|

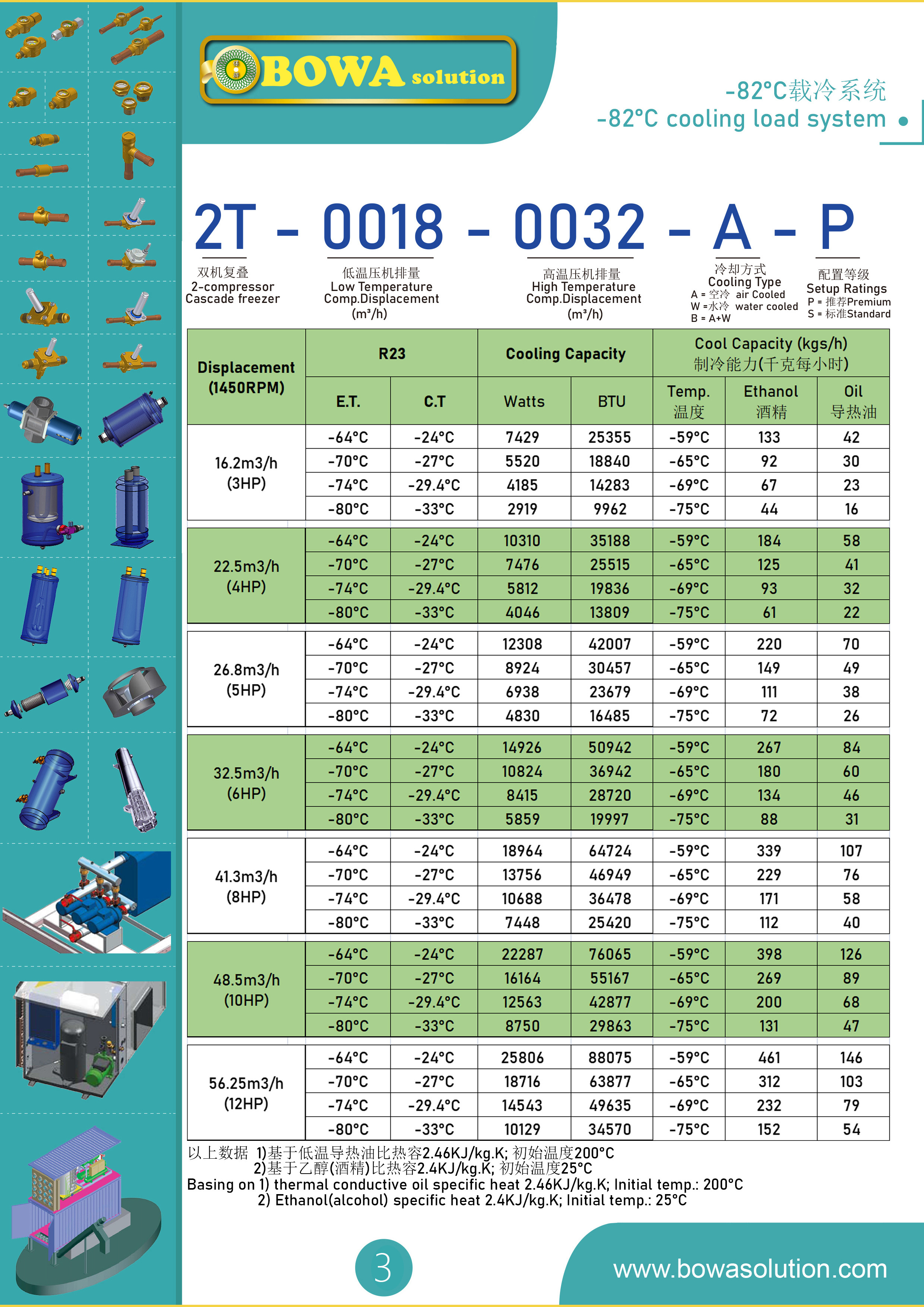

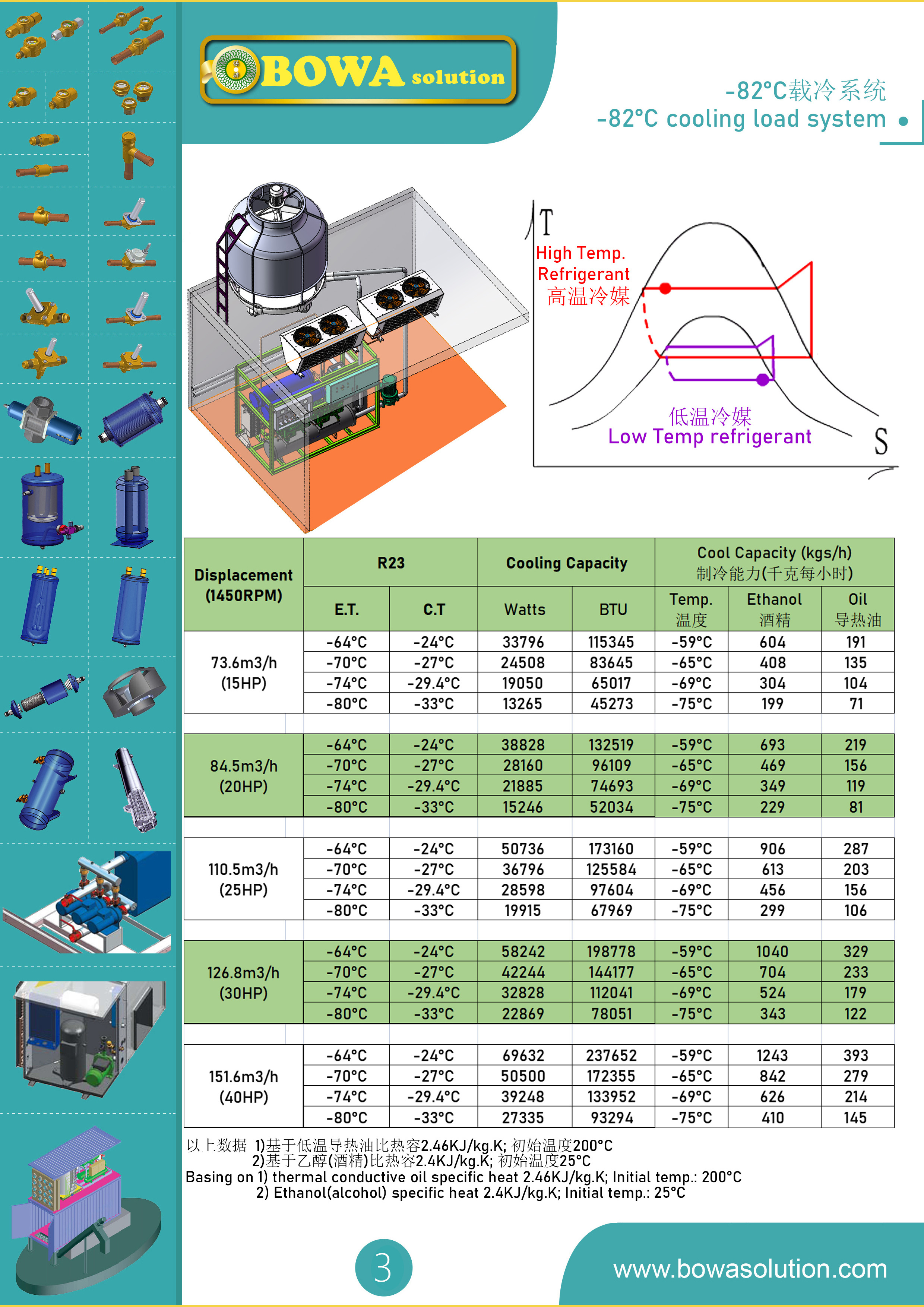

Basing on ethanol specific heat 2.46KJ/KG.'C, inlet temp. 200'C

|

|

|

|

|

No

|

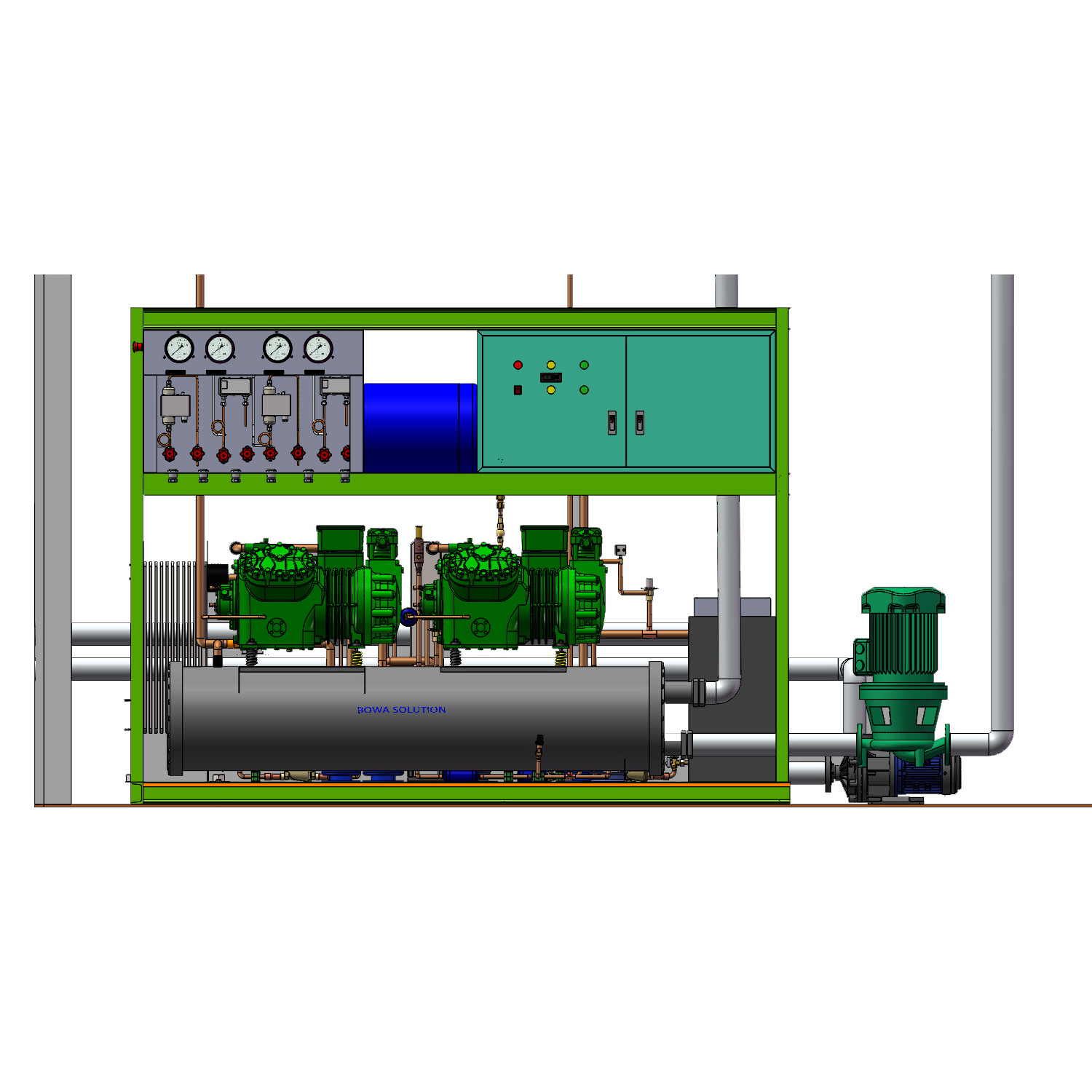

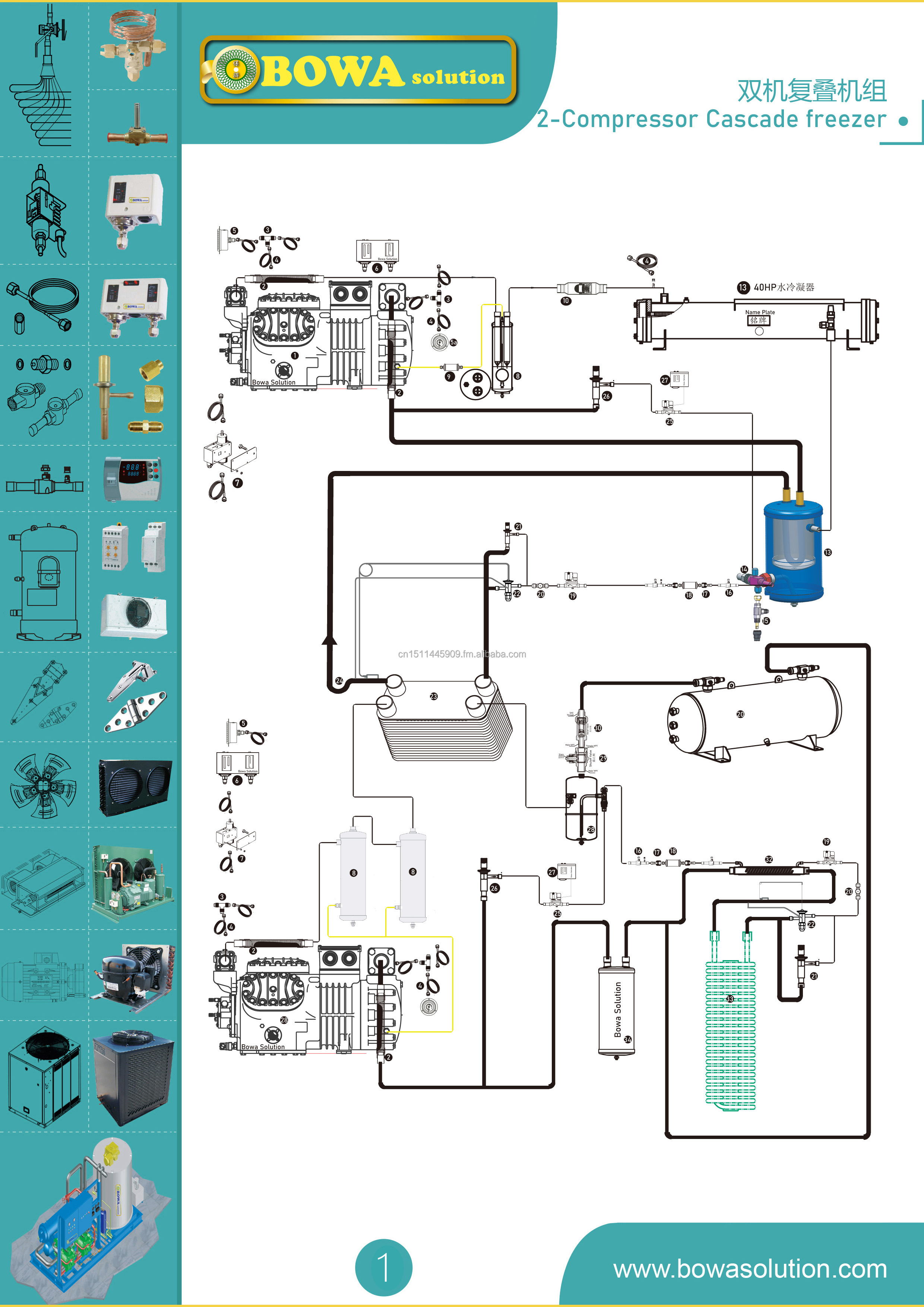

Main parts

|

Key Parameters

|

|

|

|

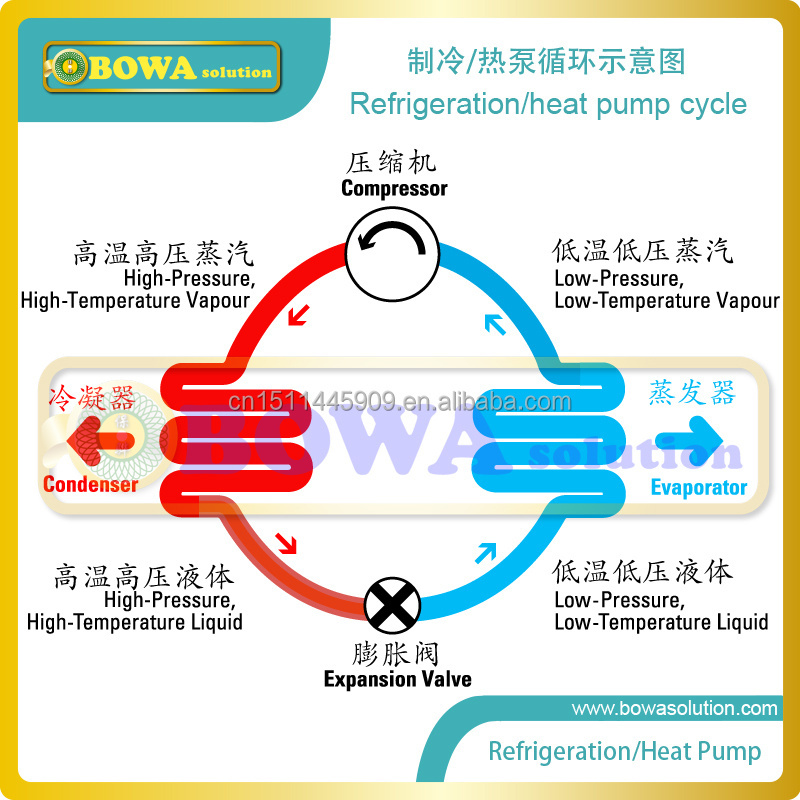

R23 compressor

|

16.2m3/h Dis. at 50Hz

|

|

|

|

Suction & Discharge tubing protector

|

7/8" & 5/8" Vibration Absorber (Stainless steel & copper)

|

|

|

|

Pre-cooler

|

PHE

|

Cooling from R410a stage

|

|

|

Oil Temperature control

|

Crankcase heater

|

If need

|

|

|

Oil Separator

|

Helical

|

with 5/8" check valve

|

|

|

Oil Level control

|

NO

|

|

|

|

Oil Cleaning

|

Oil Filter

|

3/8"

|

|

|

Oil status indicator

|

Sight Glass

|

3/8"

|

|

|

Compressor motor temperature protector

|

Liquid injection

|

switch on/off by discharge temp.

|

|

|

motor protector

|

phase, voltage, current

|

|

|

|

motor shaft power limit

|

Constant pressure valve

|

When hot gas defrosting

|

|

|

Compressing Ratio control

|

Dual pressure Switch

|

Usually manual at high side

|

|

|

Liquid shock protector

|

Accumulator

|

|

|

2

|

R410a compressor

|

22.5m3/h dis. at 50Hz

|

|

|

|

Suction & Discharge tubing protector

|

7/8" & 5/8" Vibration Absorber

|

|

|

|

Oil Temperature control

|

Crankcase heater

|

If need

|

|

|

Oil Separator

|

Helical

|

with 5/8" check valve

|

|

|

Oil Level control

|

NO

|

|

|

|

Oil Cleaning

|

Oil Filter

|

3/8"

|

|

|

Oil status indicator

|

Sight Glass

|

3/8"

|

|

|

Compressor motor temperature protector

|

Liquid injection

|

switch on/off by discharge temp

|

|

|

motor shaft power limit

|

Constant pressure valve

|

If constant evaporating temp.

|

|

|

motor protector

|

phase, voltage, current

|

|

|

|

Compressing Ratio control

|

Dual pressure Switch

|

Usually manual at high side

|

|

|

Liquid shock protector

|

Liquid shock protector

|

|

|

|

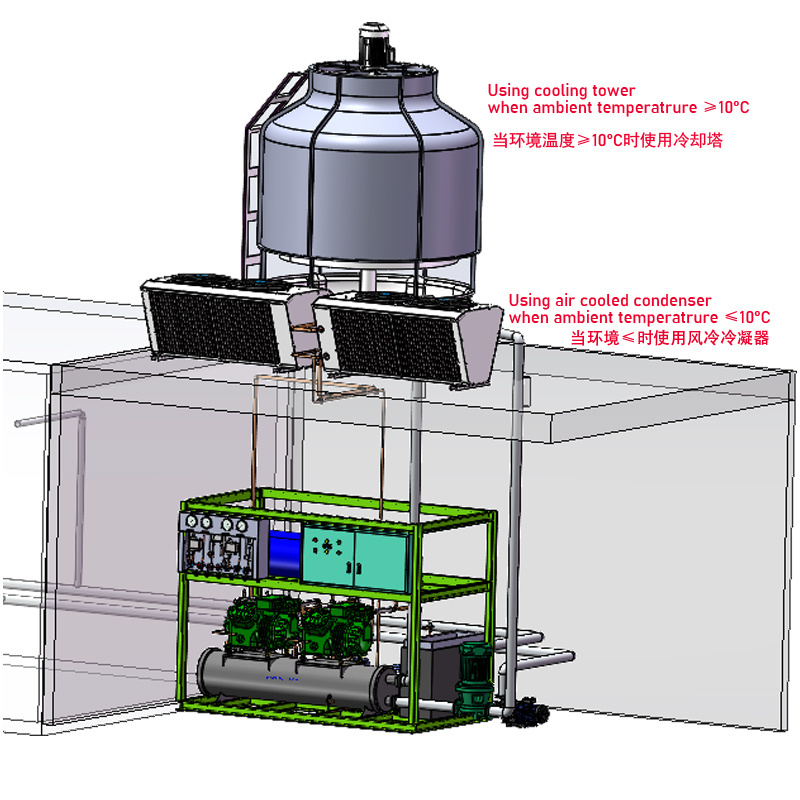

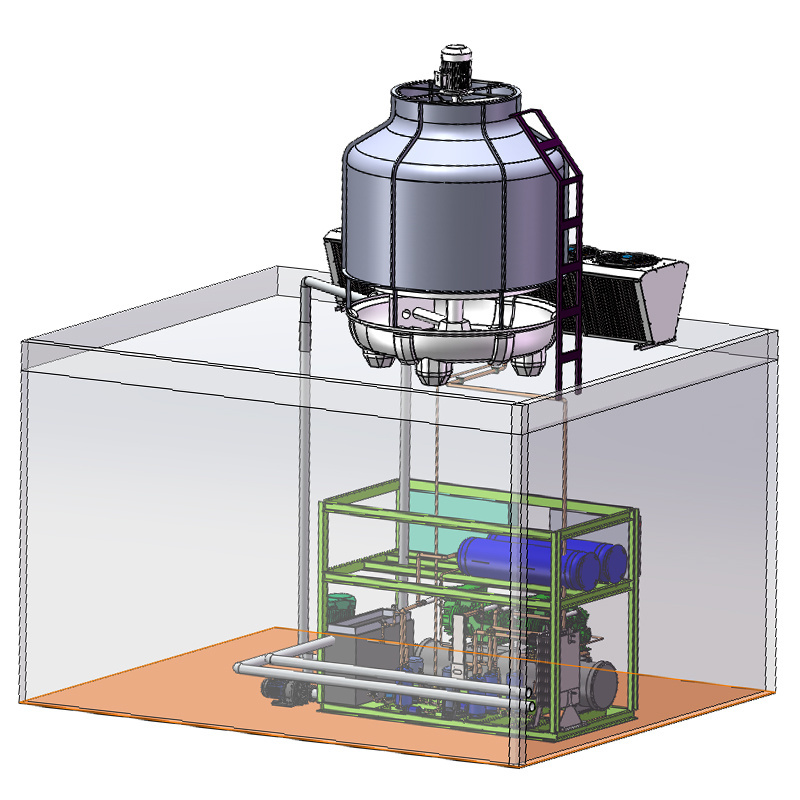

R410a Water cooled condenser

|

Tube & Shell heat exchanger with common copper & Steel

|

|

|

|

Check Valve

|

3/8" Magnetic diaphragm

|

Prevent refrigerant backflow

|

|

|

Pressure operated water valve

|

FBSP water connection & refrigerant 1/4" MSAE flare

|

|

|

|

Flow Switch

|

Anti-freezing protector

|

when water interception

|

|

|

Micro-differential Pressure switch

|

0~70kPa

|

If there exist dirty block rist

|

|

|

R410a air cooled condenser

|

Fin & Tube heat exchanger with V shape

|

|

|

|

Check Valve

|

Magnetic diaphragm

|

Prevent refrigerant backflow

|

|

|

Condenser fan control

|

Pressure Switch

|

Sensor at inlet of condenser

|

|

|

Fan speed control

|

Temperature drived

|

Proportional control

|

|

|

Refrigerant flow direction shift

|

3-way 2-position Valve

|

Horizontal installation

|

|

4

|

R410a Thermostatic expansion valve

|

Main throttle device

|

|

|

|

R410a Solenoid valve for AEV

|

Switch on/off by intermediate temperature setting

|

|

|

|

inter-coolerTemperature Switch

|

-50'C to +100'C

|

Intermediate temp control

|

|

|

R410a Automatic expansion valve

|

Enlarge refrigeration regulating range and anti-freeze

|

|

|

|

R23 Thermostatic expansion valve

|

main throttle device

|

Take-apart body

|

|

|

R23 Solenoid valve for AEV

|

Switch on/off by evaporating temperature setting

|

|

|

|

Evaporating temperature switch

|

-150~+50'C

|

control suction pressure

|

|

|

R23 automatic expansion valve

|

Enlarge refrigeration regulating range and anti-freeze

|

|

|

5

|

Intercooler

|

ASTM 304 Stainless Steel PHE with thread connectors

|

|

|

|

R410a wet steam inlet joint

|

J-4 Rotalock (FSAE->ODF)

|

1/2" ( Bottom port)

|

|

|

R410a dry stam outlet join

|

J-7 Rotalock (FSAE->ODF)

|

7/8" (top port)

|

|

|

R23 hot gas inlet joint

|

J-5 Rotalock (FSAE->ODF)

|

5/8" (top port)

|

|

|

R23 hot liquid outlet joint

|

J-3 Rotalock (FSAE->ODF)

|

3/8" (Bottom port)

|

|

6

|

|

Stainless Steel pipe Coil

|

For plasma

|

|

|

|

Stainless Steel PHE

|

Default

|

|

|

|

Titanium pipe coil

|

For corrosion fluids

|

|

|

|

Copper pipe coil

|

For dirty fluids

|

|

|

|

Air cooler

|

For cold room/air chamber

|

|

|

|

Aluminum pipe

|

Avoid dry consumption

|

|

7

|

Liquid line components

|

Liquid refrigerant reservoir

|

3 Liter or so

|

|

|

|

R23 Relief Valve

|

2.0MPa

|

|

|

|

R23 service valve

|

3/8" NPT ball valve

|

|

|

|

Subcooler & Superheater

|

Liquid 3/8" X 7/8" suction

|

|

|

|

Filter Drier

|

3/8" ODF

|

|

|

|

Shutoff Valves

|

3/8" ODF

|

|

|

|

Solenoid Valve

|

FDF8M-10S

|

|

|

|

Sight Glass

|

3/8" ODF

|

|

8

|

Auxiliary accessories

|

Pressure Gauges

|

one 23 pair & one R410a pair

|

|

|

|

Charging Valves

|

Vaccuum & Charging gas

|

|

|

|

Connection Sets

|

|

|

|

|

Expansion Vessel

|

Safety device

|

|

|

|

TEE

|

Brass & SAE flare

|

|

9

|

Electrical control box

|

System Logic controller

|

|

|

|

|

Current transformers

|

|

|

|

|

Voltage transformers

|

|

|

|

|

Circuit breakers

|

|

|

|

|

Contractors

|

|

|

|

|

Indicator lights

|

|

|

|

|

Turnover Switch

|

|