- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Client local standard

-

Dimension(L*W*H):

-

Depend on model

-

Weight:

-

600 KG

-

Product name:

-

Vibration screen

-

Function:

-

Screening\separation\sieving

-

Layer:

-

Custom made

-

Capacity:

-

Depend on model

-

Material:

-

Carbon Steel

-

Sieve size:

-

5-80mm

-

Max feeding size:

-

<200mm

-

Angle:

-

15-25 degree

-

Installation:

-

Engineer Guide

-

Local Service Location:

-

None

Quick Details

-

Type:

-

Standard

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JINCHUAN

-

Voltage:

-

Client local standard

-

Dimension(L*W*H):

-

Depend on model

-

Weight:

-

600 KG

-

Product name:

-

Vibration screen

-

Function:

-

Screening\separation\sieving

-

Layer:

-

Custom made

-

Capacity:

-

Depend on model

-

Material:

-

Carbon Steel

-

Sieve size:

-

5-80mm

-

Max feeding size:

-

<200mm

-

Angle:

-

15-25 degree

-

Installation:

-

Engineer Guide

-

Local Service Location:

-

None

Product Description

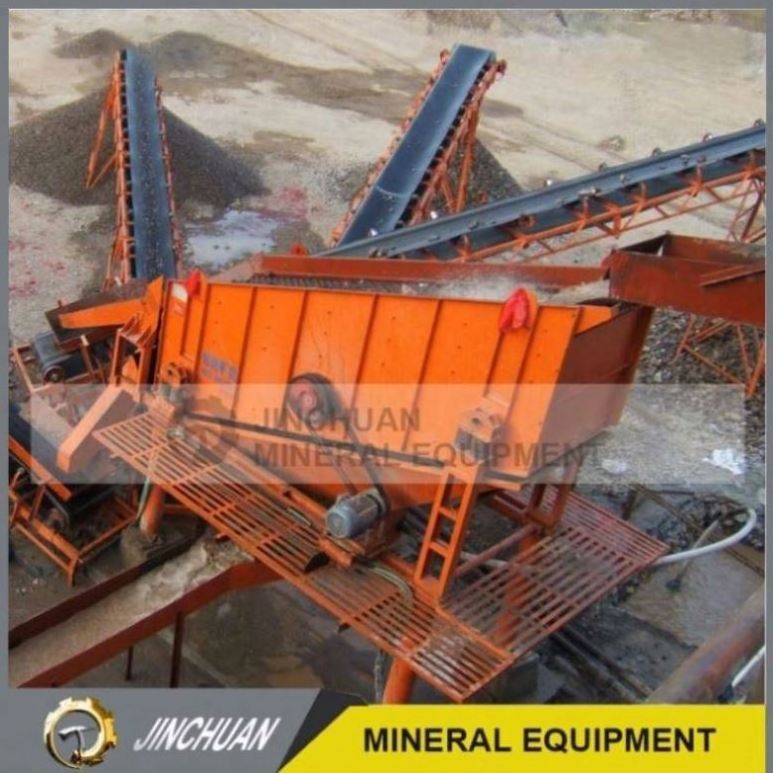

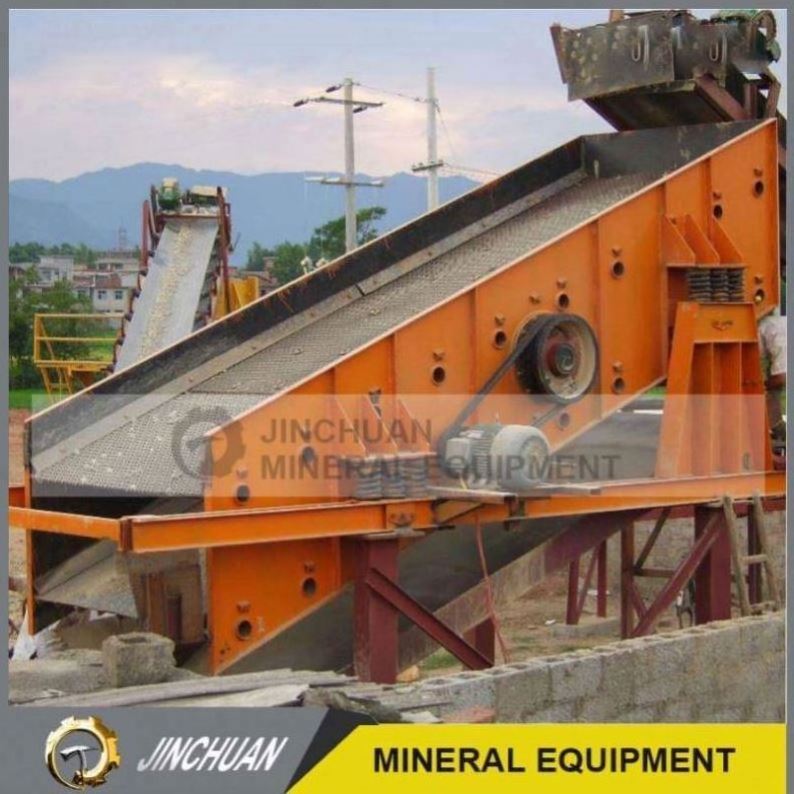

The vibrating screen is a new screening equipment, the vibration trajectory is an ellispse, is designed specifically for material stone screening in quarry, but also used for coal preparation, mineral processing, building materials, electricity and chemical departments for production classification.

Main Features of vibrating screen

1.high efficiency, low energy consumption;

2.simple structure, convenient maintenance;

3.fully closed structure without dust pollution;

4.Stable working station and smooth operation;

5.High utilization rate of screen, large unit area, not easy to block, but easy replacement of screen.

6.High-precision screening reach to 96% or above, large processing capacity, etc.

Working principle

The motor makes the exciter swing rotate speedily through the tire coupling. The continuous forced circular motions of sieve box were achieved through the powerful centrifugal force. Under the influence of sieve box, the materiel are tossed forward successively on the mesh. they were classified as thrown up, and the particles smaller than the mesh size were sieved out when they are falling, so that the classification of material could be achieved.

Vibrating screens operate on an inclined surface. A deck moves in a circle. It operates with a continuous feed rather than in batches, leading to much greater output. The incline allows the feed to move through the device. A vibrating screen is a screening machine employed in processes involving particle separation. In particle processes screening refers to separation of larger from smaller particles in a given feed, using only the materials' physical properties.

Vibrating screen uses electric exciter as vibrating source, the material will be thrown around the screen, at the same time doing forward sports, in order to achieve the screening purpose. Material from the feeder evenly enters into the machine's feeding inlet, with multi-layer sieves to produce various of products and unqualified products on the screen or under the screen, then discharging from the outlet respectively. It can be used in the automatic production line.

Application

It is widely used in plastics, abrasive, chemical, pharmaceutical, building materials

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

100% Response Rate

100% Response Rate

100% Response Rate