- Product Details

- {{item.text}}

Quick Details

-

Features:

-

high effecient

-

Dimension(L*W*H):

-

1050*1050

-

Applicable Industries:

-

Other

-

Weight (KG):

-

2385 KG

-

Warranty of core components:

-

6 month

-

Keyword:

-

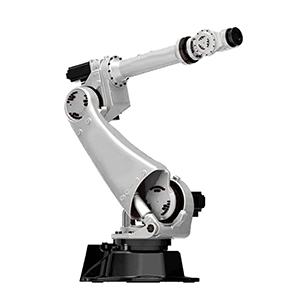

KuKa Manipulator

-

Number of axis:

-

6

-

Controller:

-

KR C5

-

Payload:

-

2826kg

-

Max payload:

-

611 kg

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KUKA

-

Application:

-

Industry

-

Features:

-

high effecient

-

Dimension(L*W*H):

-

1050*1050

-

Applicable Industries:

-

Other

-

Weight (KG):

-

2385 KG

-

Warranty of core components:

-

6 month

-

Keyword:

-

KuKa Manipulator

-

Number of axis:

-

6

-

Controller:

-

KR C5

-

Payload:

-

2826kg

-

Max payload:

-

611 kg

Product Description

|

Max reach

|

6750ml

|

|

Max payload

|

500 kg

|

|

Operating weight

|

611 kg

|

|

Number of axes

|

6

|

|

Mounting position

|

Floor

|

|

Footprint

|

1050mm*1050mm

|

|

Weight

|

approx.2385 kg

|

|

Controller

|

KR C5

|

A brief introduction of the product

Transportation industrial robots are mainly used in grinding, polishing, loading and blanking onto/from machine tools, automatic

transportation for stamping automatic production lines, etc. The transportation robot is an automatic product which uses robot’s

motion track to replace manual transportation. Its advantage is that it can accomplish all kinds of expected tasks by programming.

It combines the advantages of both human and machine in its structure and performance, especially embodying artificial

intelligence and adaptability.

transportation for stamping automatic production lines, etc. The transportation robot is an automatic product which uses robot’s

motion track to replace manual transportation. Its advantage is that it can accomplish all kinds of expected tasks by programming.

It combines the advantages of both human and machine in its structure and performance, especially embodying artificial

intelligence and adaptability.

Transfer robot

Welding robot

Stamping machine

Cooperative Robot

Conveyor line

Positioner

Silo

Ground track

Specification

|

Standard specifications

|

MOTOMAN-GP400R

|

|

|

|

model

|

YR-1-06VR400-A00

|

|

|

|

structure

|

Vertical multi joint type (6 degrees of freedom)

|

|

|

|

Portable quality * 1

|

Hand head

|

600kg/400kg

|

|

|

|

On the U-arm

|

10kg/30kg

|

|

|

Up to

|

3518 mm/2446mm

|

|

|

|

Repetitive positioning accuracy * 2

|

0.1mm/0.05mm

|

|

|

|

Action range

|

S-axis (rotation)

|

-150-+150

|

|

|

|

L-axis (lower arm)

|

-122 ° -+20 °

|

|

|

|

U-axis (upper arm)

|

-9° -+120 °

|

|

|

|

R-axis (wrist rotation)

|

-360°-+360°

|

|

|

|

B-axis (wrist swing)

|

-120 ° -+120 °

|

|

|

|

T-axis (wrist rotation)

|

-360 ° -+360°

|

|

|

|

S-axis (rotation)

|

1.40rad/s, 80 °/s

|

|

|

|

L-axis (lower arm)

|

1.40rad/s, 80 °/s

|

|

|

|

U-axis (upper arm)

|

1.40rad/s, 80 °/s

|

|

|

|

R-axis (wrist rotation)

|

1.40rad/s, 80 °/s

|

|

|

|

B-axis (wrist swing)

|

1.40rad/s, 80 °/s

|

|

|

|

T-axis (wrist rotation)

|

2.79rad/s, 160 °/s

|

|

|

Allowable torque

|

R-axis (wrist rotation)

|

1960N. m

|

|

|

|

B-axis (wrist swing)

|

1960N. m

|

|

|

|

T-axis (wrist rotation)

|

833N .m

|

|

|

Allowable moment of inertia

|

R-axis (wrist rotation)

|

150kg.m2

|

|

|

|

B-axis (wrist movement)

|

150kg.m2

|

|

|

|

T-axis (wrist rotation)

|

50kg.m2

|

|

|

Body quality

|

3560kg

|

|

|

|

Protection level

|

Body: IP54, wrist shaft: IP67

|

|

|

|

Installation environment

|

temperature

|

0 ° -+45 °

|

|

|

|

humidity

|

20% -80% RH (without condensation)

|

|

|

|

move

|

Below 4.9m/s2 (0.5G)

|

|

|

|

other

|

Do not have flammable or corrosive gases, and keep liquids away from electrical noise sources

|

|

|

Power capacity * 3

|

7.0kVA

|

|

|

|

Installation method * 4

|

Rack mounted

|

|

|

|

purpose

|

Handling, picking/packaging, palletizing, assembly/repackaging

|

|

|

|

|

*1; JIS B 8432 as the benchmark。

*2: The action range of the self axis is recorded instead of the ground reference.

*3: The purpose of meat varies depending on the

action mode. (Note) This table is recorded in the SI unit system |

|

|

|

project

|

specifications

|

|

|

|

name

|

MOTOMAN-MCL165

|

|

|

|

model

|

YR-MCL0165-A00

|

|

|

|

structure

|

Vertical multi joint shape (6 degrees of freedom)

|

|

|

|

load

|

165kg

|

|

|

|

Repetitive positioning accuracy * 1

|

+0.2mm

|

|

|

|

|

S-axis (rotation)

|

-150 °~+150 °

|

|

|

|

L-axis (lower wrist)

|

-60 °~+76 °

|

|

|

|

U (upper wrist)

|

-130 °~+240

|

|

|

|

R-axis (arm rotation)

|

-360~+360 °

|

|

|

|

B-axis (arm swing)

|

-130 °~+130

|

|

|

|

T-axis (arm rotation)

|

-360 °~+360 °

|

|

|

Maximum speed

|

S-axis (rotation)

|

1.92rad/s, 110s

|

|

|

|

L-axis (lower wrist)

|

1.92rad/s, 110s

|

|

|

|

U (upper wrist)

|

1.92 rad/s, 110% s

|

|

|

|

R-axis (arm rotation)

|

3.05rad/s, 175 °/s

|

|

|

|

B-axis (arm swing)

|

2.53rad/s, 145 ° s

|

|

|

|

T-axis (arm rotation)

|

4.19rad/s, 240 °/s

|

|

|

Allowable torque

|

R-axis (arm rotation)

|

883N-m

|

|

|

|

B-axis (arm swing)

|

883N-m

|

|

|

|

T-axis (arm rotation)

|

490N·m

|

|

|

Customer allowable moment of inertia

(CD2/4) |

R-axis (arm rotation)

|

51.25kg-m2

|

|

|

|

B-axis (arm swing)

|

51.25kg-m2

|

|

|

|

T-axis (arm rotation)

|

15kg-m2

|

|

|

Standard spray colors

|

Munsell N9.5

|

|

|

|

Body quality

|

1300kg

|

|

|

|

Cleanliness

|

IS06

|

|

|

|

|

temperature

|

+15~+35 ° C

|

|

|

|

humidity

|

20~80% RH (without condensation)

|

|

|

|

vibration

|

Below 4.9m/s2

|

|

|

|

other

|

The environment does not contain flammable or corrosive gases or liquids

Stay away from water Stay away from electronic noise sources The horizontal flatness of the installation robot is within 0.5mm |

|

|

Power capacity * 3

|

6.0kVA

|

|

|

|

project

|

specifications

|

|

|

|

name

|

TR8-E

|

|

|

|

Action range

|

818mm

|

|

|

|

Maximum load

|

8kg

|

|

|

|

|

S-axis (rotation)

|

170 °,+170 °

|

|

|

|

L-axis (lower arm)

|

-65 °,+145

|

|

|

|

U-axis (upper arm)

|

-113 °,+255 °

|

|

|

|

R-axis (wrist rotation)

|

-190 °,+190 °

|

|

|

|

B-axis (wrist swing)

|

-135 °,+135 °

|

|

|

|

T-axis (wrist rotation)

|

360 °,+360°

|

|

|

|

S-axis (rotation)

|

455/s

|

|

|

|

L-axis (lower arm)

|

385s

|

|

|

|

U-axis (upper arm)

|

520 °/s

|

|

|

|

R-axis (wrist rotation)

|

550/s

|

|

|

|

B-axis (wrist swing)

|

550/s

|

|

|

|

T-axis (wrist rotation)

|

1000 °/s

|

|

|

Permissible torque

|

R-axis (wrist rotation)

|

17N-m

|

|

|

|

B-axis (wrist swing)

|

17N-m

|

|

|

|

T-axis (wrist rotation)

|

10N-m

|

|

|

quality

|

39kg

|

|

|

|

Internal equipment cables

|

twelve

|

|

|

|

Built in trachea

|

2 (6)

|

|

|

|

Protective structure

|

IP67

|

|

|

|

Repetitive positioning accuracy

|

+0.02mm

|

|

|

|

Installation method

|

Floor, wall mounted, inclined, upside down

|

|

|

|

|

Temperature

|

0-45 ° C

|

|

|

|

Humidity

|

20~80% RH (free of knots

|

|

|

|

Morning acceleration

|

below 4.9m/s2 (0.5G)

|

|

|

|

Altitude

|

below 1000m

|

|

|

|

other

|

Non ignitable and corrosive gas safety

No splashing, less oil, and dust away from electromagnetic sources. Stay away from magnetic fields |

|

|

Power capacity

|

1.0kVA

|

|

|

|

Standard specifications

|

MOTOMAN-HC10DT

|

|

|

|

model

|

YR-1-06VXHC10-A10

|

|

|

|

DTB

|

move

|

|

|

|

structure

|

Vertical multi joint type (6 degrees of freedom)

|

|

|

|

Portable quality * 1

|

10kg

|

|

|

|

Up to

|

1200 mm

|

|

|

|

Repetitive positioning accuracy * 2

|

0.1mm

|

|

|

|

Action range

|

S-axis (rotation)

|

-180 ° -+180 °

|

|

|

|

L-axis (lower)

|

-180 ° -+180 °

|

|

|

|

U-axis (upper arm)

|

-5°-+355°

|

|

|

|

R-axis (wrist rotation)

|

-180 ° -+180 °

|

|

|

|

B-axis (wrist swing)

|

-180 ° -+180 °

|

|

|

|

T-axis (wrist rotation)

|

-180 ° -+180 °

|

|

|

Maximum speed

|

S-axis (rotation)

|

2.27rad/s, 130°/s

|

|

|

|

L-axis (lower)

|

2.27rad/s, 130°/s

|

|

|

|

U-axis (upper arm)

|

3.14rad/s, 180s

|

|

|

|

R-axis (wrist rotation)

|

3.14rad/s, 180° s

|

|

|

|

B-axis (wrist swing)

|

4.36rad/s, 250°/s

|

|

|

|

T-axis (wrist rotation)

|

4.36rad/s, 250°/s

|

|

|

Maximum speed at the tip position

|

Effective coordination operation

|

250mm/s

|

|

|

|

Invalid cooperative operation

|

1000mm/s

|

|

|

Allowable torque

|

R-axis (wrist rotation)

|

27.4N. m

|

|

|

|

B-axis (wrist swing)

|

27.4N. m

|

|

|

|

T-axis (wrist rotation)

|

9.8N. m

|

|

|

Permissible moment of inertia (GD2/4)

|

R-axis (wrist rotation)

|

0.78kg.m2

|

|

|

|

B-axis (wrist swing)

|

0.78kg.m2

|

|

|

|

T-axis (wrist rotation)

|

0.10kg.m2

|

|

|

Body quality

|

48kg

|

|

|

|

Protection level

|

IP20

|

|

|

|

Installation environment

|

temperature

|

0 ° -+40*

|

|

|

|

humidity

|

20% -80% RH (without condensation)

|

|

|

|

shock

|

Below 4.9m/s2 (0.5G)

|

|

|

|

other :Do not have flammable or corrosive gases, and keep liquids away from electrical noise sources

|

|

|

|

Power capacity * 3

|

1.0kVA

|

|

|

|

Installation method * 4

|

Floor mounted, upside down, wall mounted, inclined

|

|

|

|

purpose

|

Handling, picking/packaging, palletizing, assembly/repackaging

|

|

|

|

Remarks

|

*1: JIS B 8432 as benchmark

*2: Recorded the range of motion of the self axis rather than the ground reference *3: Depending on the purpose and action mode. (Note) This table is recorded in the SI unit system |

|

|

|

Standard specification

|

Motomini

|

|

|

|

Model

|

YR-1-06VX05-A00

|

|

|

|

Construction

|

Vertical multi joint type (6 degrees of freedom)

|

|

|

|

Portable mass * 1

|

0.5kg

|

|

|

|

Repetitive positioning accuracy * 2

|

0.02mm

|

|

|

|

Action range

|

S-axis (rotation)

|

-170°-+170°

|

|

|

|

L-axis (lower)

|

85°-+90°

|

|

|

|

U-axis (upper arm)

|

-50°-+90

|

|

|

|

R-axis (wrist rotation)

|

-140°-+140°

|

|

|

|

B-axis (wrist swing)

|

30°-+210

|

|

|

|

T-axis (wrist rotation)

|

360*-+360

|

|

|

Maximum speed

|

S-axis (rotation)

|

5.5rad/s/315°/s

|

|

|

|

L-axis (lower)

|

5.5rad/s,315*/s

|

|

|

|

U-axis (upper arm)

|

7.3rad/s.420°/s

|

|

|

|

R-axis (wrist rotation)

|

10.5rad/s600°/s

|

|

|

|

B-axis (wrist swing)

|

10.5rad/s.600°/s

|

|

|

|

T-axis (wrist rotation)

|

10.5rad/s600°/s

|

|

|

Allowable torque

|

R-axis (wrist rotation)

|

0.42N.m

|

|

|

|

B-axis (wrist swing)

|

0.42N.m

|

|

|

|

T-axis (wrist rotation)

|

0.37N.m

|

|

|

Permissible moment of inertia (GD2/4)

|

R-axis (wrist rotation)

|

0.0078kg/m2

|

|

|

|

B-axis (wrist swing)

|

0.0078kg/m2

|

|

|

|

T-axis (wrist rotation)

|

0.00299kg.m2

|

|

|

Body quality

|

7kg

|

|

|

|

Protection level

|

IP20

|

|

|

|

Installation environment

|

temperature

|

0 ° -+40*

|

|

|

|

humidity

|

20% -80% RH (without condensation)

|

|

|

|

shock

|

Below 4.9m/s2 (0.5G)

|

|

|

|

other :Do not have flammable or corrosive gases, and keep liquids away from electrical noise sources

|

|

|

|

Installation method * 4

|

Floor mounted, upside down, wall mounted, inclined

|

|

|

|

purpose

|

Handling, picking/packaging, palletizing, assembly/repackaging

|

|

|

|

Standard specifications

|

MOTOMAN-GP280

|

|

|

|

model

|

YR-1-06VX280A00

|

|

|

|

structure

|

Vertical multi joint type (6 degrees of freedom)

|

|

|

|

Portable quality * 1

|

Hand head

|

280kg

|

|

|

|

On the U-arm

|

30kg

|

|

|

Up to

|

2446mm

|

|

|

|

Repetitive positioning accuracy * 2

|

0.05mm

|

|

|

|

Action range

|

S-axis (rotation)

|

-180°- +180

|

|

|

|

L-axis (lower arm)

|

60°-+76

|

|

|

|

U-axis (upper arm)

|

77.8°- +197

|

|

|

|

R-axis (wrist rotation)

|

360*- +360

|

|

|

|

B-axis (wrist swing)

|

125*- +125°

|

|

|

|

T-axis (wrist rotation)

|

360*-+360

|

|

|

Maximum speed

|

S-axis (rotation)

|

1.57rad/s90°/s

|

|

|

|

L-axis (lower arm)

|

1.39rad/s,80°/s

|

|

|

|

U-axis (upper arm)

|

1.57rad/s,90°/s

|

|

|

|

R-axis (wrist rotation)

|

2.01rad/s,115°/s

|

|

|

|

B-axis (wrist swing)

|

1.92rad/s,110°/s

|

|

|

|

T-axis (wrist rotation)

|

3.32rad/s,190°/s

|

|

|

Allowable torque

|

R-axis (wrist rotation)

|

1333N.m

|

|

|

|

B-axis (wrist swing)

|

1333N.m

|

|

|

|

T-axis (wrist rotation)

|

706N.m

|

|

|

Allowable moment of inertia

(GD2/4) |

R-axis (wrist rotation)

|

142kg.m2

|

|

|

|

B-axis (wrist movement)

|

142kg.m2

|

|

|

|

T-axis (wrist rotation)

|

79kg.m2

|

|

|

Body quality

|

1300kg

|

|

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches