- Product Details

- {{item.text}}

Quick Details

-

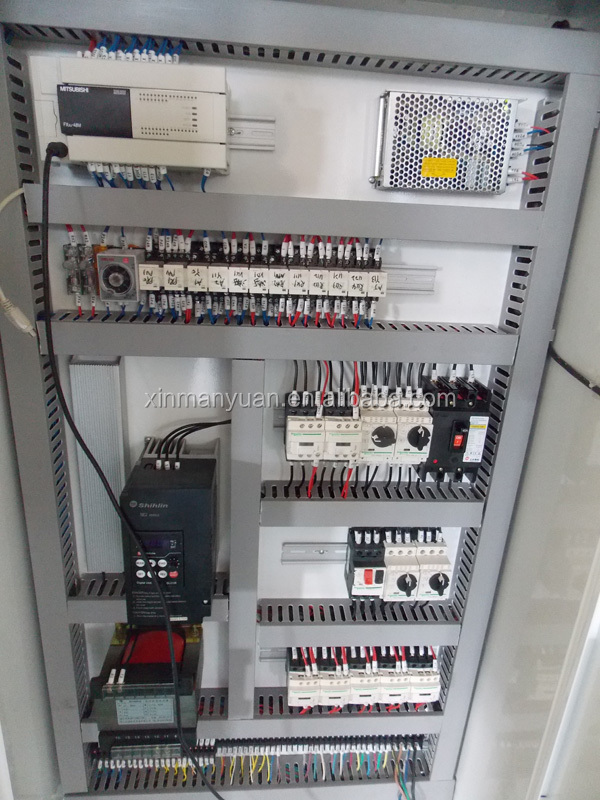

PLC:

-

from Japan mitsubishi

-

motors:

-

from taiwan teco

-

Rewind paper core inner dia:

-

0.5",1",1.5",2" are available(or as request)

-

touch panel:

-

from Taiwan

-

auto lift up system:

-

auto loading via motor

-

Cylinder:

-

Airtac from Taiwan

-

Air pressure valve:

-

SMC from Japan

-

unwind methond:

-

shaftless type

-

Frequency Inverter motor::

-

Yaskawa Inverter

Quick Details

-

Type:

-

Slitting Rewinder

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

PLC:

-

from Japan mitsubishi

-

motors:

-

from taiwan teco

-

Rewind paper core inner dia:

-

0.5",1",1.5",2" are available(or as request)

-

touch panel:

-

from Taiwan

-

auto lift up system:

-

auto loading via motor

-

Cylinder:

-

Airtac from Taiwan

-

Air pressure valve:

-

SMC from Japan

-

unwind methond:

-

shaftless type

-

Frequency Inverter motor::

-

Yaskawa Inverter

XMY-FQ1000 Thermal POS paper roll cutter

Application of Thermal POS paper roll cutter

Thermal Paper, Cash Register Paper, Fax Paper, ATM Paper, Bond Paper, Nonwoven Cloth Caronless Paper,Concern Paper,Queuing Paper,Air Ticket Paper, Boarding Paper, Movie Paper, etc

Main parameters of Thermal POS paper roll cutter

| Model | XMY-FQ1000 |

| Effective width | 500mm-1600mm |

| Max rewinding diameter | 200mm |

| Max unwinding diameter | 1000mm or as requests |

| Min slitting width | 20mm |

| Paper core I.D | 0.5",1",1.5",2"or as request |

| Max Speed | 200M/min |

| Motor | 5Hp |

The superior of Thermal POS paper roll cutter

1) All the parts are processed by CNC lathe,which will be with high precision.

2) All transmission rollers have been dynamic/static balance treated.

3) It is with Airtac cylinder and SMC air pressure valve,it will avoid overlap problem.

4) Automatic loading system is for loading heavy jumbo onto unwinding stand,save time and reduce labor intensity.

-Main Functions of Thermal POS paper roll cutter

1.Main motor: driven by one A.C motor with 2 stages type length counter to make machine stops accurately.

2.Rewind device: Rewind controlled by 3 surface rollers, and surface tension is adjustable for different materials and request.

3. Electricity Device: Equipped with 2 stage preset length counter, which provide machine stops accurately and smoothly.

4. Rewind Mode: Equipped with separated shaft type unwind base, auto web guide and auto unwind tension controlled.

5. Unwind Base: Separate type with hydraulic core chunk can be equipped for effcient and quick performance on jumbo roll change.

-Optional Parts of Thermal POS paper roll cutter

1.Unwind Pick Up Lift : for loading jumbo roll on the machine quickly and time saving.

2.Slitting Device: Able to be equipped with air score knife and trim removable unit for trimming at both side and size slitting.

Certification:

After-service:

1. Warranty for machines is 12 months and lifetime maintence.

2. A promptly reply within 24 hours.

3. Free usage training before delivering machines in factory.

More details,pls contact us freely !

Power part:

Back view:

Slitting part:

Side view:

Electrionic carbit

Front view:

Side view: