- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

3 Phase 380V 50Hz

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

1250*850*1650mm

-

Weight (KG):

-

880

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

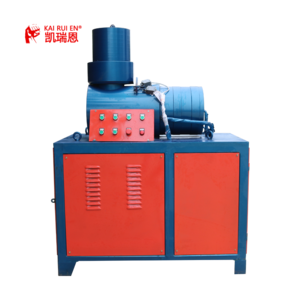

Reinforced Rebar pier head Cold Upsetting Forging Machine

-

COLOR:

-

YELLOW, RED, GREEN, customized

-

process rebar range:

-

12-40mm

-

capacity:

-

10-15s/pcs

-

function:

-

Reinforced upsetting machine | upset forging machine

-

Application in:

-

rebar head upsetting machine | rebar upsetting machine

-

Application:

-

Rebar end forging machine | Rebar Cold Upsetting Forging Machine

-

Usage:

-

steel bar cold forging machine | upset forging machine

-

used for:

-

spiral rebar forcing machine | Reinforced the pier head machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YZ

-

Machine Type:

-

rebar end upsetting rough forging machine

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

3 Phase 380V 50Hz

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

1250*850*1650mm

-

Weight (KG):

-

880

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Reinforced Rebar pier head Cold Upsetting Forging Machine

-

COLOR:

-

YELLOW, RED, GREEN, customized

-

process rebar range:

-

12-40mm

-

capacity:

-

10-15s/pcs

-

function:

-

Reinforced upsetting machine | upset forging machine

-

Application in:

-

rebar head upsetting machine | rebar upsetting machine

-

Application:

-

Rebar end forging machine | Rebar Cold Upsetting Forging Machine

-

Usage:

-

steel bar cold forging machine | upset forging machine

-

used for:

-

spiral rebar forcing machine | Reinforced the pier head machine

The rebar cold forging machine is mainly used for construction of ribbed steel bar rolling straight thread head, it is an important equipment of steel bar connection.

The rebar cold heading machine use the cold heading principle to make the steel end for plastic deformation, diameter increased 4 ~ 6mm, and then processing thread.

The machine has the advantages of compact structure, simple operation, convenient adjustment, good processing quality, fast speed, not affected by environmental conditions. Especially for bridges, subways, power plants and others projects which request high standard of steel bar connections.

Rebar Upset Foring Machine is suitable for upsetting Φ 16mm-32mm HRB335 and HRB400 thread steel. Diameter increased 4 - 6mm after upsetting.

|

Model

|

YZGJ-40

|

|

processing rebar range

|

12-40MM

|

|

cylinder diameter

|

220mm

|

|

Motor power

|

7.5kw

|

|

reted power

|

380v, 50hz, three phase

|

|

working pressure

|

80Mpa

|

|

Dimension

|

1250*850*1650mm

|

|

weight

|

880kg

|

Feature

1.It can process steel bars with diameter ranging from 12-40mm.

2.It greatly improves the tensile strength of the joint

3.High efficiency, can produce 300-500 pieces per machine.

4.Environmental protection, safety, economy,low cost.

Trade Assurance Transaction History:

Zhengzhou Yize engaged in a wide range of machine business, We are in this line for more than 10 years. We provide best quality

machines and solutions for global users in machinery fields. Some of them also visit us and check our machines. From the single

machine to the automatic product line, From china to the whole world. Zhengzhou Yize committed to machine manufacturing and high

efficiency producing. We also have development on new material and key technology. We welcome you to visit us and make a deal.

|

MOQ

|

Usually 1 set, or based your order, Preferential wholesale price.

|

|

|

||

|

Voltage

|

110V /220V /380V /415V, 50/60 HZ Single/Three phase , Customize the voltage according to your local voltage.

|

|

|

||

|

Guarantee

|

Quality guarantee term is for one year, During guarantee period, free technical support and free spare parts supply.

|

|

|

||

|

Payment term

|

T/T, Credit card, Western Union, RMB , Alipay, Wechat, Cash, E-checking, MoneyGram, L/C, etc.

|

|

|

||

|

Documents offer

|

By express:express waybill

By air:airway bill

By sea:B/L, commercial invoice, packing list, sales contract, CO, FE, FTA or as your request. |

|

|

||

|

How to install and maintain the machine

|

we can teach you install or maintain the machine by video, email ,pictures.....if large project , we can arrange our engineer help you to install or maintain it in your country. If you need spare parts, we can supply for free or cost price, you pay express cost.

|

|

|

||

|

Assignment of engineers and training

|

we can supply manual book, work video, install video, pictures first, we can also assign our engineers to go abroad for installing or training machines for our users.

|

|

|

||

Service before sale

1.One-on-one exclusive customer service staff, 24 hours online.

2.Inquiry, email, message will be replied at first time.

3.Supply professional technical parameters, video picture sharing, project design.

Service on sale

1.Ensure customer payment security.

2.Ensure the customer's price is stable and reasonable.

3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good.

Service after sale

1.Arrange high-efficiency delivery and safe transport.

2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.