→cutting and curing→slab palletizing→wallboard application

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

7KW

-

Weight:

-

1000 kg

-

Name:

-

Precast cement board machine

-

Application:

-

Fence Wall ,exterior wall,Partition panelfloor,ceiling,etc

-

Raw material:

-

cement, sand,construction waste

-

Features of finished product:

-

Fire prevention, heat preservation

-

Board length:

-

any length

-

Board width:

-

600mm

-

Board thickness:

-

75mm-200mm

-

Capacity:

-

5 million square meters/day

-

load bearing board:

-

yes or no all ok

Quick Details

-

Production Capacity:

-

1.3-1.7m/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Demeng

-

Voltage:

-

220V/380V

-

Power:

-

7KW

-

Weight:

-

1000 kg

-

Name:

-

Precast cement board machine

-

Application:

-

Fence Wall ,exterior wall,Partition panelfloor,ceiling,etc

-

Raw material:

-

cement, sand,construction waste

-

Features of finished product:

-

Fire prevention, heat preservation

-

Board length:

-

any length

-

Board width:

-

600mm

-

Board thickness:

-

75mm-200mm

-

Capacity:

-

5 million square meters/day

-

load bearing board:

-

yes or no all ok

Product Overview

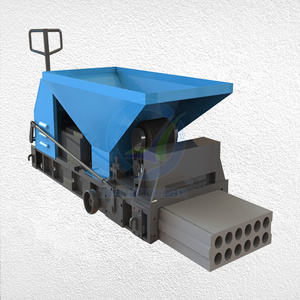

Precast Concrete Lightweight Wall Panel Extruder Board Making Machine Fence Wall Making Machinery for Construction

Flow chart

Raw material processing→material mixing→feeder conveying→extrusion molding

Factory scene

PRODUCT SPECIFICATIONS

|

No.

|

Item

|

Data

|

|

1

|

Board length

|

Any length

|

|

2

|

Board width

|

600mm

|

|

3

|

Board thickness

|

75--200mm

|

|

4

|

Total installed power capacity

|

7KW

|

|

5

|

Production line power voltage

|

220/380V±10%

|

|

6

|

Type

|

Single L, double L, single T, double T, T+L

|

|

7

|

Vibration motor power

|

2.2KW

|

Equipment composition

Raw material blender

Lorry

Tensile machine

wall panel cutter

Wall Panel Forming Machine

1.It can be used for producing interior wall and exterior wall for house building.

2.The final wall panel produced by our machine is more smooth and good apperance

3.One unit of 600mm x 3000mm panel (75mm & 100mm thickness) is equivalent to 112 pieces of bricks ( The panel length can be cut into any length)

4,Total Wall Weight is reduced by approximately 45%.

2.The final wall panel produced by our machine is more smooth and good apperance

3.One unit of 600mm x 3000mm panel (75mm & 100mm thickness) is equivalent to 112 pieces of bricks ( The panel length can be cut into any length)

4,Total Wall Weight is reduced by approximately 45%.

SALES AND SERVICE NETWORK

About Us

SIMILAR PRODUCTS

FAQ

Q:

Why I choose your company?

A:

a) We have made

Gypsum board

machine about 30 years with strong experience and advanced technics.

b) Best Quality & Best Service with Competitive price.

c) 100% inspection Before Shipment

d) We have Professional technical team, supply 24 hours service.

e) One year guarantee and lifetime maintenance.

b) Best Quality & Best Service with Competitive price.

c) 100% inspection Before Shipment

d) We have Professional technical team, supply 24 hours service.

e) One year guarantee and lifetime maintenance.

Hot Searches