- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Electric/ 6.5kw

-

Dimension(L*W*H):

-

W845x H1600 x D845

-

Weight (KG):

-

500

-

Application:

-

Metal Surface Finishing

-

Local Service Location:

-

Colombia

-

Usage:

-

Material Parts

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Keywords:

-

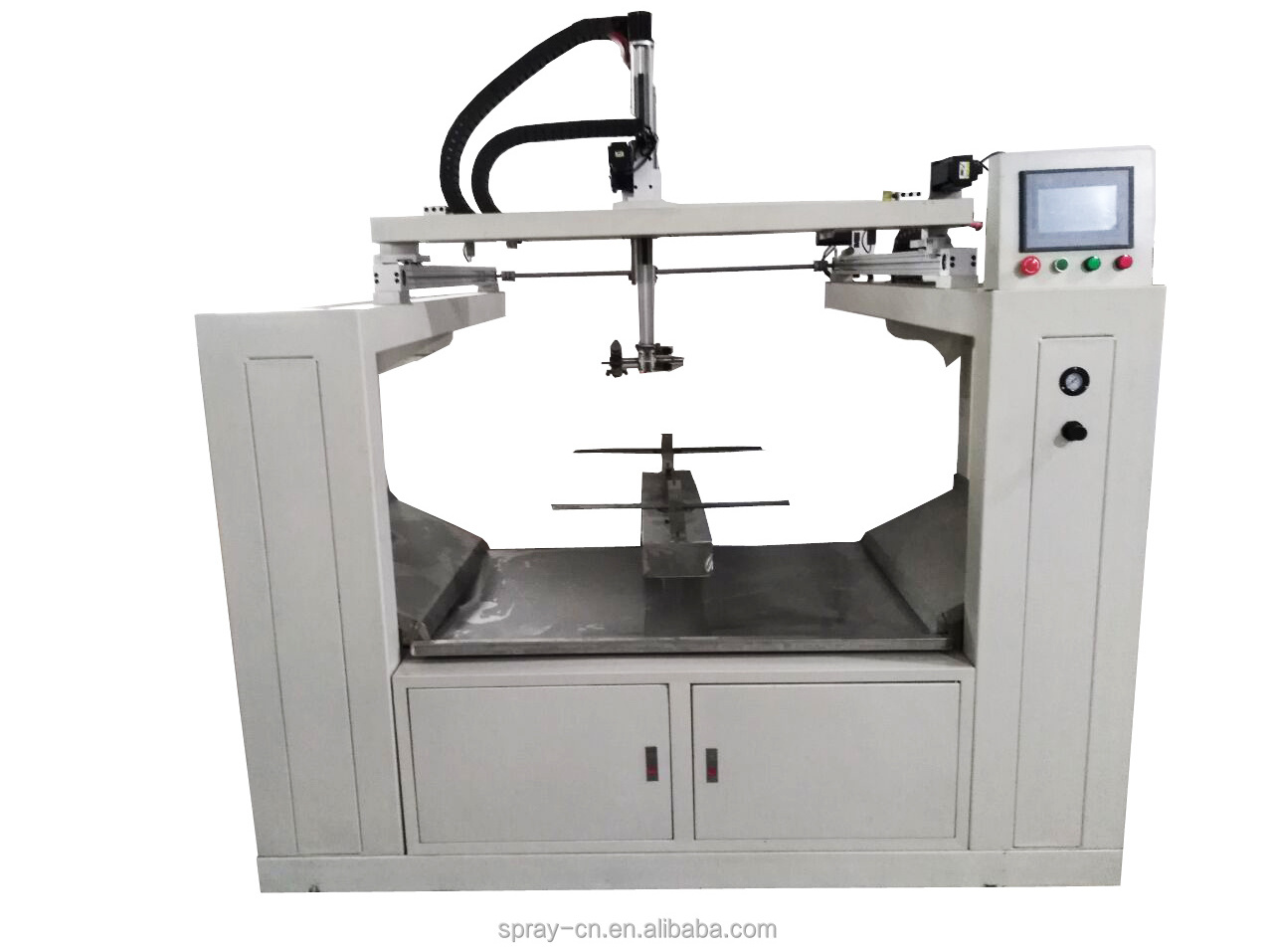

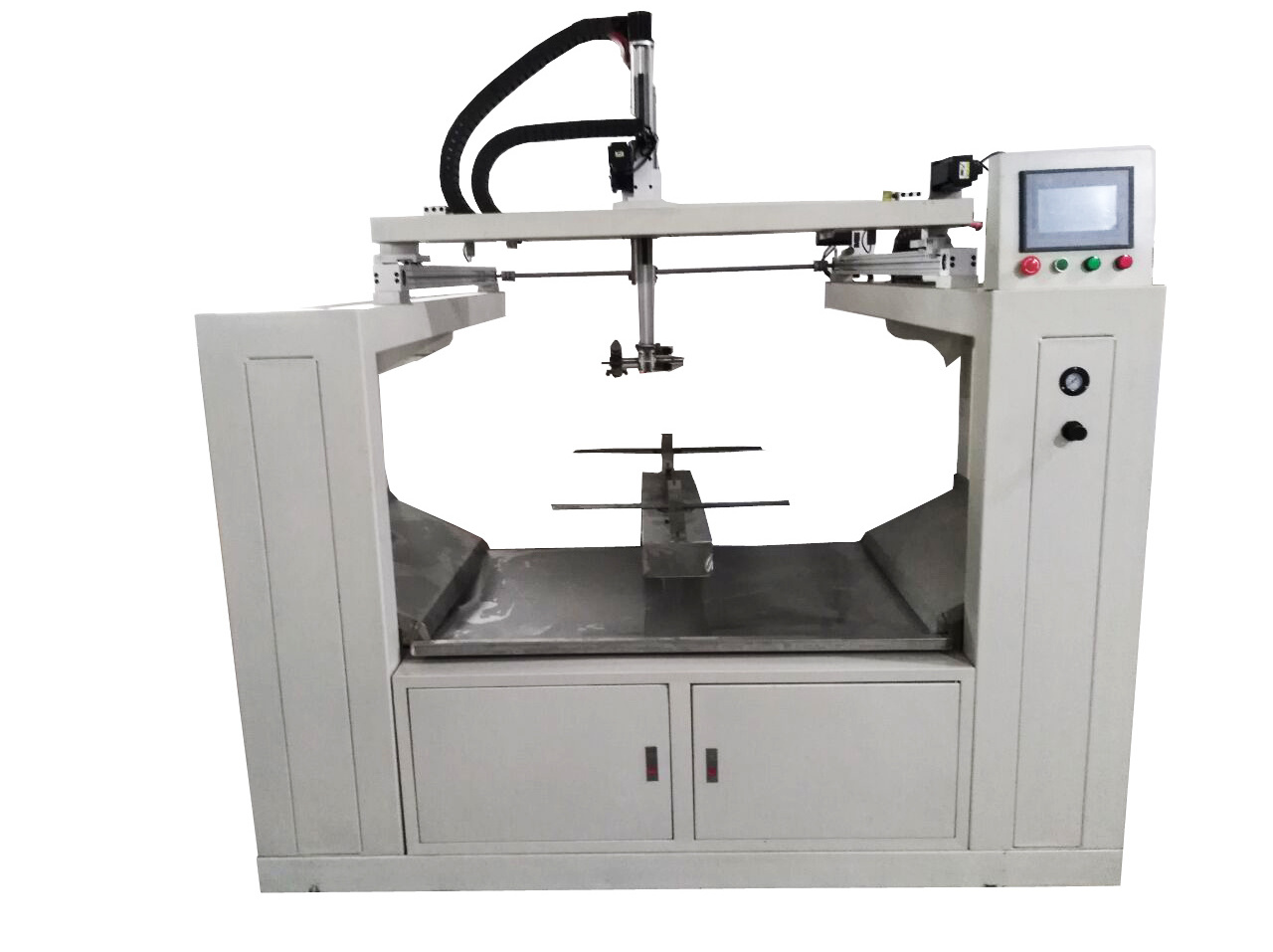

Manual Electrostatic Powder Spray Coating Machine

-

Spraying Guns:

-

Automatic Spraying Guns

-

Control System:

-

PLC+Touch Screen Automatic

-

Advantage:

-

Easy Operate

-

Color:

-

Cutomized

-

Function:

-

High Coating Efficiency

Quick Details

-

Machine Type:

-

3/5/6 axis auto spray paint machine, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Other

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINQINFENG

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Electric/ 6.5kw

-

Dimension(L*W*H):

-

W845x H1600 x D845

-

Weight (KG):

-

500

-

Application:

-

Metal Surface Finishing

-

Local Service Location:

-

Colombia

-

Usage:

-

Material Parts

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Keywords:

-

Manual Electrostatic Powder Spray Coating Machine

-

Spraying Guns:

-

Automatic Spraying Guns

-

Control System:

-

PLC+Touch Screen Automatic

-

Advantage:

-

Easy Operate

-

Color:

-

Cutomized

-

Function:

-

High Coating Efficiency

Evaporation coating equipment: vertical, horizontal. Machinable products include: mobile phone, DVD, MP3, PDA shells, buttons; cosmetic shells; craft gifts, toys, Christmas gifts; Machinable materials include: ABS, PS, PP, PC, PVC, nylon, metal, Poly , glass, ceramics, TPU, etc. The electroplating effects are: ordinary electroplating bright surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, colorful, etc.; electroplating colors are: gold, silver, red, blue, green, purple, etc.

Magnetron sputtering + evaporation coating equipment: vertical, horizontal. It is a multifunctional and efficient coating equipment. Rotary magnetron rake, middle rake twin sputtering rake, unbalanced magnetron sputtering rake, DC pulse superimposed bias power supply, etc. can be configured according to user requirements. , glass, ceramics, etc.) workpieces coated with aluminum, copper, chromium, titanium, silver, stainless steel and other metal films or non-metallic and metal-infiltrated DLC films, the coating layer is uniform, dense, and has strong adhesion and other characteristics, which can be widely used in Home appliances, clocks, arts and crafts, toys, car lamp reflectors, mobile phone button shells and instrumentation and other surface decorative coatings and functional coatings for tools and molds.

Multi-arc ion coating equipment: We have matured in the design and processing of this coating equipment, and have been stable in the coating and coating of tools for a variety of ultra-hard ceramic films, including titanium nitride (Tin), titanium carbide (Tic), titanium nitride (Titanium carbide) ( TiCn), zirconium nitride (Zrn), chromium nitride (Crn), titanium aluminum nitride (TiAln), etc. After proper film processing, the life of the workpiece can be increased by 3 to 10 times. It can reduce costs, increase production efficiency and improve product quality. Widely used: craft ceramics, cutting tool industry: such as carbide, drill, milling cutter and other cutting tools. Precision mold industry: standard punch molds, forming molds, etc. Automobile industry: easy-wear parts such as pistons and piston rings.

| Spray the base UV paint---UV Curing----PVD Vacuum coating machine----Spray the top UV paint---UV curing. |

Overview: Evaporative coating device uses resistance heating method in a vacuum chamber to melt and vaporize the metal wire (aluminum wire) that is close to the resistance wire, and the vaporized metal molecules are deposited on the substrate to obtain smooth and high reflection. The high-efficiency film layer achieves the purpose of decorating and beautifying the surface of the item.

Features: Reasonable structure, uniform film layer, good film quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance.

Uses: automobiles, audio, various small appliances, computers, watches, toys, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials: ABS, PS, PP, PC, PVC, Nylon, Metal, Poly, Glass, Ceramic, TPU, etc.