<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OK Machinery

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

2500 KG

-

Product name:

-

can filling machine

-

Capacity:

-

2000-30000bph

-

Name:

-

PET metal soda/beer aerosol can filling machine

-

Function:

-

can Washing Filling Capping

-

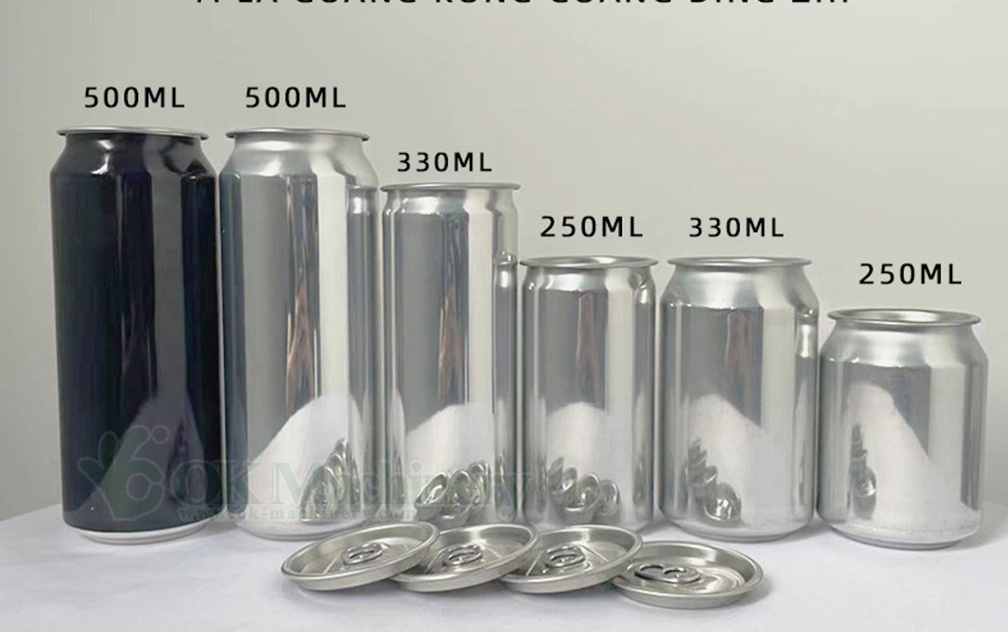

Filling range:

-

200-2000ml

-

Model:

-

can Filling Equipment

-

Bottle type:

-

Round Bottle

-

Filling material:

-

Flowing Liquid

-

Material:

-

Stainless Steel 304

Quick Details

-

Machinery Capacity:

-

4000BPH, 12000BPH, 20000BPH, 16000BPH, 1000BPH

-

Packaging Material:

-

Wood, PET metal soda/beer aerosol can filling machine

-

Filling Material:

-

Beer, Juice

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OK Machinery

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

2500 KG

-

Product name:

-

can filling machine

-

Capacity:

-

2000-30000bph

-

Name:

-

PET metal soda/beer aerosol can filling machine

-

Function:

-

can Washing Filling Capping

-

Filling range:

-

200-2000ml

-

Model:

-

can Filling Equipment

-

Bottle type:

-

Round Bottle

-

Filling material:

-

Flowing Liquid

-

Material:

-

Stainless Steel 304

Product Description

whole tin line price beverage plant automatic aluminium beer can filling machine

1.It is used in the can filling and seaming for water. The filling and seaming are designed in one body. The power of filling

system is provide by the seaming system to assure the synchronization and harmony.

2.It is the latest equipment made on the basis of advanced technology of drink can filling and seaming .

3.Adopt the advanced mechanism, electronic components and pneumatic control technology, apply isobaric pressure filling theory, the filling speed is fast, the liquid level is stable with loss. Seaming quality is good, the machine run smoothly, appearance is beautiful, operation and maintenance is convenient, the production speed apply frequency conversion, and long-distance control system can be collocated according to the request of client.

4.As the can is easy to get deformed, soft treatment is needed in the transferring process. The conveying system regulates the transferring speed according to the each machine’s working condition to assure no bottle falling or crashing occurs.

system is provide by the seaming system to assure the synchronization and harmony.

2.It is the latest equipment made on the basis of advanced technology of drink can filling and seaming .

3.Adopt the advanced mechanism, electronic components and pneumatic control technology, apply isobaric pressure filling theory, the filling speed is fast, the liquid level is stable with loss. Seaming quality is good, the machine run smoothly, appearance is beautiful, operation and maintenance is convenient, the production speed apply frequency conversion, and long-distance control system can be collocated according to the request of client.

4.As the can is easy to get deformed, soft treatment is needed in the transferring process. The conveying system regulates the transferring speed according to the each machine’s working condition to assure no bottle falling or crashing occurs.

Specification

whole tin line price beverage plant automatic aluminium beer can filling machine The machine is advanced filling and

capping equipment, it’s designed on the basis of absorbing domestic and foreign advanced technology. It is mainly used in filling and capping carbonated beverages like soft drinks, cola, sparkling wine, etc. It has suchadvantages as advanced construction, stable working, convenient operation, and repair & maintenance, transducer control as well as high production efficiency. It is the ideal equipment for mid-scale & small-scale beverage factory.

capping equipment, it’s designed on the basis of absorbing domestic and foreign advanced technology. It is mainly used in filling and capping carbonated beverages like soft drinks, cola, sparkling wine, etc. It has suchadvantages as advanced construction, stable working, convenient operation, and repair & maintenance, transducer control as well as high production efficiency. It is the ideal equipment for mid-scale & small-scale beverage factory.

|

Model

|

GF18-6

|

GF24-6

|

GF32-6

|

GF40-8

|

|

Capacity

|

6000-8000cans/hour

|

8000-10000 CPH

|

10000-12000 CPH

|

15000-18000 CPH

|

|

Can Volume

|

200ml-1000ml

|

200ml-1000ml

|

200ml-1000ml

|

200ml-1000ml

|

|

Can diameater

|

50-70mm

|

50-70mm

|

50-70mm

|

50-70mm

|

|

Bottle high

|

120-170mm

|

120-170mm

|

120-170mm

|

120-170mm

|

|

Machine power

|

3.5KW

|

5.5KW

|

7.5KW

|

9.5KW

|

|

Machine size

|

175x120x195CM

|

305x175x220CM

|

340X195X220CM

|

350x235x225CM

|

Product details

Filling part

Capping part

<1> Place and can sealing system, electromagnetic capping heads, with burden discharge function,make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction <3> No cans no capping

<4> Automatic stop when lack of cans

<2> All 304/316 stainless steel construction <3> No cans no capping

<4> Automatic stop when lack of cans

Related machine

Water treatment system

RO( Reverse Osmosis)

hereinafter referred to as RO, principle is the raw water under high pressure through the Reverse Osmosis membrane, the solvent diffus from high to low concentration in the water so as to achieve the purpose of the separation, purification, concentration, it can not only remove ion range of impurities, also can remove organic pollutants, microorganisms, viruses, and pyrogen ete. , using other methods to remove impurities

Can unloading stamping machine Can Depalletizer

1. Replace manual emptying and traditional emptying machine, which can save a lot of labor and improve production capacity.

1. Replace manual emptying and traditional emptying machine, which can save a lot of labor and improve production capacity.

2.Adopt programmable computer control system to improve the accuracy and ease of operation of mechanical actions.

3. The pallet lifting platform self-locking lifting and lifting, the pallet stacking machine adopts cylinder lifting and lifting, the movement is stable.

4. Continuous movement or single cycle movement can be selected to push the can, with high operation adaptability.

5.Suitable for emptying tin cans of various sizes and aluminum cans

Sleeve shrinking label machine

Suitable for all kinds of bottle of juice, tea drinks, dairy products, pure water, condiments, beer, food and beverage industry such as sports drinks, not only of label position is high, and the more prominent bottle perfect contracting bottle type. Bottle type has More flexible choicet to set of round bottle, square bottle, ellipse bottle, ete. , Wide applicable scope: is suitable for food, beverage, cleaning supplies, medicines. bottles and so on all kinds of plastie bottles, glass bottles, PVC, PET, PS, such as tin containers.

Film wrapping packaging machine

This sleeve shrink wrapping machine and packaging equipment with scales is a new type of packing machine which combines merits of both domestic land and abroad similar machinery. It is widely used in beverage, food, medical-chemical combinative package. It can package perfectly whatever it is without pallet, cartoon, rectangle, round or flat shape. It applies PLC automatic controller, man-machine interface, ensuring

Hot Searches