- Product Details

- {{item.text}}

Quick Details

-

Item:

-

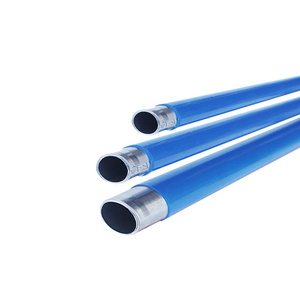

One Stop Service Hot Forged Hardened Stainless Steel Ship Shaft

-

Material:

-

carbon steel,Alloy steel, stainless steel, aluminum, brass,etc

-

Manufacturing Process:

-

Forging, press, plus machining ,heat treatment , assembly

-

Forging Tolerance:

-

+/-0.3~+/-2 mm for forged stainless steel shaft

-

Machining:

-

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

-

Machining Tolearnce:

-

From 0.005mm-0.01mm-0.1mm

-

Surface Treatment:

-

Dacromat Coating, Finish Painting

-

Package of forging:

-

Multi-layer wooden box with big plastic bag inside, or custom

-

Lead Time:

-

45 days for forged stainless steel shaft

-

Service:

-

Supply forged stainless steel shaft

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Matech Industry

-

Model Number:

-

forged stainless steel shaft

-

Item:

-

One Stop Service Hot Forged Hardened Stainless Steel Ship Shaft

-

Material:

-

carbon steel,Alloy steel, stainless steel, aluminum, brass,etc

-

Manufacturing Process:

-

Forging, press, plus machining ,heat treatment , assembly

-

Forging Tolerance:

-

+/-0.3~+/-2 mm for forged stainless steel shaft

-

Machining:

-

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

-

Machining Tolearnce:

-

From 0.005mm-0.01mm-0.1mm

-

Surface Treatment:

-

Dacromat Coating, Finish Painting

-

Package of forging:

-

Multi-layer wooden box with big plastic bag inside, or custom

-

Lead Time:

-

45 days for forged stainless steel shaft

-

Service:

-

Supply forged stainless steel shaft

|

One Stop Service Hot Forged Hardened Stainless Steel Ship Shaft

|

|

|

|

Production Process for cold forged steel forging

|

Forging, press, plus machining ,heat treatment , assembly

|

|

|

According to Drawings Tolerance:

|

+/-0.3~+/-2 mm

|

|

|

Production Applicable Material:

|

Stainless steel: 303, 304, 316L, etc

|

|

|

|

Steel: 4140, Q235, Q345B, 20#, 45#, etc

|

|

|

|

Aluminum: AL 6061-T6, 6063, 7075-T, etc

|

|

|

According to Drawings Size /Dimensions:

|

142 mm- 300mm or according to customer requirement

|

|

|

According to Drawings Weight:

|

Range from 0.1kg-1000kg for forged stainless steel shaft

|

|

|

Applicable Machining Process:

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc.

|

|

|

Machining Tolerance:

|

From 0.005mm-0.01mm-0.1mm

|

|

|

Machined Surface Quality:

|

Ra 0.8-Ra3.2 according to customer requirement

|

|

|

Applicable Heat Treatment:

|

Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

|

|

Applicable Finish Surface Treatment:

|

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting,

|

|

|

MOQ of mass production:

|

For forging parts: 1 Ton

For Machining: 50 Pcs |

|

|

Lead Time:

|

30-40 days from the receipt date of forged stainless steel shaft

|

|

ShangHai Matech Machinery Manumfacture Corporation.ltd

specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market .

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

1.

Your design we help to achieve,as your sincerely partner,

One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow analysis,

Trial & mass production to Final mold assembly & shipment.

2. High skilled and well-trained working team under good management environment.

3. Quick response and support for any inquiries.

4. Over 10 years professional manufacture experience to ensure high quality of your products.

5. Large and strong production capacity to meet your demand.

6. High Quality standard and hygienic environment.

7. Good after sales services

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer's requirements.

Our customers

have become our friends,even what we call family members.

welcome to join us

Our Team

are a big happy family, we not only supplying products to our customers , but also trying to build more values to our customers' business by introducing suitable solution or technology to our customers with compromising parts' function, technologies' advantage, realization feasibility, cost control and quality reliability.

Our Core Value is Sincerity Quality Competence

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.