- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220/380V 50/60Hz

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Xiepai

-

Dimension(L*W*H):

-

2200*1500*1800mm

-

Weight:

-

350 KG

-

Keywords:

-

chubby gorilla filling capping machine

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Filling range:

-

10-100ml

-

Filling nozzles:

-

Customized Nozzle

-

Cap type:

-

Screwing/Crimping/Pressing

-

Marketing Type:

-

Other

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Wooden Case

-

Filling Material:

-

Oil, Perfume, Essential Oil, chubby gorilla oil

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220/380V 50/60Hz

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Xiepai

-

Dimension(L*W*H):

-

2200*1500*1800mm

-

Weight:

-

350 KG

-

Keywords:

-

chubby gorilla filling capping machine

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Filling range:

-

10-100ml

-

Filling nozzles:

-

Customized Nozzle

-

Cap type:

-

Screwing/Crimping/Pressing

-

Marketing Type:

-

Other

Products Description

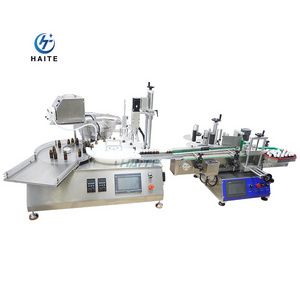

Chubby Gorrila Bottle Filling Capping Machine

This automated line, apt for processing plastic vessels of 10ml to 120ml, is assembled from a high-precision cam indexing mechanism, equal plate for positioning and filling, pressure-based internal capping, and an external capping apparatus. It integrates an adjustable-torque motor capper, volumetric or peristaltic pump for precise filling, and touchscreen control for intelligent operation—no filling without a bottle present, no capping sans cap.

The system takes pride in its flawless transmission, precise positioning, accurate measurements, and straightforward operation. Internal and external caps are meticulously aligned with the authoritative mold, ensuring an elevated success rate. Given the output demands, the sorting elements can be tailored for single or twin-track feeding, thereby synchronizing with the system's overall efficiency.

Please let me know if you need any specific information or assistance related to this machine.

Application

Technical Parameters

|

Product

|

Chubby Gorrila Bottle Filling Capping Machine

|

|

Output

|

1500-4000BPH(customizable)

|

|

Filling Volume

|

10-100ml

|

|

Control

|

PLC and Touch Screen

|

|

Filling nozzles

|

2-8(Customized)

|

|

Cap Feeding

|

Elevator

|

|

Cap Motor

|

Magnetic Motor

|

|

Torquing Range

|

0-100N

|

|

Loading Way

|

Motor Pump Loading

|

|

Capping Type

|

Screw, Pressing, Crimping, etc

|

|

Bottle Type

|

Glass, Plastic, Metal, etc

|

|

Driving Motor

|

Servo Motor

|

|

Power

|

1.8KW

|

|

Voltage

|

220/380V, 50/60Hz

|

|

Machine Frame Material

|

SS304

|

Details Images

A Different Bottle Feeding Tables

BOTTLE FEEDING TABLE

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output tunnel, the machine will be able to work with different size bottle.

A Different Filling Nozzle

Filling Nozzle

The linear-type filling is adopted. When a bottle gets to the filling station, it will be automatically stopped, the filling head moves down, and the filling is started, and the filling needle will rise along the liquid level. There is the optoelectronic sensor, there is no filling when there is no bottle, and the waste is avoided.

Different Capping stations

Capping stations

When the bottle finish filling and rotate to the cap feeding station, the cap feeding rod moving downward driven by the cylinder, the hollow part of the rod will be evacuated to suck the cap, causing the cap to fall along the mold, and ensure the accuracy of the cap feeding.

Cap Sorter

The cap oscillation module is a vital component responsible for managing the alignment and delivery of caps in the bottling process,and feed them to the bottle through cap feeding tunnel, no need to put manually one by one, it can also equipped with sound-proof enclosure or cap replenish elevator with hopper according to customer production requirement.

The motor and electronic components are comprised of globally recognized brands, with the option for customization to meet specific customer requirements.

We'll change into your standard plug before shipping,such as American plug, UK plug, European plug...

A Series Of Installation And Technical Guide Videos, Easy To Learn

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches