- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2300x1300x1700mm

-

Weight:

-

800 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Wood chipper

-

Applicable materials:

-

Dry or wet tree branches

-

Production capacity:

-

1-2 t

-

Applicable material diameter:

-

not more than 100mm

-

Discharge port:

-

360 degree rotating

-

Start mode:

-

Electric start

-

Tire size:

-

165/ 70R13

-

Feed port length:

-

1060 mm

-

Inside size of feed port:

-

300mm*200mm

-

HS code:

-

8436800090

Quick Details

-

Use:

-

crush wood into chips

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Corey

-

Dimension(L*W*H):

-

2300x1300x1700mm

-

Weight:

-

800 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Wood chipper

-

Applicable materials:

-

Dry or wet tree branches

-

Production capacity:

-

1-2 t

-

Applicable material diameter:

-

not more than 100mm

-

Discharge port:

-

360 degree rotating

-

Start mode:

-

Electric start

-

Tire size:

-

165/ 70R13

-

Feed port length:

-

1060 mm

-

Inside size of feed port:

-

300mm*200mm

-

HS code:

-

8436800090

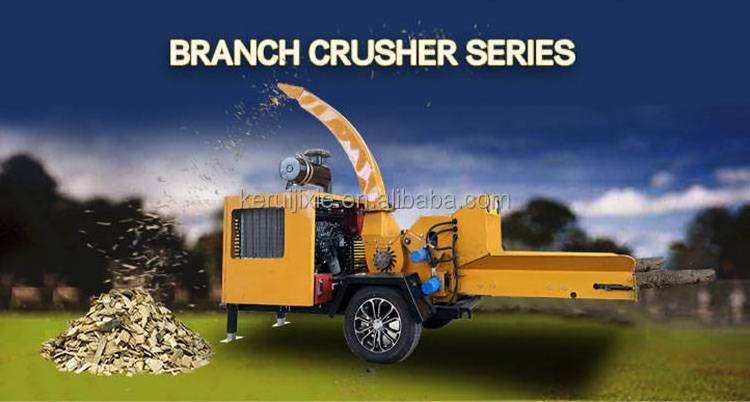

1.OVERVIEWS

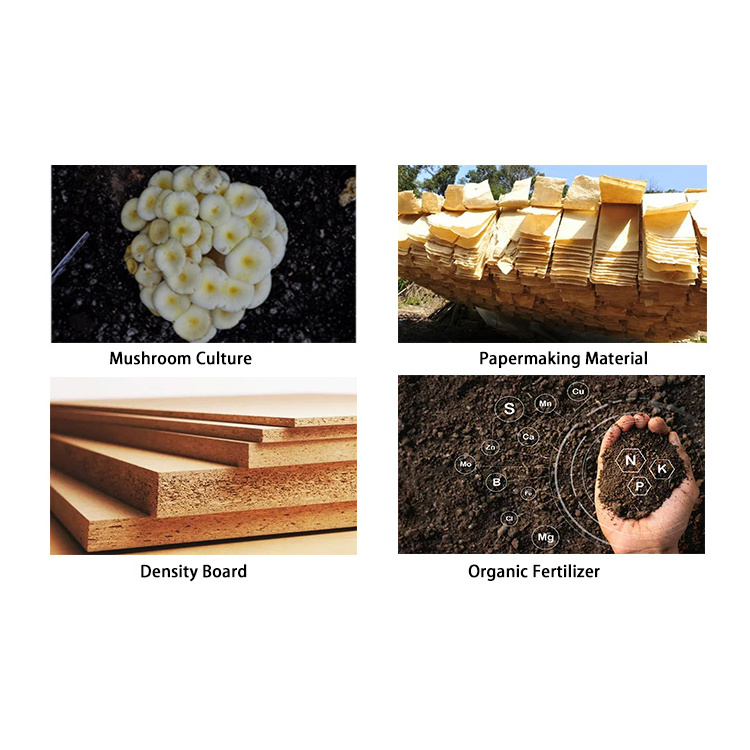

Corey branch pulverizer is divided into two types: electric drive and diesel drive. Such machines are usually

designed

with wheels so they are easy to carry and operate. Therefore, it is possible to move it easily to anyplace you want. It is light weight, but powerful. It is mainly used to crush various branches cut from trees. The finished materials can be used as mulch, garden bed foundation, organic fertilizer, edible fungi, biomass power generation, or be used to produce high-density board, particleboard, paper industry and so on.

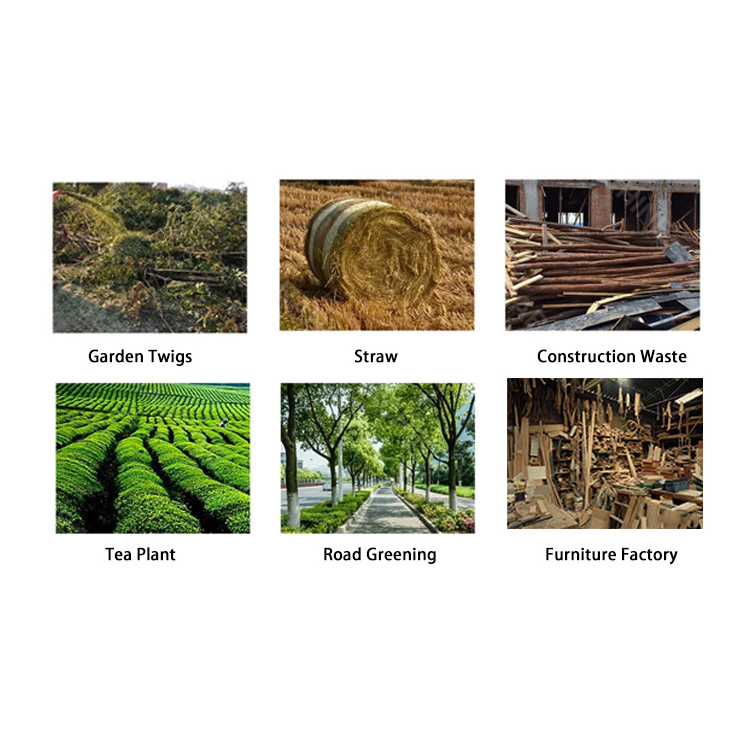

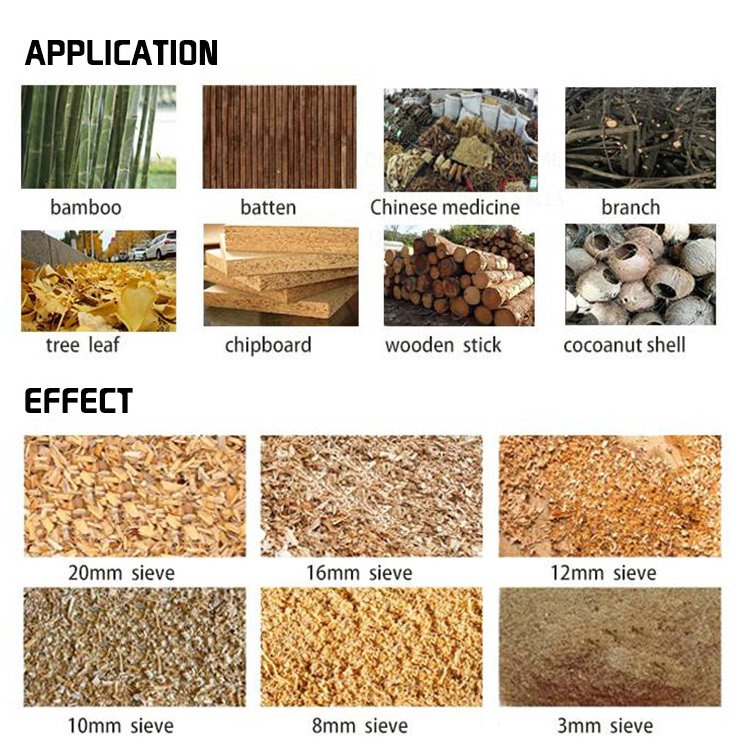

2.APPLICATION & EFFECT

Branch pulverizers are widly applicable. They can crush both dry branches and fresh wet branches quickly into small pieces. Moreover, the branch crusher has no requirement on material size, and leaves, branches, trunks and even whole trees can be crushed with it. Branch pulverizers are suitable for gardens, orchards, forestry, highway tree maintenance, parks, golf courses and other fields.

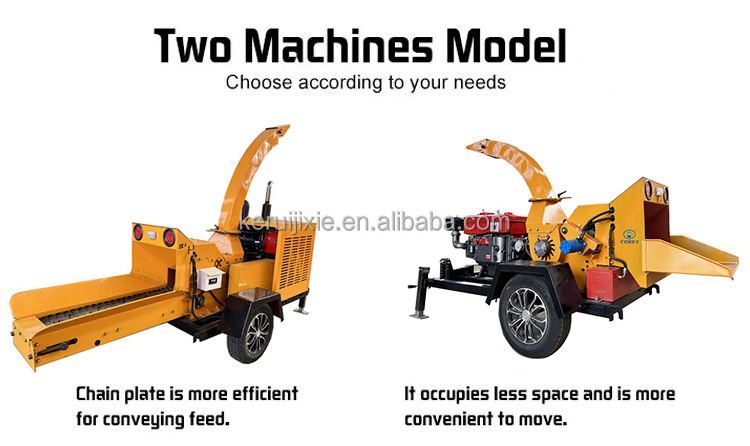

3.VARIOUS MODELS ARE AT YOUR DISPOSAL

4.PRODUCT ADVANTAGE

1.The wood chipper is equipped with the hydraulic feeding roller, improving the working efficiency.

2. A powerful feeding system is combined with the production line.

3. Blades are made of specialized alloy so they are much more durable.

4. Blades that are worn out can be repaired.

5. Famous cabinet controller and motor are used.

6. Fully automatic operation saves both cost and labor.

5.

PRODUCT DETAILS

pIt can easily cut 6" logs with a throughput of 1000 kg/hr

Mobile, convenient, fast, small footprint, wide range of uses.

Powered by a fourcylindersupercharged diesel engine, full of power

6.TECHNICAL PARAMETER

|

Model

|

380

|

|

|

580

|

780

|

|

980

|

||||||

|

Hourly production capacity

|

1-2t

|

|

|

3-4t

|

3-5t

|

|

3-5t

|

||||||

|

Weight

|

≤800kg

|

|

|

2000kg

|

3000kg

|

|

≤3500kg

|

||||||

|

Power

|

32 HP

|

25 HP

|

50 HP

|

80 HP

|

80 HP (60KW)

|

102HP(75KW)

|

154HP(113KW)

|

||||||

|

Feed

|

Tray hydraulic forced feeding

|

|

|

|

|

|

|

||||||

|

Feed port length

|

1060mm

|

|

|

1300mm

|

2300mm

|

|

2500mm

|

||||||

|

Outside diameter of feed port

|

650mm ×440mm

|

|

|

1000mm ×600mm

|

1320mm×690mm

|

|

1500mm×940mm

|

||||||

|

Inside diameter of feed port

|

300mm × 200mm

|

|

|

400mm × 320mm

|

470mm×440mm

|

|

530mm×590mm

|

||||||

|

Discharge

|

Discharge caliber type 360 degree rotation

|

|

|

Discharge caliber type 360 degree rotation

|

/

|

|

|

||||||

|

Height of discharge port

|

1700mm

|

|

|

2400mm

|

/

|

|

|

||||||

|

Applicable material size

|

Fresh branch diameter≤100mm

|

|

|

Fresh branch diameter≤150mm

|

/

|

|

|

||||||

|

Cutter roll diameter

|

300mm

|

|

|

370mm

|

540mm

|

|

670mm

|

||||||

|

Number of cutters

|

3 double-edged cutters (can be reversed twice)

|

|

|

4 double-edged cutters (can be reversed twice)

|

/

|

|

|

||||||

|

Number of bottom cutters

|

1 (can be reversed four times)

|

|

|

1 (can be reversed four times)

|

/

|

|

|

||||||

|

Bearing

|

Famous brand, easy to maintain and configure

|

|

|

Famous brand, easy to maintain and configure

|

Brand bearing, easy to maintain and configure

|

|

|

||||||

|

Underframe, chassis type

|

Integrated

|

|

|

Integrated

|

Integrated

|

|

|

||||||

|

Moving method

|

Towed to move

|

|

|

Towed to move

|

Towed to move

|

|

|

||||||

|

Wheel size

|

165/70R13

|

|

|

165/70R13

|

600-16

|

|

650-16

|

||||||

|

Hydraulic oil tank

|

680mm × 240mm × 200

|

|

|

900mm×200mm×200mm

|

600mm×260mm×430mm

|

|

710mm×260mm×460mm

|

||||||

|

Starting system

|

Electric start, with 12V battery.

|

|

|

Electric start, with 12V battery.

|

Electric start, equipped with 24V battery.

|

|

|

||||||

|

Outline dimension

|

2300mm × 1300mm×1700m

|

|

|

2800mm×1600mm×2400mm

|

4600mm×1800mm×2900mm

|

|

4600mm×2000mm×3500mm

|

||||||

7.RELATED PRODUCT RECOMMENDATION

Corey Machinery Equipment Co., Ltd. pays attention to the introduction of advanced production technology at home and abroad. We sell notonly single machines, but also complete production lines. Since its establishment, we have always paid attention to research and developm-ent of equipment quality and performance.Whether it is an independent solution or a complete system, you can customize our machines .

1.FACTORY DISOLAY & PROCESS TECHNOLOGY

We not only sell single machines, but also sell complete production lines. We produce industrial shredders for material recycling. We can provide all kinds of garbage shredders: waste tires, big garbage, urban solid garbage, wood, metal, paper and cardboard, rubber, plastic and so on.

2.OUR CERTIFICATE

Business integration enterprise,and the products have obtained many patents and CE certification.

3.CASE PRESENSATION

Corey enjoys a high reputation in many countries and regions around the world, and has won the trust of many

well-known enterprises at home and abroad with its practical products and perfect after-sales service.

4.OUR SERVICES

1. Pre-sales:

Provide fitted solution and offer to customers, is able to adjust the layout of complete line to fit customers’working area, also provide technical support 24 hours service online.

2. After sales:

Corey skilled technicians are experienced at oversea installation, therefore they are available to assist with onsite installation, commissioning & training on request.

3. Wearing parts support

Corey has widely built extensive cooperation with wearing parts partner manufacturers more than 14years, has ability to continuously provide wearing parts and after-sale service to global market.

6.CUSTOMER FEEDBACK

FAQ

Q1: Can you customize this machine for me according to my needs?

Of course, it is our pleasure to solve problems for every customer. You can also tell us your specific needs. For example, raw material type, raw material diameter, hourly output, finished product diameter, etc. We can customize the solution for you.

Q2: What about the machine installation?

For a single machine or a simple production line, we will provide you with basic drawings, installation instructions or pictures or videos of successfully installed machines; For large machines and complex production lines, we can send engineers to guide the installation when necessary.

Q3: What about spare parts?

We provide some free spare parts, such as belts, gaskets and other small parts, blades, knives, shafts and other important worn parts. We suggest that customers buy some with the machine to save transportation costs, and we have enough spare parts in stock.

Q4: What should we do if there is something wrong with the operation of the machine after we buy it?

Corey has dedicated after-sales service personnel. If customers outside China have problems working on machines, please send us pictures or videos, and we will provide you with solutions within 24 hours.

Q5: Can we visit your factory and test the machine?

We warmly welcome you to visit our factory at any time. We are glad to test our machines with your raw materials.

Hot Searches