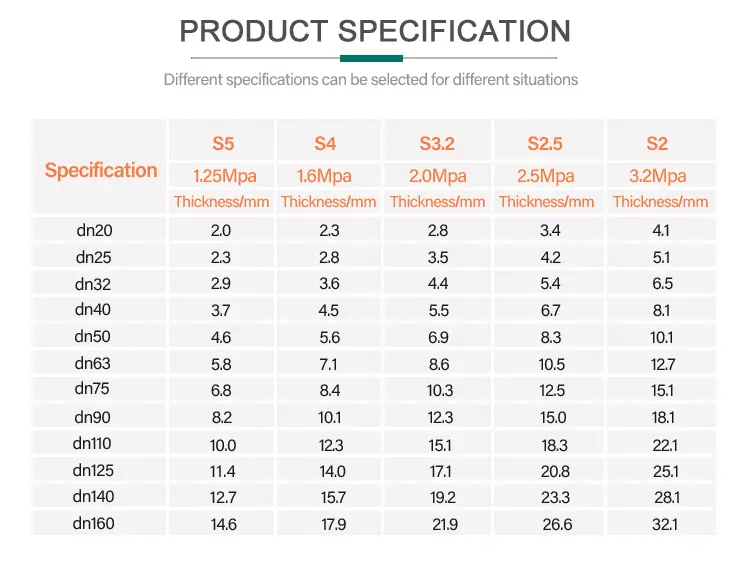

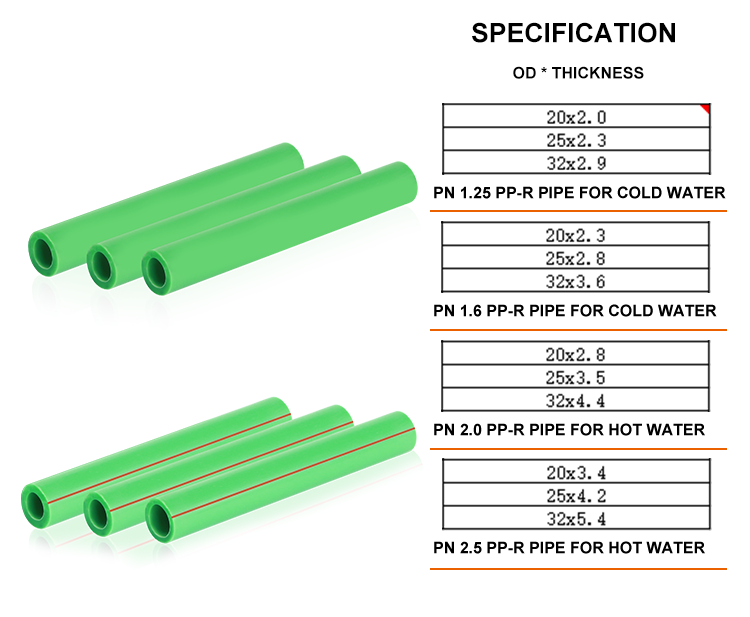

SPECIFICATIONS

|

20-110mm

|

|

MATERIAL

|

Korea Hyosung raw materials

|

|

APPLICATION FIELD

|

Home lmprovement and Engineering

|

|

PRODUCT FEATURES

|

Pressure resistance, corrosion resistance

|

PPR PIPE

Research & Development

1.Material research

2. Material analysis here.

3. Material preparation

4. Material strength test

5. Material tensile testing

6. Material pressure detection

Manufacturing Technique

Capacity

Detection

1. Ring stiffness/ring compression bending/initial ring stiffness

In this test a pipe of specified length is compressed between two flat discs. The length of pipe taken depends on the nominal diameter of the pipe.

2. Determination of creep properties of thermoplastic pipes

During the test, a constant radial force is applied to the tubular component. Deform the circular cross-section of the pipe by 1.5%.

3. Tensile properties

To characterize this property, test specimens were taken from the pipe wall along the length of the pipe.

4. Strain hardening resistance to slow crack growth

The specimen shape used for this test method is a small dumbbell-shaped specimen with wider ends.

5. Testing plastics for MFR and MVR

The melt index test is a test method used to determine the flow properties of thermoplastic materials.

6. Vicat softening temperature

This test involves the characterization of the thermal properties of thermoplastic pipe materials.

Hot Searches