- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

xingbo

-

Voltage:

-

380v50hz3p

-

Dimension(L*W*H):

-

AS design

-

Weight:

-

6500 kg

-

transmission style:

-

chain or sprocket

-

cutting blade:

-

SKD11

-

shaft material:

-

45#steel

-

roller material:

-

45#steel chrome plated

-

control system:

-

PLC

-

forming speed:

-

8-12m/min

-

name:

-

gutter machine making new continous gutters

-

hydraulic power:

-

5.5kw

-

roller diameter:

-

60mm

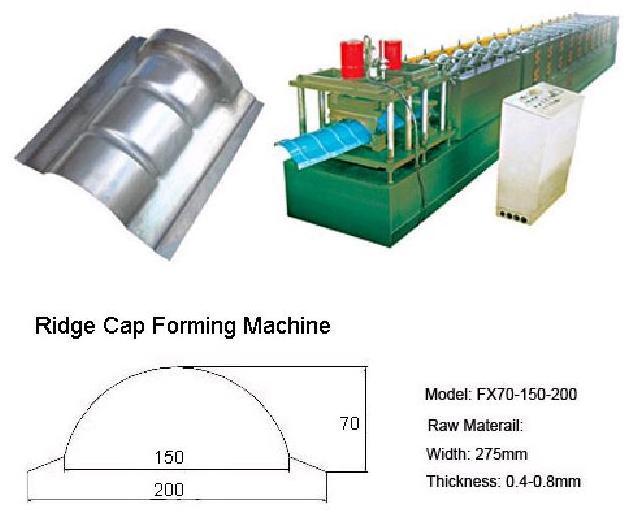

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

25sets/month

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

xingbo

-

Voltage:

-

380v50hz3p

-

Dimension(L*W*H):

-

AS design

-

Weight:

-

6500 kg

-

transmission style:

-

chain or sprocket

-

cutting blade:

-

SKD11

-

shaft material:

-

45#steel

-

roller material:

-

45#steel chrome plated

-

control system:

-

PLC

-

forming speed:

-

8-12m/min

-

name:

-

gutter machine making new continous gutters

-

hydraulic power:

-

5.5kw

-

roller diameter:

-

60mm

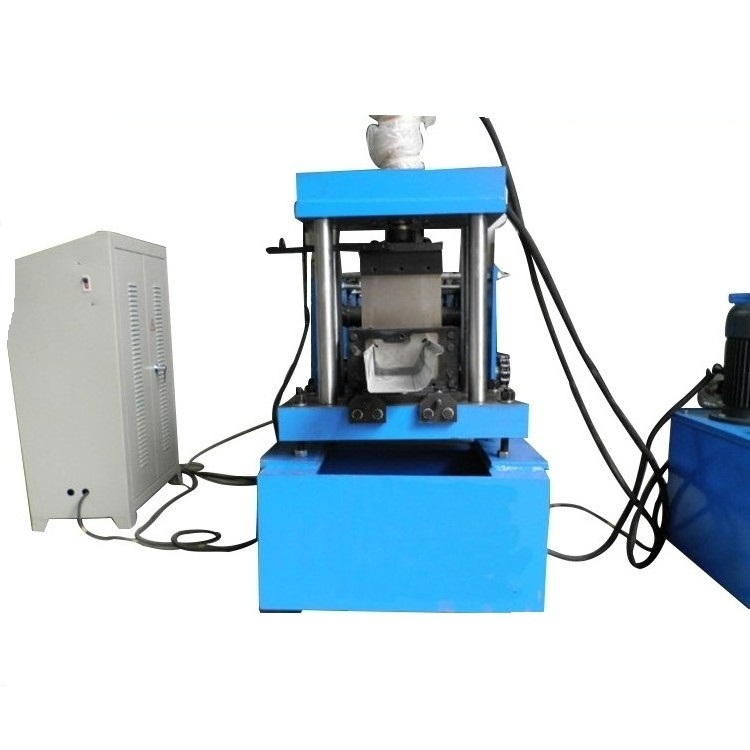

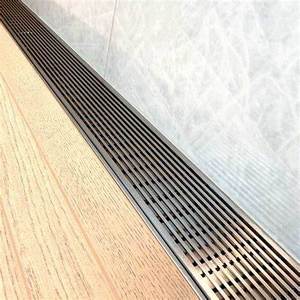

FX gutter machine making new continous gutters

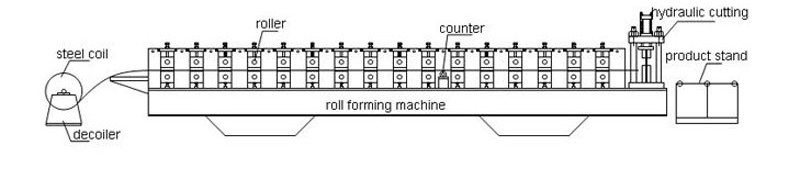

1. Processing flow diagram

Manual decoiler→Feeding material into machine→Roll forming machine→Measure length→Hydraulic cutting→ F inished Products

2. Technical parameters of FX gutter machine making new continous gutters

|

Model number |

FX gutter machine making new continous gutters |

|

Rolled material |

0.3-1.5mm thickness, aluminum sheet, galvanized sheet, colored steel sheet and various steel plates |

|

Effective width |

as customer's require |

|

Feeding width |

as customer's require |

|

Forming steps |

9-18 stations |

|

Roller |

45# forged steel, hard chrome plating within 0.05mm |

|

Diameter of shaft |

70mm |

|

Main motor power |

4 kw |

|

Pump power |

3 kw |

|

Sprocket chain |

1 inch |

|

Drive type |

by chain |

|

Cutting Blade |

Cr12, heat treatment 60-62°C |

|

Frequency Converter |

It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

|

component |

1 set of manual decoiler , 1 set of main roll forming machine , 1 set of computer control cabinet , 1 set of hydraulic System , 1 set of cutting mechanism , 1 set of counter , 1 set of output table |

|

Payment terms |

cash,T/T,L/C. |

Remark: Above parameters are standard, we can design and make some change exactly according to your requirements.

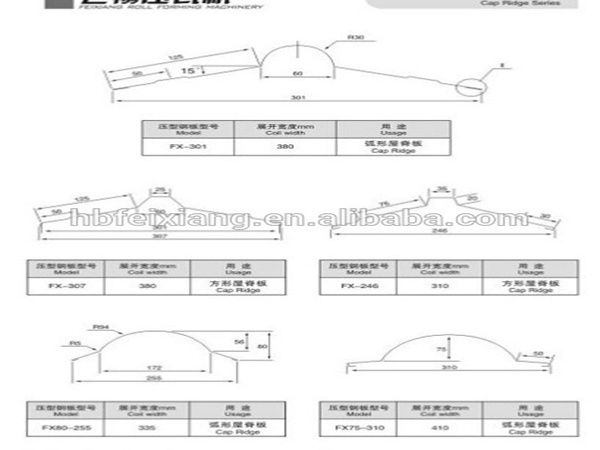

3.Profile and Real photos

4. Details of the machine :

5. After - sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.

B: Training: the buyer should charge of visa, round-trip ticket, food and accommodation

overseas and USD100/person/day for salary.

C: Need one technician.

D: Training time: one week (contains the time of installation and adjustment)