- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

1250*850*1650mm

-

Weight (KG):

-

450

-

Name:

-

upsetting machine

-

Usage:

-

forging rebar,steel bar.

-

Processing reinforcement range:

-

12-40mm

-

Working pressure:

-

80Mpa

-

Cylinder diameter:

-

220mm

-

Efficiency:

-

300-500 pieces

-

Type:

-

Single cylinder,double cylinder

-

Feature:

-

High efficiency

-

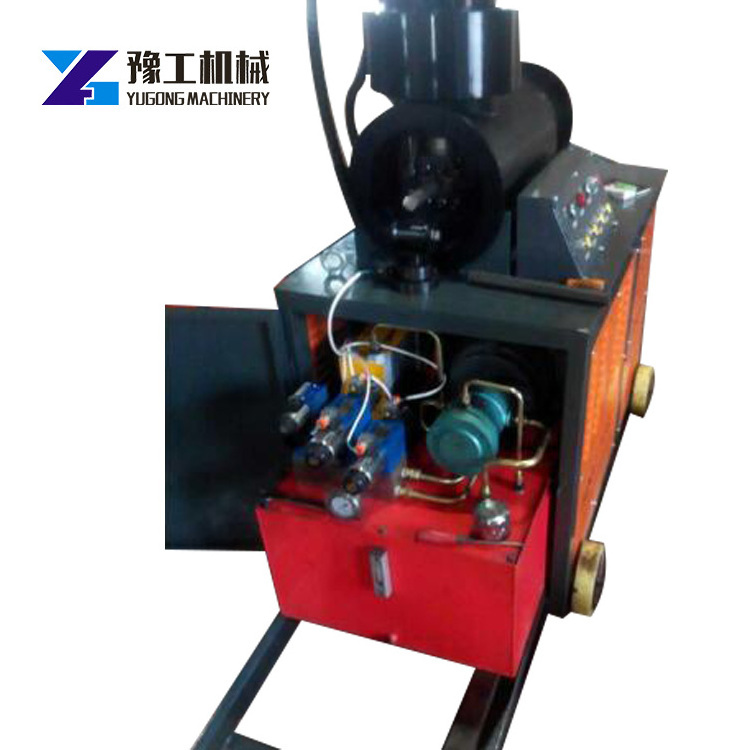

Color:

-

Red,Costomized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Machine Type:

-

Automatic

-

Voltage:

-

220V/380V

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

1250*850*1650mm

-

Weight (KG):

-

450

-

Name:

-

upsetting machine

-

Usage:

-

forging rebar,steel bar.

-

Processing reinforcement range:

-

12-40mm

-

Working pressure:

-

80Mpa

-

Cylinder diameter:

-

220mm

-

Efficiency:

-

300-500 pieces

-

Type:

-

Single cylinder,double cylinder

-

Feature:

-

High efficiency

-

Color:

-

Red,Costomized

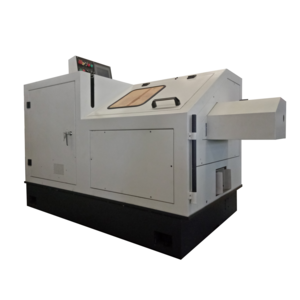

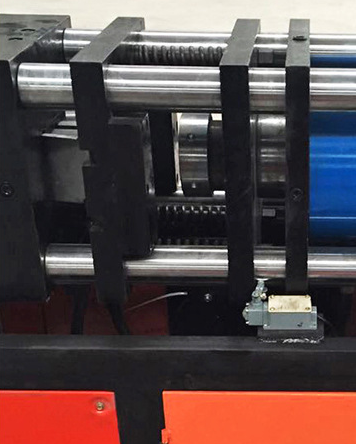

Metal Pressing Machine Iron Press Forging Rebar Cold Heading Forge Machine

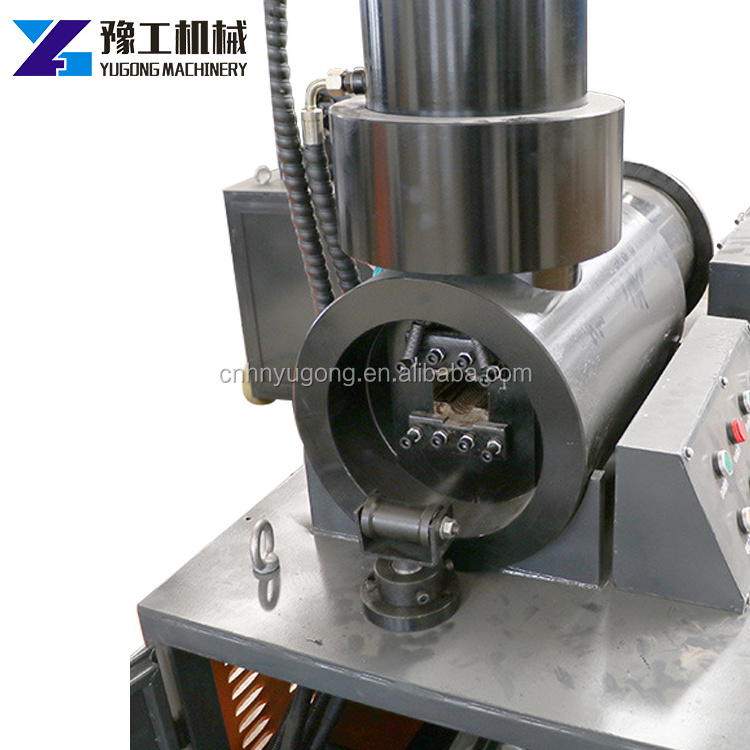

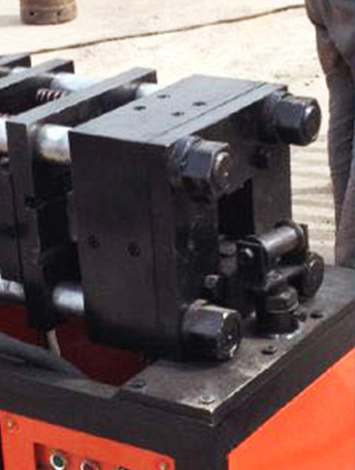

Steel upsetting machine using hydraulic cold heading of the principle of plastic deformation of steel ends, the diameter increases 4 ~ 6mm, and then processing thread.

This upsetting of the threaded connector by the tensile test of all broken in the base metal for the higher requirements of engineering steel upsetting machine hydraulic technology, upsetting steel for straight thread connection technology, the use of sleeve connector . The device is suitable for the diameter of 16 ~ 40mmHRB335 (Ⅱ grade steel), HRB400 (Ⅲ grade steel) hot-rolled ribbed steel production upsetting straight thread steel joint.

Technical Parameters

|

Model |

YDCJ-40 |

SYDJ-40 |

|

Upsetting R ange |

16-40mm |

16-32mm |

|

Upsetting F orce |

2036KN |

|

|

W orking S troke |

220mm |

220mm |

|

Motor Power |

7.5kw |

7.5kw |

|

Power |

380V |

380V |

|

Oil P ump P ressure |

80Mpa/50HZ |

30Mpa/50HZ |

|

Size |

900×750×500mm |

/ |

|

Max . F low |

5.42L/min |

/ |

|

Upsettin g L ength |

3-5cm |

/ |

|

Increase S ize |

3-5mm |

/ |

|

Work E fficiency |

15-20s/ pieces |

15s/ pieces |

|

Packing Size |

1020×500×965mm |

1250×850×1650mm |

|

Weight |

900kg |

1000kg |

Product Features and Details

a. High production efficiency,each hour can be upsetting 300-500 head.

b. Processing a wide range of steel,which can be processed in line with HRB335 (Ⅱ grade steel), HRB400 (Ⅲ grade steel) standard Φ16-Φ40mm,various specifications of the steel.

c. Equipment failure rate is small,non-fragile parts construction costs low.

d. Environmental protection,security,it is not subject to environmental and climates changes.

e. The end of the steel cross-sectional area expanded into the bottom diameter of the screw thread of base metal,fully play the tensile strength.

Production Application

Upsetting machine can be used with steel rolling machine, straight thread sleeve, suitable for demanding engineering

1. Package: Wooden case.

S mall order: we suggest DHL/UPS/TNT/FEDEX or by air .

Bulk order: we suggest by air or by sea through the t erms :EXW, FOB, CFR, CIF, CPT, CIP, DAF, etc.

2. Shipping: It is according to the model and quantity.

Generally it is 3-5 days if the machines are in stock.

It will be 15-30 days if you want to customize the machines.