- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

290 - 680 mm

-

Ejector Stroke(mm):

-

170 mm

-

Ejector Force(kN):

-

90 kN

-

Theoretical Shot Volume(cm³):

-

1061 cm³

-

Injection Rate (g/s):

-

246 g/s

-

Injection Weight (g):

-

966 g

-

Screw Speed (rpm):

-

0 - 165 rpm

-

Screw diameter (mm):

-

65 mm

-

Screw L/D Ratio:

-

21

-

Distance between Tie Bars:

-

670mm*670mm

-

Weight (KG):

-

13500 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

635 mm

-

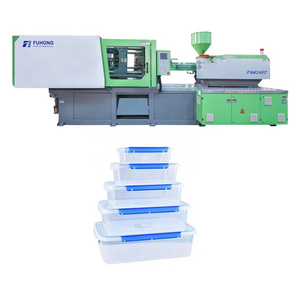

Model Number:

-

FHG360

-

Brand Name:

-

FUHONG

-

Power (kW):

-

37 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Screw Diameter:

-

70MM-80MM

-

Injection pressure:

-

152mpa-199mpa

-

Mould thickness:

-

250mm-780mm

-

Ejector stroke:

-

170mm

-

Heating power:

-

21.4kw

-

Machine dimension(L*W*H):

-

7.2m*2.0m*2.4m

-

Machine weight:

-

13.5ton

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

670mm

-

Distance between Tie Bars(Height)(mm):

-

670mm

-

Plasticizing Capacity(g/s):

-

213

-

Mold Height(mm):

-

290 - 680 mm

-

Ejector Stroke(mm):

-

170 mm

-

Ejector Force(kN):

-

90 kN

-

Theoretical Shot Volume(cm³):

-

1061 cm³

-

Injection Rate (g/s):

-

246 g/s

-

Injection Weight (g):

-

966 g

-

Screw Speed (rpm):

-

0 - 165 rpm

-

Screw diameter (mm):

-

65 mm

-

Screw L/D Ratio:

-

21

-

Distance between Tie Bars:

-

670mm*670mm

-

Weight (KG):

-

13500 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

635 mm

-

Model Number:

-

FHG360

-

Brand Name:

-

FUHONG

-

Power (kW):

-

37 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Screw Diameter:

-

70MM-80MM

-

Injection pressure:

-

152mpa-199mpa

-

Mould thickness:

-

250mm-780mm

-

Ejector stroke:

-

170mm

-

Heating power:

-

21.4kw

-

Machine dimension(L*W*H):

-

7.2m*2.0m*2.4m

-

Machine weight:

-

13.5ton

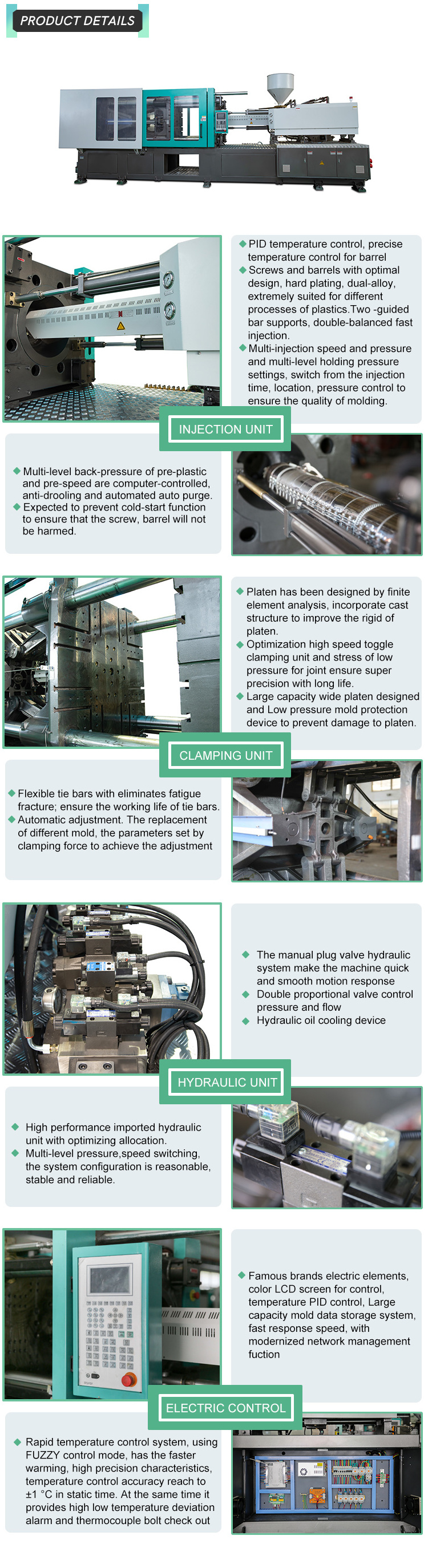

Fuhong injection molding machine Features:

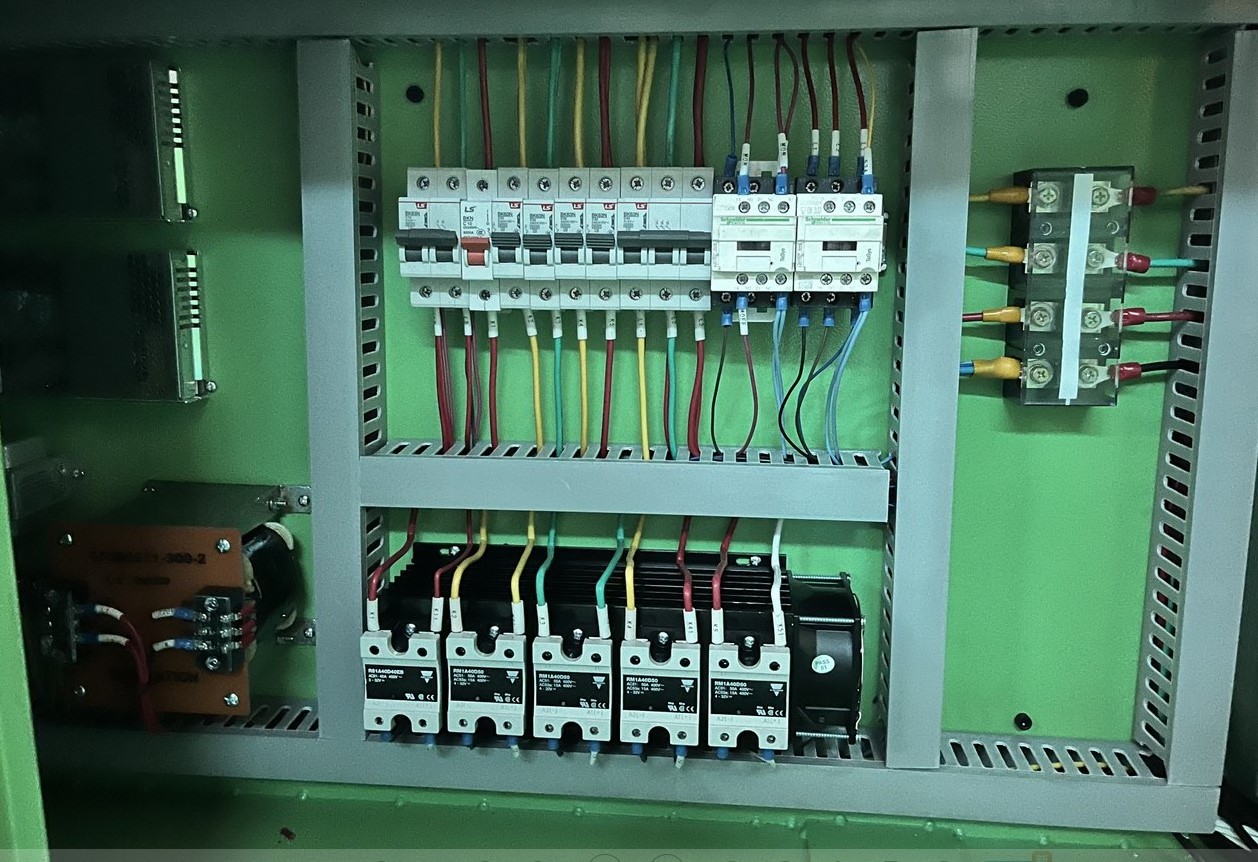

Control system:

*Multiple languages available

*Manual,semi-automatic,full automatic mode

*Can provide EUROMAP robot interface.

*Automatic movement monitoring with alarm and fault diagnosis.

*Function of slope setting can set the start and stop of movements,so as ensure the smooth movement.

Hydraulic system:

*The manual plug valve hydraulic system make the machine having quick and smooth motion response

*double proportional valve control pressure and flow

*Hydraulic oil cooling device

*High-performance imported hydraulic unit with optimizing allocation

*The fuel tank has a big opening hole so can be cleaned easily.

Injection system:

*APID temperature control,precise temperature control of barrel.

*There are three or four size of screw&barrel.with optinal design,respectively,nitride,hard plating,dual-metal,which is suitable for different processes of a variety of plastics,and the choice of product.

*double -guided bar supports,double-balanced rapid injection

*The high-torque hydraulic motors offer a stable plasticizing capacity,high-precision electronic device position detection enable accurate measurement.

Clamping system:

* Security doors fitted ithhydraulic,mechanical and electrical interlocking triple safety device when the safety door is open,the machinecannot clamp.

*Low pressure mold protection device to prevent damage of platen.

*Plywood,frame,the bridge,and the template attached structure,the finite element analysis.

*Hydraulic ejector,adjustable stroke,and top speed of ejector in and out,for multiple actions.

*Flexible tie bar nut eliminates fatigue fracture,assure the working life of the tie bars.

*Automatic adjustment.The replacement of different molds,the parameters set by clamping force to achieve the automatic adjustment.

High-precision electronic detection device,multi-stage contrl of opening stroke,speed and location,location accuracy.

|

ITEM |

UNIT |

FHG360 |

|||

|

Injection Unit |

Screw Diameter |

mm |

60 |

65 |

70 |

|

S crew L/D Ratio |

L /D |

2 2.7 |

2 1 |

19.5 |

|

|

Injection Volume |

cm 3 |

904 |

1061 |

1231 |

|

|

Shot Weight |

g |

823 |

966 |

1120 |

|

|

Injection Speed |

g /s |

225 |

246 |

289 |

|

|

Injection Pressure |

Mpa |

247 |

213 |

182 |

|

|

S crew Speed |

r /min |

0 -165 |

|||

|

Clamping Unit |

Clamping Force |

KN |

3600 |

||

|

Opening Stroke |

mm |

620 |

|||

|

Mould Thickness(Min-Max) |

mm |

2 5 0-70 0 |

|||

|

Space Between Tie-Bars |

mm |

670×670 |

|||

|

Ejector Force |

KN |

90 |

|||

|

Ejector Stroke |

mm |

1 70 |

|||

|

Others |

P ump Pressure |

M pa |

1 6 |

||

|

Motor Power |

KW |

3 7 |

|||

|

Heating Power |

KW |

21.4 |

|||

|

Machine Dimension |

m |

7.20×2.00×2.40 |

|||

|

Machine Weight |

Ton |

1 3.5 |

|||