- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0-1ml

-

Voltage:

-

220V/380V(by order)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V PACK

-

Dimension(L*W*H):

-

3100*2450*2800mm

-

Weight:

-

4500 KG

-

Warranty of core components:

-

2 Years

-

Product name:

-

Bottle water filling machine

-

Processing Types:

-

Bottle rinsing filling capping

-

Usage:

-

Beverage Filling Packaging

-

Advantage:

-

High Efficiency

-

Control:

-

PLC Touch Screen

-

Filling speed:

-

4000BPH-24000BPH

-

Material:

-

SUS304/316

-

After Warranty Service:

-

Online Support

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Milk, Water, Juice

-

Filling Accuracy:

-

0-1ml

-

Voltage:

-

220V/380V(by order)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V PACK

-

Dimension(L*W*H):

-

3100*2450*2800mm

-

Weight:

-

4500 KG

-

Warranty of core components:

-

2 Years

-

Product name:

-

Bottle water filling machine

-

Processing Types:

-

Bottle rinsing filling capping

-

Usage:

-

Beverage Filling Packaging

-

Advantage:

-

High Efficiency

-

Control:

-

PLC Touch Screen

-

Filling speed:

-

4000BPH-24000BPH

-

Material:

-

SUS304/316

-

After Warranty Service:

-

Online Support

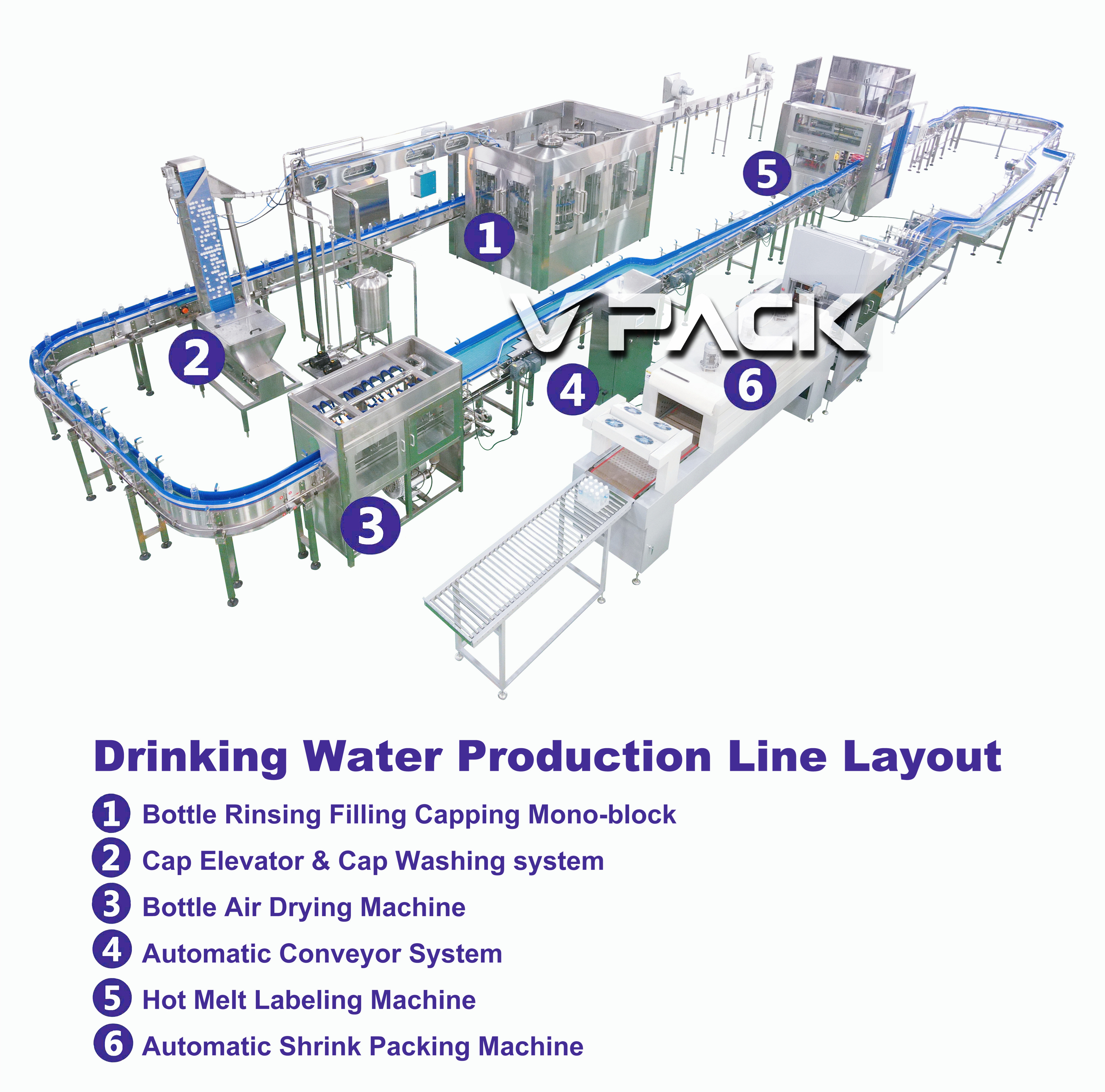

Product Overview

1 - Washing Parts.

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

2 - Air Conveyor.

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

- Rack made by high quality carbon steel welded.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

- Rack made by high quality carbon steel welded.

3 - Filling Parts.

4 - Capping Parts.

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during

capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

5 - Flat Conveyor.

- Energy saving. High efficient. Adapt to customer factory layout

- Special lubrication system, keep products clean, health, safety

- Extended service life

- Electric eyes design keep whole line running safety and quickly

- Overload protection mechanism to effectively ensure the safety of the machine

- Special lubrication system, keep products clean, health, safety

- Extended service life

- Electric eyes design keep whole line running safety and quickly

- Overload protection mechanism to effectively ensure the safety of the machine

Drinking Water Washing Filling Capping 3 in 1

This Drink water bottle filling machine / equipment / production line used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery.Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Main Features

The machine adopts advanced SIEMENS programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectric inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

|

Model

|

Capacity

|

Rinsing heads

|

Filling heads

|

Sealing heads

|

Overall dimensions

|

|

CGF14-12-5

|

6000BPH

|

14

|

12

|

5

|

2400*1900*2800mm

|

|

CGF16-16-5

|

8000BPH

|

16

|

16

|

5

|

2500*1900*2200mm

|

|

CGF18-18-6

|

10000BPH

|

18

|

18

|

6

|

2800*2050*2200mm

|

|

CGF24-24-8

|

14000BPH

|

24

|

24

|

8

|

3100*2450*2800mm

|

|

CGF32-32-10

|

18000BPH

|

32

|

32

|

10

|

3700*2750*2900mm

|

|

CGF40-40-10

|

20000BPH

|

40

|

40

|

10

|

4300*3300*2900mm

|

|

CGF50-50-12

|

24000BPH

|

50

|

50

|

12

|

5200*3700*2900mm

|

|

CGF60-60-15

|

30000BPH

|

60

|

60

|

15

|

6300*4400*2900mm

|

Related products

Automatic 12000B/H 9-Cavity Pet Bottle Blow Molding Machine

1).Use screw of servo driver moving system.

2).Automatic feeding heating and blowing.

3).Patented preform feeding system for easy and safe.

4).Heating system for each lamp adjustment and constant SCR voltage control system.

5).Touch screen human-machine interface for easy operation.

6).Modular component design for easy maintenance.

7).Compact design for effective usage of floor space.

8).Intelligent flow control with high pressure valve.

2).Automatic feeding heating and blowing.

3).Patented preform feeding system for easy and safe.

4).Heating system for each lamp adjustment and constant SCR voltage control system.

5).Touch screen human-machine interface for easy operation.

6).Modular component design for easy maintenance.

7).Compact design for effective usage of floor space.

8).Intelligent flow control with high pressure valve.

12000-15000BPH Rotary Hot Melt Labeling machine (OPP Label)

This hot melt glue plastic bottle label applicator is widely suitable for different material of container and label. The label

cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical models in cost to make mass production and inter grated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, for example changing the label is only needed to change the program, the products concept of that the equipment is designed for users is embodied in everywhere.

Process:Infeed bottle ----- pre-position ----- label cutting ----- gluing -----labeling -----label by press out ---- finish

Automatic shrink film wrapping machine

This type of machine is suit for beverage, drinking water,beer wine and infusion bottle packaging,which can be packed with shrink film .Package will be a firm and beautiful appearance

Main Features

The aircraft used in the pallet with film packaging,widely used in drinks,beer,chemical,food and other

industries.The whole pneumatic expansion support film roll,for the film quickly takes about two minutes to change the film.The film tension transportation,smooth,and precise control of the cutting film neat incision.

Serve control technology can maintain the mechanism of precise synchronization of advanced, reliable delivery.

The heating box, reasonable structure, heat insulation, high precision of temperature control.

Supporting German Siemens, Germany P+F, Japan SMC, Italy motorcycle Rio, the world's most advanced control

System components, equipment, stable operation.Mechanical transmission components using after heat treatment of stainless steel or carbon steel and other materials; spraying the surface quality,The antirust performance.

Main Features

The aircraft used in the pallet with film packaging,widely used in drinks,beer,chemical,food and other

industries.The whole pneumatic expansion support film roll,for the film quickly takes about two minutes to change the film.The film tension transportation,smooth,and precise control of the cutting film neat incision.

Serve control technology can maintain the mechanism of precise synchronization of advanced, reliable delivery.

The heating box, reasonable structure, heat insulation, high precision of temperature control.

Supporting German Siemens, Germany P+F, Japan SMC, Italy motorcycle Rio, the world's most advanced control

System components, equipment, stable operation.Mechanical transmission components using after heat treatment of stainless steel or carbon steel and other materials; spraying the surface quality,The antirust performance.

Our Machine Video

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Machine testing support.

* View our Factory.

We Supply Your Factory Design Service

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

We Supply Your Bottle Design Service

Our Clients' Feedback

Our Company

Packing & Delivery

Recommend Products

Hot Searches