- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jet-ink

-

Model Number:

-

KYH-C-6001

-

Product name:

-

Edible Ink Refill Cartridges

-

MOQ:

-

100 sets Edible Ink Refill Cartridges

-

Usage:

-

Inkjet Food Printing

-

Packing:

-

100ml*4/set, 100ml/bottle

-

Colors:

-

Cyan Magenta Yellow Black (brown)

-

ingredients:

-

Raw materials extracted from plants.

-

Storage:

-

Sealed, keep in the cool and dry conditions

-

suitable machine:

-

// inkjet machine

-

Feature:

-

safe & health

-

Certificate:

-

Intertek

Quick Details

-

Type:

-

Water Based Ink

-

Printing Type:

-

Digital printing

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Jet-ink

-

Model Number:

-

KYH-C-6001

-

Product name:

-

Edible Ink Refill Cartridges

-

MOQ:

-

100 sets Edible Ink Refill Cartridges

-

Usage:

-

Inkjet Food Printing

-

Packing:

-

100ml*4/set, 100ml/bottle

-

Colors:

-

Cyan Magenta Yellow Black (brown)

-

ingredients:

-

Raw materials extracted from plants.

-

Storage:

-

Sealed, keep in the cool and dry conditions

-

suitable machine:

-

// inkjet machine

-

Feature:

-

safe & health

-

Certificate:

-

Intertek

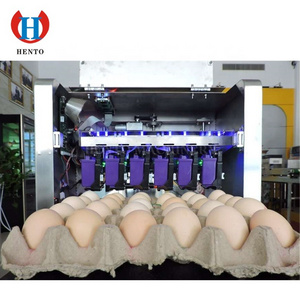

Hot Sell Candy Edible Ink Printer Edible Ink Refill Cartridges Edible Sugar Paper Edible Ink Cake Printing |

| The edible inkjet ink which satisfies the requirement of quickly printing of the food production line ,is clear ,smooth,safe and healthy,and is widely used in pastry ,ice cream,candy ,cookie,ect.The printer provides customized color schemes service to food, and enables acceleration for food industry. |

Product Description

Details:

| Sensory requirement | Viscous liquid, color uniformity, no agglomerate, mildew, no visible foreign material, no peculiar smell |

| Arsenic(AS,mg/kg) | ≤2.0 |

| Plumbum(Pb,mg/kg) | ≤2.0 |

| Microbial limit | Bacteria amounts(cfu/g) ≤1000 |

| Mould and yeasts (cfu/g) ≤100 | |

| Escherichia coli Not be detected | |

| Salmonella Not be detected | |

| Aberration | ≤2.0 |

| PH | 5.0~10.0 |

| Fineness(μm) | ≤1.0 |

| Viscosity(mPa.s) | 2.0~20.0 |

| Surface Tension(Mn/m) | 30~45 |

| Conductivity(μS/cm) | <10000 |

Operation Attention

1. Shake well before use.

2. The period of validity is 12 months.

3. In order to avoid the influence caused by mixture of different oil , the equipment should be cleaned

before using.

4. The equipment should be cleaned if it was turned off for a long time.

Application

Hot Searches