- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

160*130*125CM

-

Weight:

-

360 kg

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

Final product:

-

Pellet Food

-

Pellet size:

-

1.5mm-12mm

-

Material:

-

Durable Carbon Steel

-

Application:

-

Pet Food

-

Product name:

-

Floating Fish Feed Extruder

-

Usage:

-

Fish Feed Expanded

-

Function:

-

Aniaml Fish Feed Puffed Pellet Machine

-

Keywords:

-

Floating Fish Food Making Extruder Machine

-

Suit for:

-

Pet Food Production

Quick Details

-

Max. Capacity:

-

120-160kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DURABLE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

160*130*125CM

-

Weight:

-

360 kg

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

Final product:

-

Pellet Food

-

Pellet size:

-

1.5mm-12mm

-

Material:

-

Durable Carbon Steel

-

Application:

-

Pet Food

-

Product name:

-

Floating Fish Feed Extruder

-

Usage:

-

Fish Feed Expanded

-

Function:

-

Aniaml Fish Feed Puffed Pellet Machine

-

Keywords:

-

Floating Fish Food Making Extruder Machine

-

Suit for:

-

Pet Food Production

◇This machine is pellet feed extruding equipment. Fish food, cat food, dog food and other pet feed extruders. It can produce a variety of flower shapes, and molds can be customized according to requirements.

◇

The product outlet is equipped with a frequency conversion speed regulating rotary cutting device, which can adjust the blade rotation speed arbitrarily to control the cutting speed and length.

◇

This equipment uses corn, soybean (bean cake) animal scraps as raw materials, and can be directly added into the machine to produce different particles with novel shape, unique taste, rich nutrition and delicate tissue. It is suitable for dogs, cats, fish, birds, rabbits, shrimps, wait.

◇

If the raw material is powder, it can be directly made into granules;If the raw materials are particle size, firstly, we need to crush them into powder less than 3mm.

◇There are also some requirements for raw material moisture, if it is less than 30%, it is better.

Limited time offer: order now and get 5 moulds for free!

The feed extruder can produce a variety of feed pellets: pet feed, aquatic feed, etc. such as: cat food, dog food, fish feed, various fishing baits, nesting feed, floating water feed, submerged water feed, 1-20mm pellets

.

It is suitable for farmers, small and medium-sized feed factories and research institutions. The extruded feed pellets produced by this machine are neat and smooth.

|

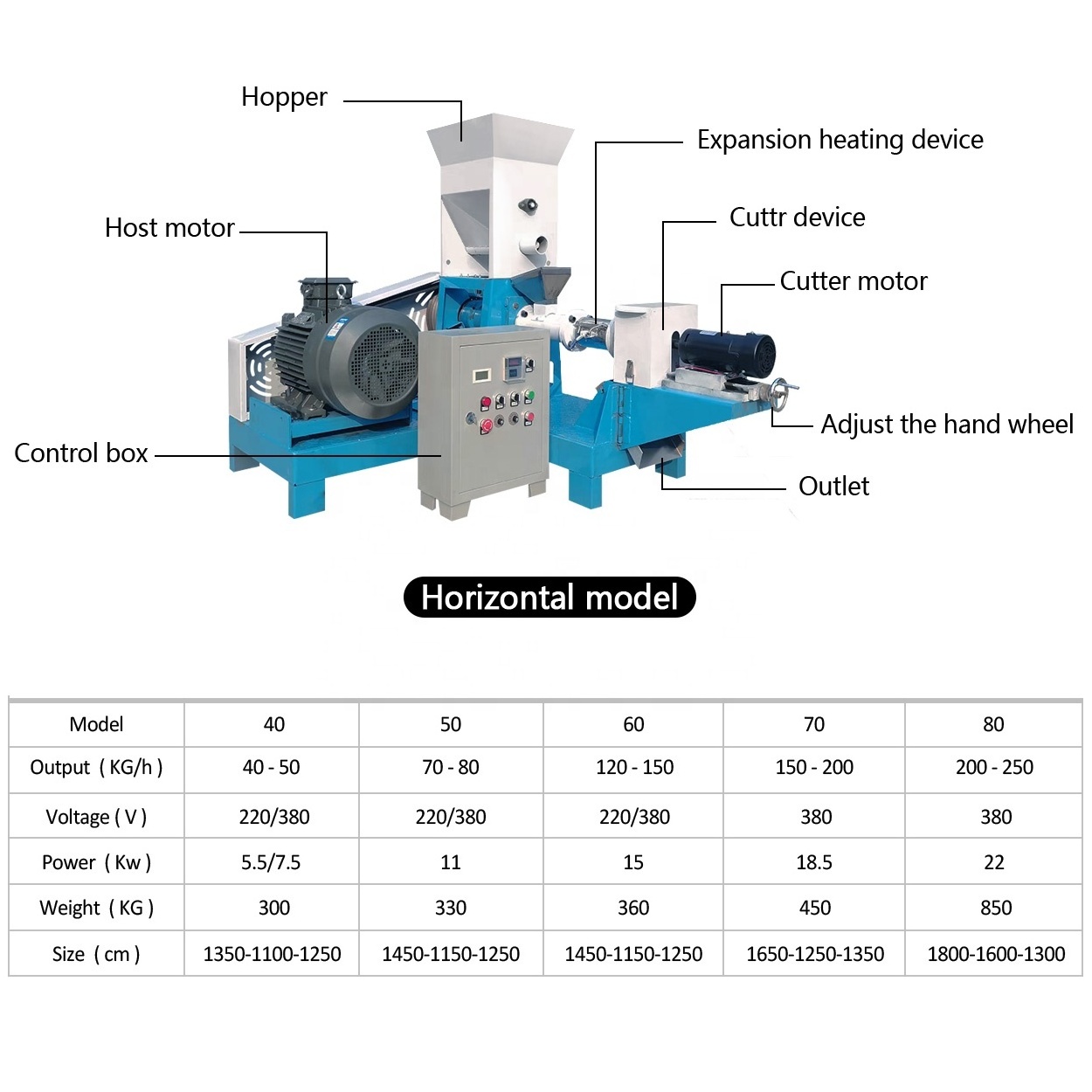

model

|

40

|

60

|

70

|

80

|

|

power

|

5.5KW

|

15KW

|

18.5KW

|

22KW

|

|

Yield(kg/h)

|

40-50

|

120-150

|

150-200

|

200-250

|

|

weight

|

300KG

|

360KG

|

450KG

|

850KG

|

|

size(mm)

|

1350-1100-1250

|

1450-1150-1250

|

1650-1250-1350

|

1800-1600-1300

|

Pure copper motor

The whole machine adopts international standard pure copper motor, which runs smoothly and has low failure rate.

Heated variable speed cutting

Spiral design, rapid heating and efficient work, more uniform output, and the length of feed particles can be adjusted arbitrarily.

Expansion heating device

Equipped with multiple sets of heating plates, the temperature rises rapidly and the puffing effect is good

Cutter device

Adjust the blade rotation speed, you can control the speed and length of the cut.

Automatic feeding port

The speed can be adjusted arbitrarily, the operation is more convenient, and the feeding is uniform to prevent the machine from jamming.

control Panel

Control the overall operation of electrical components, durable, split control electric box, good stability

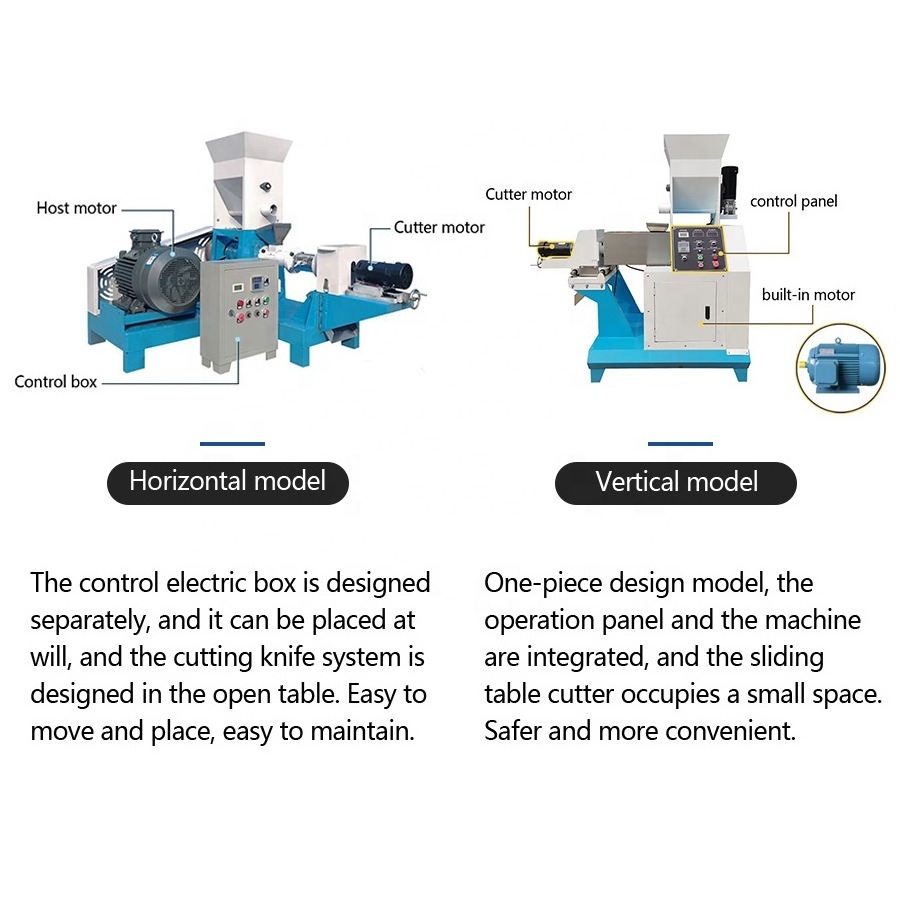

Horizontal model

The control electric box is designed separately, and it can be placed at will, and the cutting knife system is designed in the open table. Easy to move and place, easy to maintain.

Vertical model

One-piece design model, the operation panel and the machine are integrated, and the sliding table cutter occupies a small space. Safer and more convenient.

|

Model

|

45

|

65

|

75

|

85

|

|

Power

|

5.5KW

|

15KW

|

18KW

|

22KW

|

|

Yield(kg/h)

|

40-50

|

100-150

|

250

|

350

|

|

Weight

|

350KG

|

500KG

|

750KG

|

850KG

|

|

Size(mm)

|

1800*810*1080

|

1700*970*1240

|

1700*970*1240

|

1850*1070*1400

|

①mixing mixer→②feed extruder→③stainless steel dryer→④star anise seasoning machine

1. Put the well-proportioned raw materials and the well-proportioned water into the mixing mixer, and stir quickly and evenly.

2. Put the mixed raw materials into the feeding hopper of the extruder, open the feeding device, temperature control, and cutter for puffing production.

3. Put the container under the discharge port of the extruder, and use the container to hold the semi-finished granules.

4. Put the semi-finished granules in the container into the hot air dryer, turn on the dryer, and dry it evenly.

5. The dried semi-finished granules are put into the star anise seasoning machine, and the animal fat with a good ratio is added for tumbling seasoning.

6. After seasoning, pour out the granules, which is the finished pet food.

mixing mixer

Pour the raw materials into the mixer for stirring, and stir for 3-5 minutes, increase the stirring equipment, stir evenly, with high efficiency, and pour it into the automatic feeding machine.

Feeding hoist

Made of thick stainless steel, equipped with a copper core motor, the screw auger lifts the feeding, the feeding is stable, and the raw materials are poured into the extruder.

Extruder host

Raw materials are poured into the puffing machine for puffing. The main machine of the puffing machine supports customization, puffing and forming semi-finished products, which are transported into the drying box by wind.

Automatic air delivery system

Made of stainless steel, automatic air delivery system, stable air delivery, high-power motor is selected to drive the fan to feed materials.

Multi-layer drying box

Thicken the shell, make a multi-layer dryer to ensure uniform drying, install heating tubes on each layer for drying, and multi-layer drying, the effect is good.

Air blower

Send the semi-finished product into the drying box for drying. The air blower is made of high-quality 304 food material, equipped with an enlarged fan and a high-power motor, and the air flow is stable.

Fuel injector

Timing and quantitative fuel injection machine, automatic fuel injection, uniform fuel injection, good fuel injection effect, convenient control.

Drum seasoning machine

Drum seasoning machine made of food material, lengthened design, even seasoning, stable turning, even turning speed, good seasoning effect.

The packaging will be sandblasted and sprayed with high-quality paint, pp bubble product packaging.

Load the container, in order to reduce the transportation cost as much as possible, we will pack the machine with a moisture-proof film in advance and put it in an impact-resistant wooden box.

The transportation can be by sea or land, provide cargo information at any time, and we will remind you before the ship arrives.

Packaging and Delivery We provide suitable packaging solutions according to the order quantity and quantity of goods to ensure no damage during transportation.

1. How about the quality? easy to use? How is the effect?

Improve the utilization rate of feed:

Since the fish feed extruder can expand the feed under high temperature and high pressure, the expanded feed is easily digested and absorbed by the fish, which can improve the feed utilization rate of the fish.

Improve feed quality:

the extruded feed particles are uniform in size and moderate in density, which can reduce feed waste and pollution and improve feed quality

Improve production efficiency:

The fish feed extruder can realize automatic production, which greatly improves production efficiency and reduces labor costs.

Energy saving:

The fish feed extruder adopts advanced heating and extruding technology, which can save energy and reduce emissions, and meet environmental protection requirements.

Strong adaptability:

the fish feed extruder can adapt to the production of feeds of different types, shapes and tastes, and can meet various breeding needs.

2

.

I don’t know what materials to use to process feed?

Use corn, soybean (bean cake) animal scraps as raw materials, and directly add them into the machine to produce different granules with novel shape, unique taste, rich nutrition and fine texture, suitable for dogs, cats, fish, birds, rabbits, shrimps, Feeds with different tastes for dogs, cats, minks, foxes, etc.

3. What is the scope of application?

It is suitable for professional farmers, small and medium-sized feed mills and research institutions. In the case of the same feed formula, the cost of self-made extruded feed is 60%-80% lower than the market price; the extruded feed pellets produced by this machine are neat and smooth, and the floating water surface does not sink for more than 12 hours, does not pollute the water source, and is sterilized Reduce fish disease, the size, length and shape of puffed particles can be adjusted at will.

4. Is it easy to operate? Is the quality guaranteed?

The machine is easy to operate, has low noise, and can be started with one button, which is convenient and fast. The motor guarantees pure copper wire, if you have any questions, please contact us directly. 24-hour online guidance, professional and technical personnel to answer questions, and considerate after-sales service.

Hot Searches