- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MEIQI

-

Model Number:

-

MQ-004

-

Use:

-

Grinding

-

Product name:

-

Best -325mesh boron carbide powder b4c

-

keyword:

-

boron carbide B4C

-

Application:

-

abrasive material

-

Melting Poing:

-

2450 degree

-

Mohs Hardness:

-

9.3

-

MSDS:

-

External MSDS

-

Moleclar Formula:

-

B4C

-

Solubility in water:

-

Insoluble

-

Molar mass:

-

55.255 g/mol

-

Boiling Point:

-

3500 degree

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

F60-F1500

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MEIQI

-

Model Number:

-

MQ-004

-

Use:

-

Grinding

-

Product name:

-

Best -325mesh boron carbide powder b4c

-

keyword:

-

boron carbide B4C

-

Application:

-

abrasive material

-

Melting Poing:

-

2450 degree

-

Mohs Hardness:

-

9.3

-

MSDS:

-

External MSDS

-

Moleclar Formula:

-

B4C

-

Solubility in water:

-

Insoluble

-

Molar mass:

-

55.255 g/mol

-

Boiling Point:

-

3500 degree

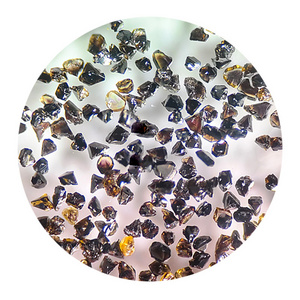

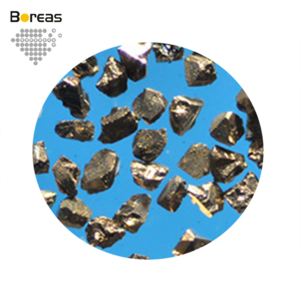

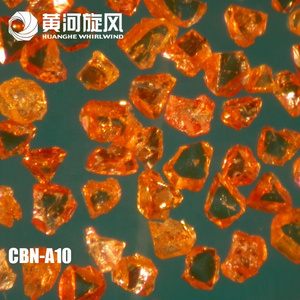

Boron carbide

Boron carbide is hard black with glossy crystals. Hardness is lower than industrial diamond, but higher than silicon carbide. It is less vulnerable than most pottery. It has a large thermal neutron capture cross section. Strong resistance to chemistry. The erosion of hydrogen fluoride and nitric acid. Soluble in molten base, insoluble in water and acid.

|

Grit Size

|

Size(μm)

|

Chemical Composition

|

|

|

|

|||

|

|

|

B%

|

C%

|

Fe2O3%

|

BC%

|

|||

|

60#

|

315-215

|

78-81

|

17-22

|

0.2-0.4

|

97-99

|

|||

|

80#

|

200-160

|

|

|

|

|

|||

|

100#

|

160-125

|

|

|

|

|

|||

|

120#

|

125-100

|

78-80

|

17-22

|

0.2-0.4

|

96-98

|

|||

|

150#

|

100-80

|

|

|

|

|

|||

|

180#

|

80-63

|

|

|

|

|

|||

|

240#

|

60-50

|

77-80

|

17-22

|

0.3-0.5

|

96-97

|

|||

|

280#

|

50-40

|

|

|

|

|

|||

|

320#

|

40-28

|

|

|

|

|

|||

|

W40(360#)

|

35-28

|

76-79

|

17-21

|

0.3-0.6

|

95-97

|

|||

|

W28(400#)

|

28-20

|

|

|

|

|

|||

|

W20(500#)

|

20-14

|

75-79

|

17-21

|

0.4-0.8

|

94-96

|

|||

|

W14(600#)

|

14-10

|

|

|

|

|

|||

|

W10(800#)

|

10-7

|

74-78

|

17-21

|

0.4-0.9

|

92-94

|

|||

|

W7(1000#)

|

7-5

|

|

|

|

|

|||

|

W5(1200#)

|

5-3.5

|

74-78

|

17-21

|

0.5-0.9

|

90-93

|

|||

|

W3.5(1500#)

|

3.5-2.5

|

|

|

|

|

|||

|

-325#

|

<45

|

74-79

|

17-22

|

<0.4

|

92-97

|

|||

|

0-44μm

|

<45

|

|

|

|

|

|||

|

-200#

|

<90

|

74-80

|

17-22

|

<0.3

|

94-97

|

|||

|

-100#

|

<150

|

|

|

|

|

|||

|

-25μm

|

<25

|

74-79

|

17-21

|

<0.3

|

92-96

|

|||

|

-10μm

|

<10

|

74-78

|

17-21

|

<0.3

|

91-95

|

|||

|

60#-150#

|

250-75

|

77-81

|

17-22

|

<0.3

|

95-98

|

|||

|

40#-120#

|

315-106

|

|

|

|

|

|||

|

30#-60#

|

355-250

|

|

|

|

|

|||

|

Boron carbide

|

355-250

|

92-80

|

17-23

|

<0.3

|

90-99

|

|||

Application:

1. High-grade particle grinding material;

2. Make chemical ceramic,glass ,or nozzle;

3. Nuclear reactor and shielding material;

4. Produce bullet proof armor;

5. Improve the service lift of mechanical parts;

6. As additive filler for boron chemical materials;

7. Essential filler for refractory materials.