- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4150*1250*2200mm

-

Year:

-

2020

-

Power (kW):

-

45 kW

-

Weight (KG):

-

6000 KG

-

Raw material:

-

Rubber

-

Application:

-

Rubber Processing Machinery

-

Name:

-

Waste Tire Recycling Plant

-

Function:

-

Tire Powder Recycling Machine

-

End product:

-

Rubber Particle

-

Product name:

-

Waste Tyre Pyrolysis Machine

-

Usage:

-

Used Tire Recyling

-

Machine Type:

-

Semi-automatically

-

Capacity:

-

5-6T

-

Color:

-

Customer Requirement

-

Certification:

-

CE ISO TUV

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LDT

-

Voltage:

-

380V/50HZ or Customized

-

Dimension(L*W*H):

-

4150*1250*2200mm

-

Year:

-

2020

-

Power (kW):

-

45 kW

-

Weight (KG):

-

6000 KG

-

Raw material:

-

Rubber

-

Application:

-

Rubber Processing Machinery

-

Name:

-

Waste Tire Recycling Plant

-

Function:

-

Tire Powder Recycling Machine

-

End product:

-

Rubber Particle

-

Product name:

-

Waste Tyre Pyrolysis Machine

-

Usage:

-

Used Tire Recyling

-

Machine Type:

-

Semi-automatically

-

Capacity:

-

5-6T

-

Color:

-

Customer Requirement

-

Certification:

-

CE ISO TUV

Parameters

|

Model

|

Blade Specifications (mm)

|

Blade (pcs)

|

Reducer

(set )

|

Motor Power (Kw)

|

Spindle Speeds

(r/min)

|

Dimensions

|

|

LDT600

|

F 250*10

|

48

|

400*2

|

15*2

|

18-25

|

1450*870*2200

|

|

LDT800

|

F 250*20

|

32

|

400*2

|

30*2

|

18-25

|

2150*870*2200

|

|

LDT1000

|

F 350*30

|

28

|

650*2

|

37*2

|

18-25

|

3400*1250*2200

|

|

LDT1200

|

F 350*30

|

38

|

650*2

|

55*2

|

18-25

|

4150*1250*2200

|

|

LDT1500

|

F 400*40

|

36

|

750*2

|

75*2

|

18-25

|

4150*1250*2200

|

|

LDT2000

|

F 530*50

|

38

|

850*2

|

90*2

|

18-25

|

5250*1780*2200

|

Our Advantages

Features:

1. Use thick and heavy duty knives, high shredding efficiency.

2. Moving and fixed knives are made of alloy steel, can resistance to high torque, high strength and very durable.

3. Entire frame made up by thick steel board, low maintainance, economy and durability.

4. Full automatic 24 hours continuous running plant with water cooling system, small space; Low energy consumption, No polluted water; No waste gas; No waste residue; high efficiency.

5. Configuration adjustable according to different requirements.

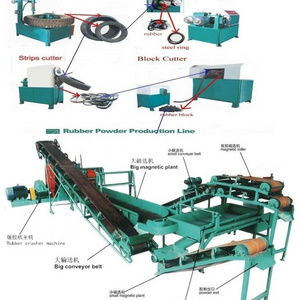

Whole Tire Recycling Process:

1. Separate steel in sidewall (clean steel for direct selling).

2. Entire tires shred to 5 cm rubber pieces, through firstly steel wire separation system.

3. 5 cm rubber pieces crushed into small rubber crumbs, through second steel wire separation get 98% pure steel wire. (Steel wire cleaning plant available for higher request on steel wire purity).

4. Rubber crumbs grind into rubber powder as required size.

5. Fiber separated.

3D Flowchart Of Automatic Waste Tire Recycling Production Line:

Application & Case

Cases:

Waste Tire Recycling Production Line For Rubber Granules

Capacity: 1-1.5TPH

Final Products: 1-10mm Rubber Granules

Main Processes: Belt Conveyor - Roller Tire shredder Machine - Belt Conveyor - Rubber & Steel Wire Separating Machine - Belt Conveyor -Granulator

Final Products: 1-10mm Rubber Granules

Main Processes: Belt Conveyor - Roller Tire shredder Machine - Belt Conveyor - Rubber & Steel Wire Separating Machine - Belt Conveyor -Granulator

Certifications & Customer Visiting

Customer Visiting:

Packaging & Shipping

Our Factory:

Why Choose Us

1. Are you manufacturer or trading company?

We are manufacturer with 26 years experience on machines. Luodate machines were exported by trading companies to more than 20 countries, supplying full technical support and solutions, timely and professional service.

2. How do you assistant to install the machine on worksite?

We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation, commissioning.

3. How can I get spare parts for replacement in other countries?

Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent or by sea within 5days.

4. Can I use mark machine with different logo and color?

Yes, please confirm details with sales.

5. Can your customers test the machines?

Before the machines or production line leaving factory, we test machine for client with free of charge.

6. What will we do if we have problems in machine working after we buy the machine?

Luodate has people special for after-sale service, if customers outside China have problems when machine working, just feel free to send us the picture or video to show us, we will give you solutions in 24hours.

Hot Searches