- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hubei, China

-

Control system:

-

PLC intelligent temperature controller

-

Raw material:

-

unglazed ceramic tile,hot melt film,tempered glass

-

Max working size:

-

1900mmX2500mm

-

Machine size:

-

3300*2330*1800mm

-

Packing size:

-

3300*2500*2000mm

-

Processing thickness:

-

3-20mm

-

Machine material:

-

steel

-

Tile life time:

-

same as ceramic tile

-

Surface:

-

glazed/gloosy

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Ceramic

-

Production Capacity:

-

9㎡ per hour

-

Place of Origin:

-

Hubei, China

-

Control system:

-

PLC intelligent temperature controller

-

Raw material:

-

unglazed ceramic tile,hot melt film,tempered glass

-

Max working size:

-

1900mmX2500mm

-

Machine size:

-

3300*2330*1800mm

-

Packing size:

-

3300*2500*2000mm

-

Processing thickness:

-

3-20mm

-

Machine material:

-

steel

-

Tile life time:

-

same as ceramic tile

-

Surface:

-

glazed/gloosy

New designs ceramic floor/wall tile making machine

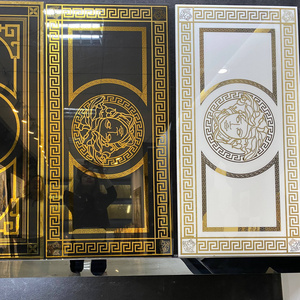

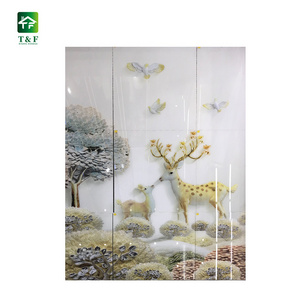

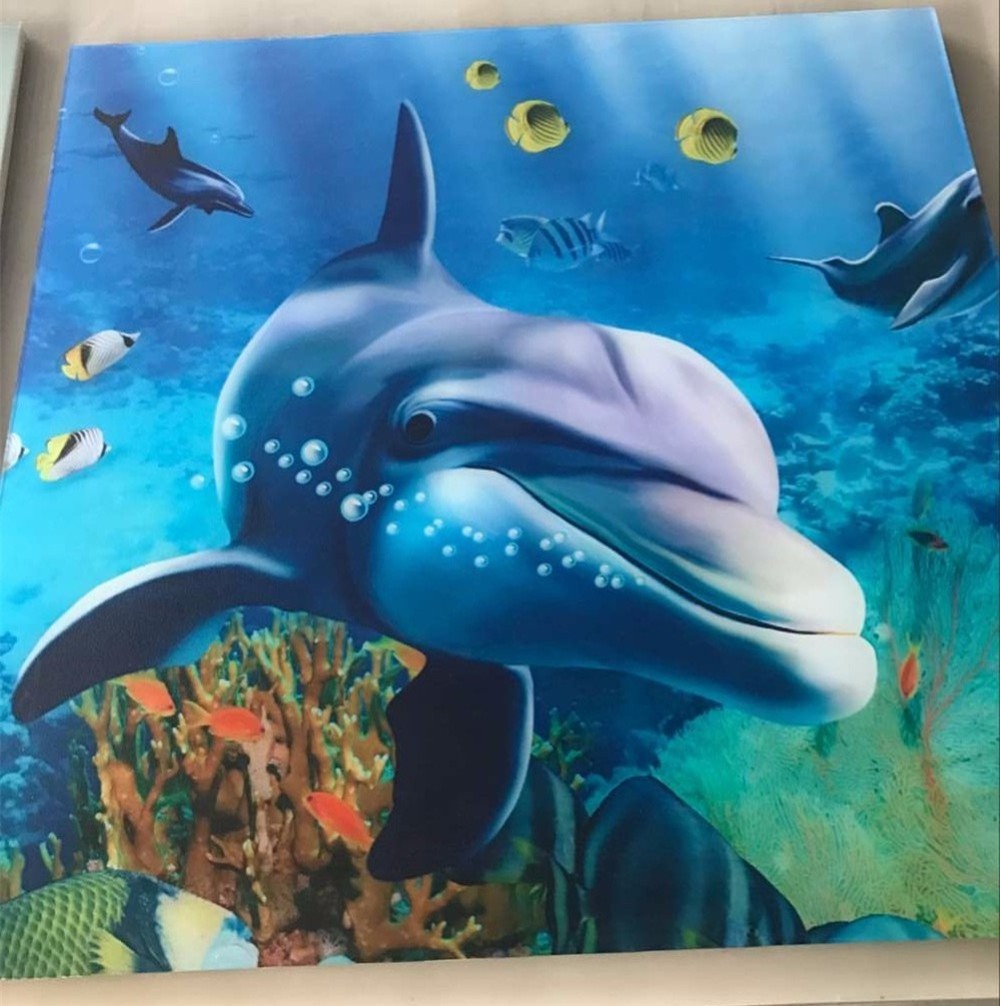

3D microcrystalline-glass ceramic tile is a composite of ceramic tiles and the microcrystalline-glass which has been printed personalized graphics by 3D high-definition printer in high temperature. And then grind edge and anti-skid to be finished.

The structure of the 3d glass ceramic tile

The advantage of the 3D microcrystalline-glass ceramic tile.

1.The three-dimensional effect is much stronger than the ordinary ceramic tile,

we fuse the ceramic and glass-ceramic together, through the glass refraction to the light to have a more vivid visual sense.

2.High strength, abrasion resistance, widely applications, unlimited using scope,

including interior and outdoor decoration, wall and ground decoration, wet and dry dual-use

3.Patterns can be customized (personalized customize).

Thousands of patterns including sea world, suspended wooden bridge, natural scenery, landscape painting, natural stone etc. Various sizes can be selected arbitrarily,or select complex designs of your own country decorating style

4.Never fade, easy to clean

. Patterns will never fading, scrubbing the tiles freely,and color lasting as new.

5. Healthy and environment friendly, easy to clean.

The product does not contain formaldehyde; non-toxic and tasteless; no radiation; corrosion resistance; anti-aging.Any dirt will take on a new look after gently rubbing.

6. Easily installation

, once installed can move in ,the same simple as traditional ceramic tiles installation,

new deisgns ceramic floor/wall tile making machine

1st 3D Microcrystalline galss ceramic tile forming machine

It is used to combine the microcrystalline glass and unglazed ceramic tile

Machine characteristics

1. The furnace body uses the steel structure, the furnace inside uses the high-grade heat preservation material combination to become the double protection.

2. The control system is an intelligent temperature controller, can be programmed to complete the whole process automatically and manually.

3. Use direct-connected vacuum pump, tear-resistant silicone plate that is durable in use, good air tightness, and can automatically keep the vacuum after power down.

4. The machine use finned heating pipe,cooling uniformity, long life, using brand circulation fan to circulate air heating , heating speed , temperature equalizing, high output; the entire heat cycles in the box,There are air vents and suction vents in the equipment, so that each vacuum bag on the upper and lower surface heat evenly, there is no dead heat, high yield.

5. Use Programmable intelligent control device, plc touch-screen control system, automatic start and stop, No staff is required to watch, and it will automatically prompt when break down.

6. Double working positions from left to right recycle, simple operation.

7. When the device is powered off ,the machine can automatically keep the vacuum, no need staff to watch, and can continue operating when power on.

1. The furnace body uses the steel structure, the furnace inside uses the high-grade heat preservation material combination to become the double protection.

2. The control system is an intelligent temperature controller, can be programmed to complete the whole process automatically and manually.

3. Use direct-connected vacuum pump, tear-resistant silicone plate that is durable in use, good air tightness, and can automatically keep the vacuum after power down.

4. The machine use finned heating pipe,cooling uniformity, long life, using brand circulation fan to circulate air heating , heating speed , temperature equalizing, high output; the entire heat cycles in the box,There are air vents and suction vents in the equipment, so that each vacuum bag on the upper and lower surface heat evenly, there is no dead heat, high yield.

5. Use Programmable intelligent control device, plc touch-screen control system, automatic start and stop, No staff is required to watch, and it will automatically prompt when break down.

6. Double working positions from left to right recycle, simple operation.

7. When the device is powered off ,the machine can automatically keep the vacuum, no need staff to watch, and can continue operating when power on.

2nd Glass ceramic tile printing machine

Machine characteristics:

1. Automatic lifting platform, easy to operate, reduce the alignment error

2. Mist spray or line spray printing method can be choose, line spray speed up, mist spray exquisite and lifelike to eliminate drawing dice

3. Three-stage scraping and peristaltic pump device to prevent nozzle clogging, extended nozzle life

4. Automatic cleaning and nozzle moisturizing device to ensure the fluency of the ink and prevent nozzle clogging

5. Any location can be set as the print origin, operation is simple and easy to learn

6. Silent linear guide, stable performance, high precision , pass the European CE certification, quality is guaranteed comparatively

7. Equipment printing platform has a scale to facilitate the visual measurement and display of the printed materials

8. Using imported LED-UV lamp, cold light source, no radiation, ultra-low power consumption, environment-friendly and energy-saving

9. Double servo motor, control the performance is more stable

3rd Ceramic tile grinding machine

Machine characteristics

1. The key parts of the machine adopts cast iron material, and is formed by natural effects processing which has the advantages of smooth, beautiful appearance, deformation and so on.

2. Method of clamping part imported from Italy PUPL synchronization with horizontal transfer, which greatly improve the precision of grinding, grinding parts adopt high-precision grinding head motor.

3. The configuration of the machine is chamfer with two wheels and flat two grinding wheels. It can realized the purpose of chamfer edge polishing and flat,edges and chamfers fine grinding.

For the production of the 3d micro-crystalline glass ceramic tile,we need to prepare the unglazed ceramic tile,3d micro crystallline glass and hot melt film paper

Unglazed ceramic tile

Normal unglazed ceramic tile

Can buy anywhere

3d microcrystalline glass

Packing :600 pcs /carton

Thickness: 1.8 mm used for wall

2.8 mm used for floor

Hot melt adhesive film paper

Size:0.6x100m

Thickness : 0.1 mm

operation video :

Second,use the hot met stick the ceramic tile and microcrystalline glass

Third,grind the tile by grind machine.

> Warranty: 1 Years.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged,

those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

> Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, please arrange board ,hotel,and other n

ecessary things.

> We will provide more than 1000 HQ designs free together with the machine.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q: How can I contact you?

A: Please look at my contact card. You can talk to me anytime. Or send me inquiry email, I will reply you in 24 hours and offer the optimum solution to you

Q: What is the status of After-sale Services for customers and machineries?

A: Engineers available to service machinery overseas. But the customers/buyer should pay for installation and commissioning fee $65/day . We will provide the technical support for the whole life of the equipment and free training.

Q: How to visit our company?

A: 1.Fly to Beijing airport: By high speed train From Beijing Xi to wuhan station (4 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to wuhan station (4.5 hours),then we can pick up you.

3.Fly to Guangzhou aiport: By air From Guangzhou south to wuhan; then we can pick up you.

4.Fly to Wuhan Tianhe Airport(about 1 hour to our factory),we can pick you up .then we can pick up you.

Contact me

Cynthia

Mobile/Wechat/WhatsApp:+86 13692109735

Hubei Tengcang Building Materials Technology Co., Ltd.