- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FTM

-

Dimension(L*W*H):

-

refer to model

-

Product name:

-

oller press mineral powder charcoal coal dust briquette machine

-

Application:

-

Briquette Production

-

Keyword:

-

Briquette Forming Machine

-

Raw material:

-

Charcoal Powder

-

Color:

-

Demand

-

Briquette shape:

-

Required

-

Voltage:

-

Customized

-

Installation:

-

Engineers' Guidance

-

After sales provided:

-

Engineer available overseas

Quick Details

-

Weight (KG):

-

0

-

Production Capacity:

-

1-35tph

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTM

-

Dimension(L*W*H):

-

refer to model

-

Product name:

-

oller press mineral powder charcoal coal dust briquette machine

-

Application:

-

Briquette Production

-

Keyword:

-

Briquette Forming Machine

-

Raw material:

-

Charcoal Powder

-

Color:

-

Demand

-

Briquette shape:

-

Required

-

Voltage:

-

Customized

-

Installation:

-

Engineers' Guidance

-

After sales provided:

-

Engineer available overseas

Product Description

Our briquetting machine is designed to press powders with a size less than 8 mm and a humidity less than 10% into spherical shapes. The balls are small and easy to burn, smelt, store, and transport, thus they are very popular in coal, barbecue (BBQ), metallurgy, heating, and other industries.

For the final formed balls, we support customizing different shapes and sizes:

- Shape: Round, square, pillow, oval or other special shapes

- Output Size: 20–75 mm

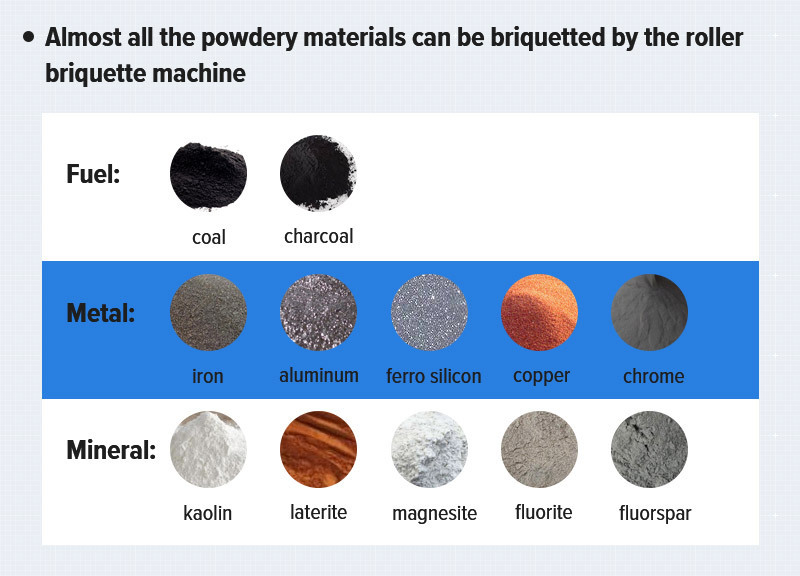

Applicable Materials:

- Coal powder: Coal slurry, coal dust, coal fines, fly ash

- Charcoal powder: Carbonized coconut shells, rice husks, sawdust, etc.

- Metal powder: Mill scale, steel slag, oxide scale, iron powder, manganese ore powder, etc.

- Non-metallic powder: Gypsum, asphalt powder, ore tailings, etc.

The Structure of the Briquetting Machine

The briquetting machine features a simple structure and a concise process. It consists primarily of the feeding part, transmission part, and forming part. The key component of this machine is the pressure roller, which can be pressed into high-quality spherical products.

1. Pressure roller: Main wearing part. It is forged from wear-resistant alloy materials 65Mn and 9Cr 2 Mo. It presses soft materials (coal powder, carbon powder, bentonite powder, etc.) and hard materials (iron powder, copper powder, chromium powder, etc.) wait). It is versatile and replaceable after wear, capable of producing square, round, oval, and pillow-shaped products.

2. Bearing: It adopts rolling mill bearing series and undergoes quenching and tempering treatment.

3. Steel plate: The steel plate is spray-coated with four layers of paint, which is waterproof, acid-proof, powder-proof and sun-proof, making the briquetting machine durable.

What are the outstanding advantages of our briquetting machine?

- Rapid molding: It exhausts materials fully within 3-5 seconds, ensuring high density, strength, and a high rate of spherical formation.

- High-quality briquettes: The finished product has a complete shape and can withstand 10 drops without breaking. It also has high carbon content (more than 90%), low moisture (less than 5%), good flammability, smokeless and odorless.

- Diverse shapes: By replacing molds of different shapes, this machine can produce products of various shapes and specifications.

- Long service life: The surface of the mold is made of special synthetic manganese steel material. The gear adopts hard tooth type, which improves the performance and service life of the reducer.

- Easy operation and maintenance: Advanced PLC program control, stable hydraulic system, and mature vibration molding technology ensure that the machine operates fully automatically and stably.

Briquetting Machine Working Principle

The motor rotates to drive the hydraulic pump to work, and the hydraulic oil in the oil tank is transmitted to each cavity of the hydraulic cylinder through the oil pipe. The piston rod of the oil cylinder is driven to move longitudinally, thereby pressing and forming the material in the mold.

View the working principle of the briquetting machine

|

Model |

Roller Diameter

(mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

Henan Fote Heavy Machinery Co., Ltd was founded in 1982 in Zhengzhou, Henan, the capital of Chinese machinery manufacturing. The company is large in scale and has four major production bases with a total area of 500,000 square meters, of which standardized heavy industry plants cover an area of 360,000 square meters, providing advanced and reliable infrastructure for production.

Our company focuses on the development and production of mining machinery, including crushers, mills, beneficiation equipment, briquette machines, rotary kilns and other products, which are widely used in mining, chemical industry, construction, coal, ceramics, and other industries. With excellent quality and professional solutions, it has won the trust of customers around the world.

1. We provide customers with a full range of services, including solution design, technical process planning, and the design and manufacturing of standard and non-standard equipment.

2. We dispatch professional technicians to the customer site to assist with shell welding, equipment installation, adjustment, and training of operators.

3. We visit customers regularly to provide lifelong service and technical support.

4. Except for wearing parts, we provide one-year warranty, long-term supply of spare parts, and two-year maintenance of major parts if used correctly.

1. Our equipment holds ISO 9001, CE, and GOST certifications and all equipment undergoes pre-wiring, assembled, and factory tested at our manufacturing facility.

2. We take a test on each machine before delivery.

1. How to get the best price for equipment?

- We are the direct manfacturer, so we can offer you the lowest price than the market price.

- The price of the machine can be given the largest discount based on quantity.

2. Our payment term

- Paypal, T/T, L/C, and Western Union are all available.

- 30% deposit in T/T advance, 70% balance before shipment.

- We take photos of finished products before delivery.

3. Delivery time

- Streamlined production allows for prompt delivery of most products within 6-8 weeks.

- The delivery time will be based on the machine type, selected shipping method, and parts availability.

4. Packaging

- The equipment is wrapped in plastic film before packaging to avoid moisture at sea.

- Bare machines are packed in export containers.

- The motors and small parts are packed in waterproof, sealed, and sturdy wooden cases.

5. Transportation

- Standard container or bulk cargo transportation.

- Sea transportation, air transportation, land transportation, according to customer requirements.

- Complete shipping options and best services at lowest prices are provided: MSC, APL, COSCO, OOCL, CSCL, MSC, MSK, KLINE, etc.

- Seaports in normal use: Qingdao, Tianjin, Shanghai.

- We promise that your goods will be delivered to the destination promptly and safely, and will remind you before the ship arrives.

If you need quality machinery with the latest technology, best prices and fastest delivery, our company is your answer. You are welcome to visit our company and workshop, we sincerely look forward to cooperating with you.