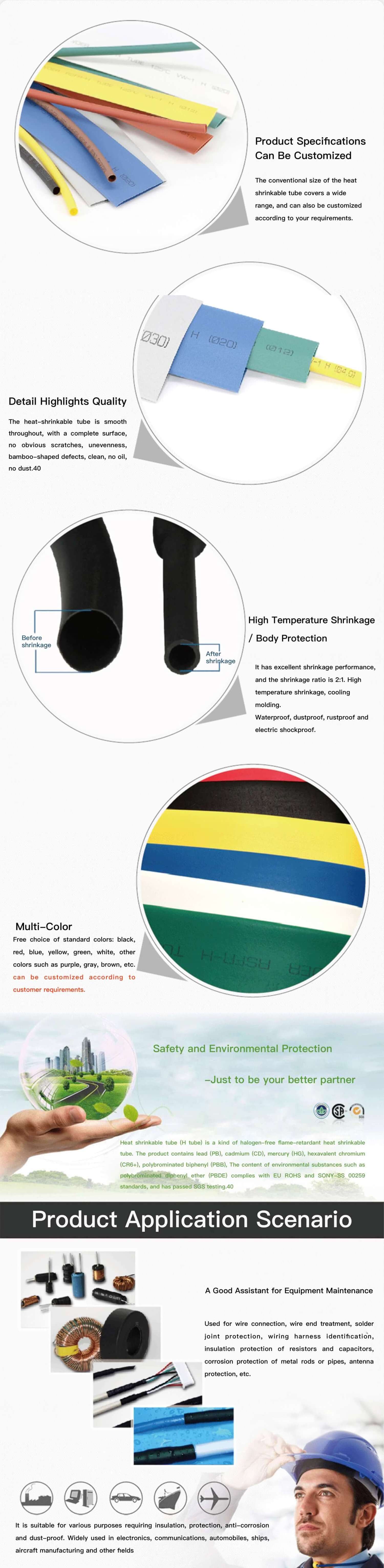

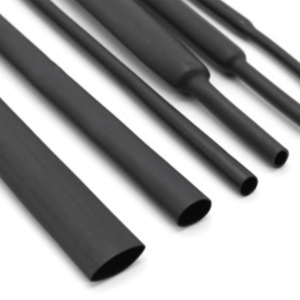

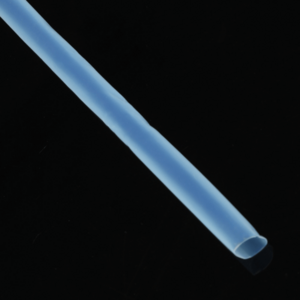

The 125°C

halogen-free

environmentally friendly

flame-retardant

heat-shrinkable tube is made of radiation cross-linked polyolefin material with excellent physical, chemical and electrical properties. And has flame retardant properties, widely used in the automotive wiring harness, electronic components, communications and other fields.

✦ Executive standard: UL224, CAN/CSA C22.2 NO198.1-99

✦ Shrink ratio: 2:1

✦ Initial shrinkage temperature: ≥+84℃

✦ Full shrinkage temperature: ≥+125℃

✦ Use temperature: -55℃~+125℃

✦ Halogen-free, low-smoke, non-toxic, soft, flame retardant

✦ Environmental standards: RoHS, IPC/JEDEC-J-STD-709 , H-class materials

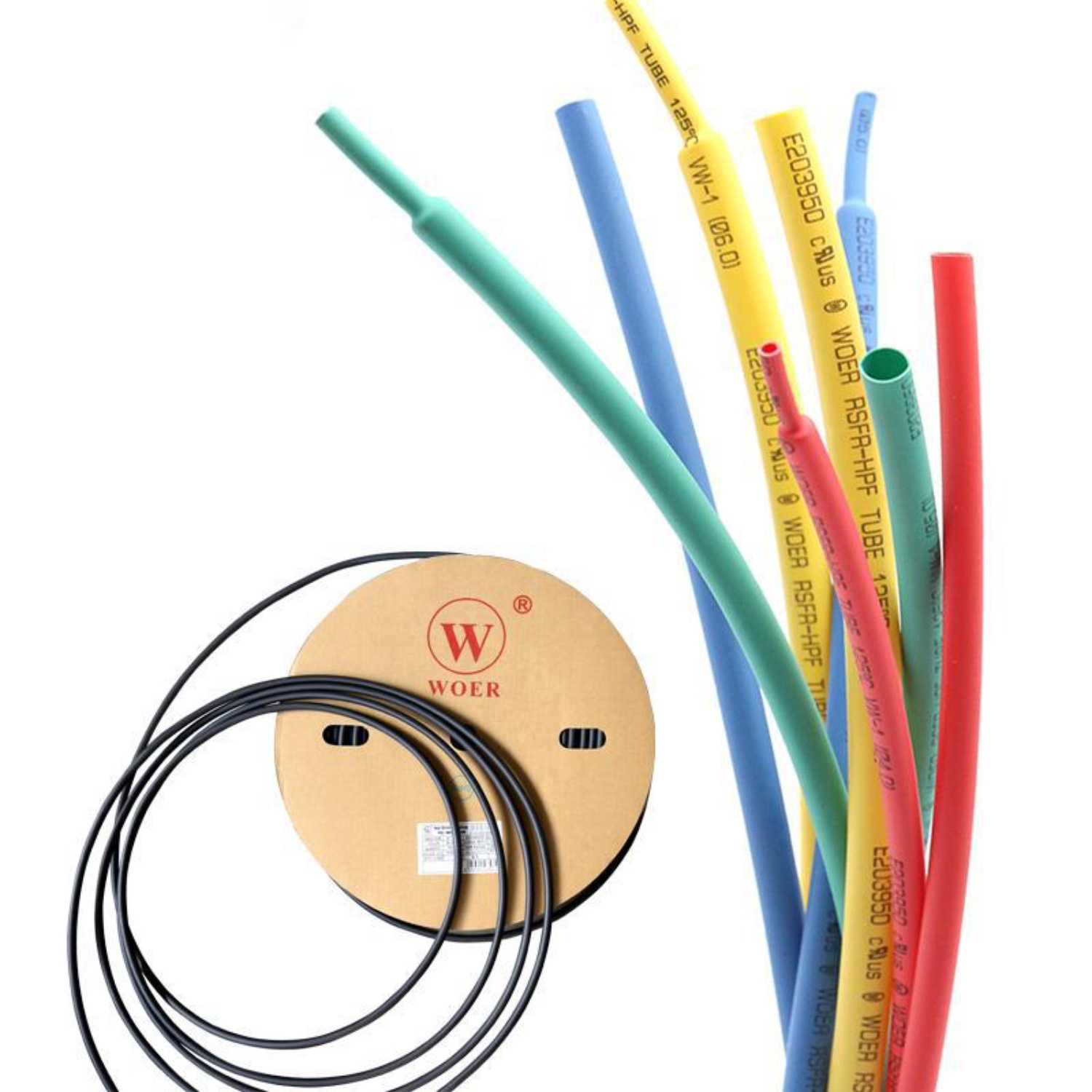

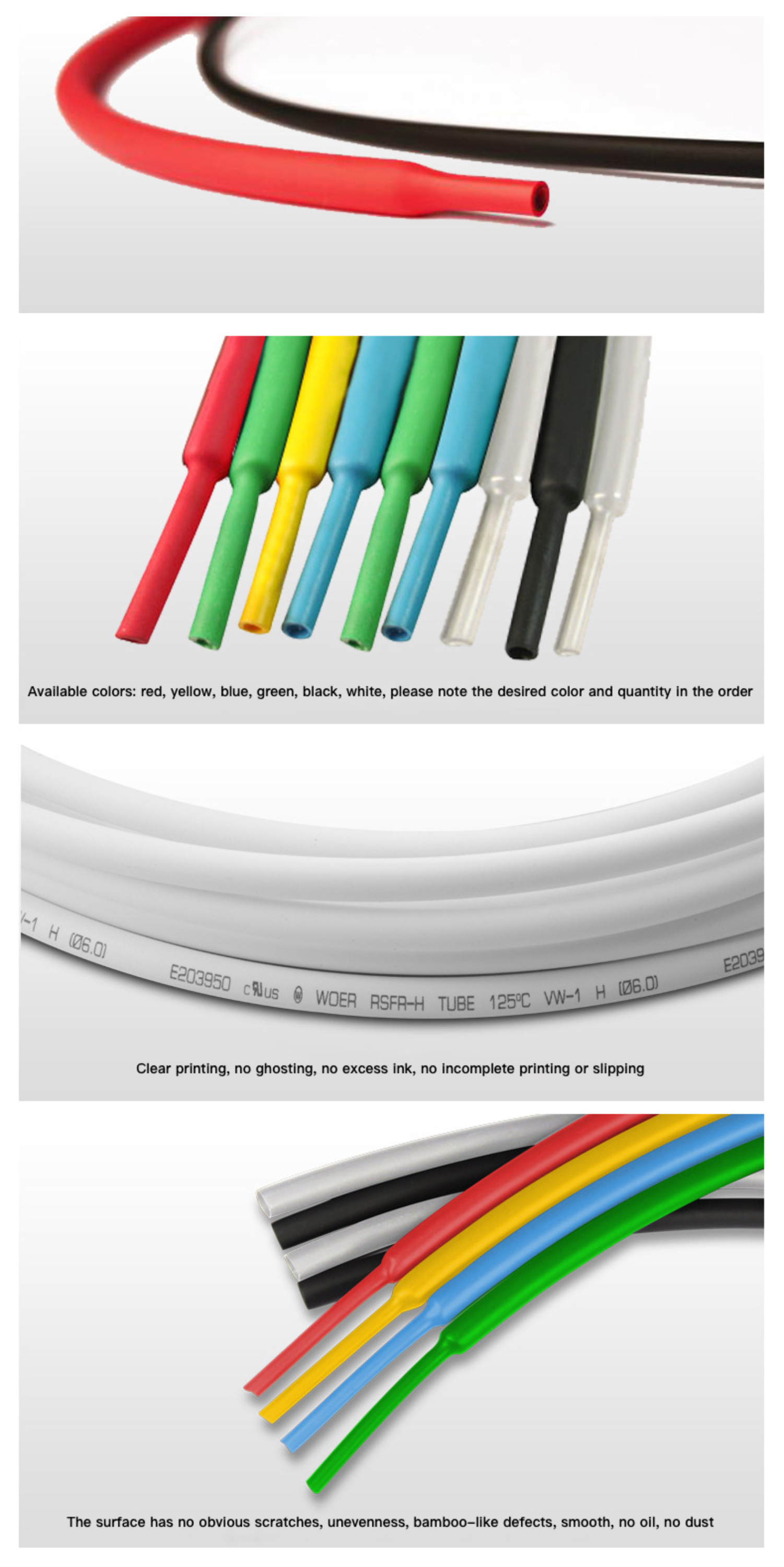

✦ Standard colour: ten international standard colours such as black, white, red, yellow, green, etc.

Technical Data