- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

1900mm*2300mm*2400mm

-

Weight (KG):

-

3000

-

Application:

-

Dry the powder

-

Max temperature:

-

250C=450F

-

Heating Time:

-

25-45minutes

-

Air Circulation:

-

closed

-

Burner capacity:

-

100,000kcal

-

Insulation:

-

Rock wool

-

Size:

-

Customized

-

Weight:

-

3000KG

-

Lead time:

-

10 workdays

Quick Details

-

Machine Type:

-

Powder coating curing oven, Drying Oven, Curing oven

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Mingderixin

-

Voltage:

-

Customized

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

1900mm*2300mm*2400mm

-

Weight (KG):

-

3000

-

Application:

-

Dry the powder

-

Max temperature:

-

250C=450F

-

Heating Time:

-

25-45minutes

-

Air Circulation:

-

closed

-

Burner capacity:

-

100,000kcal

-

Insulation:

-

Rock wool

-

Size:

-

Customized

-

Weight:

-

3000KG

-

Lead time:

-

10 workdays

Automatic Powder Coating Line for Spray Painting Metal Furniture With Diesel Oven

|

Specifications |

|

|

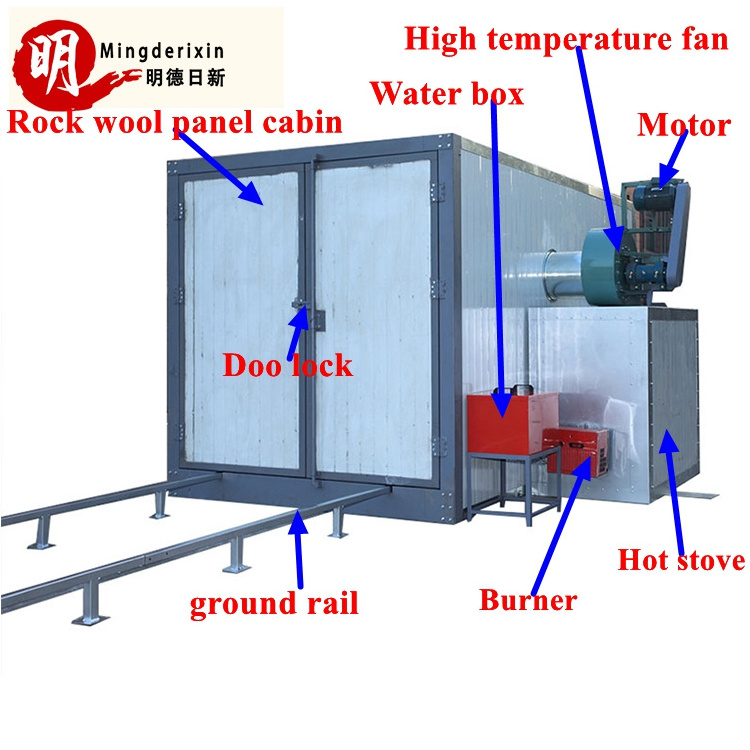

Chamber panel |

Assembled insulation chamber. 100 mm thickness Rockwool panel; 120kg/m 3 . Outside is colorful steel, 0.476mm; inner surface is galvanized steel, 0.476m. High quality rock wool board, insulation and fireproof, easy to install. Two h inge doors, and door leaf is also made of 100mm thick rock wool panel, surrounded by 1.5mm galvanized sheet, and is firmly insulated. |

|

Heating system |

Italy Diesel Burner Heat chamber and Heat exchange tubes are made of 304 and 316 stainless steel. With rock wool insulation . |

|

Circulation system |

With a high temperature centrifugal fan With cooling system Cooling circulation fan bearing part . The fan impeller is made by stainless steel. The fan bearing protection method is liquid circulation cooling protection. Independently adjustable hot air ducts are arranged inside the chamber to make the temperature in the curing furnace uniform. The air duct is made by punching and bending with a 0.8mm galvanized sheet. |

|

Guide Rail |

One side equip ground rail used for workpiece entry and exit. |

|

Optional |

T ransfer trolley |

|

Control system |

Microcomputer control, dual display digital temperature controller, hot air temperature and oven temperature are automatically controlled. Fan control, heating control, temperature control, indicator lights for various items, and emergency stop. Safety device , one set of explosion-proof relief valve, when the pressure inside the curing furnace increases, it will automatically open and discharge the excess air. |

Models

|

No. |

Model |

Inside size ( L*W*H)mm |

Outside size ( L*W*H)mm |

|

1 |

MD-D19 |

1900*2100*2000 |

2100*2300*2400 |

|

2 |

MD-D028 |

2650*2100*2000 |

2850*2300*2400 |

|

3 |

MD-D038 |

3600*2100*2000 |

3800*2300*2400 |

|

4 |

MD-D048 |

4550*2100*2000 |

4750*2300*2400 |

|

5 |

MD-D057 |

5500*2100*2000 |

5700*2300*2400 |

|

6 |

MD-D066 |

6450*2100*2000 |

6650*2300*2400 |

|

Remarks: Choose your favorite size ,and let me know . |

|||

Advantage

1.304 stainless steel fan impeller,

2. The fan bearing is water-cooled,

3. The burner is the road of Leah

4. The control cabinet is touch screen + PLC, the furnace temperature, hot air temperature, and holding time are automatically controlled (the temperature is only started)

5. The insulation layer of the heating system itself is aluminum silicate, not rock wool.

6. Heating system The hot air chamber is stainless steel, not galvanized sheet

7. Curing oven body insulation is 100kg bulk density of high quality rock wool, continuous working skin is not hot

8. With heavy rail (inside and outside rail)

9. It is used as a high temperature resistant wheel for workpiece trailers.

Related Products

Factory