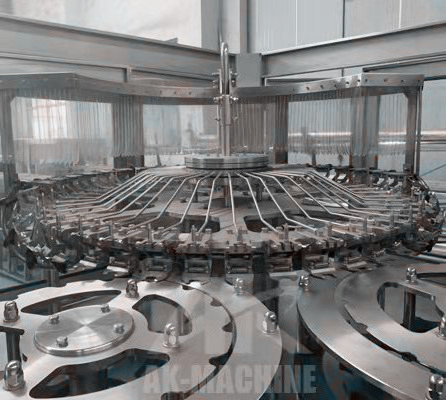

2.Using unique design,a

void the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the pollution.

3.Washing pump is made of

stainless steel.

4. By high spray nozzle, blunt bottle of water jet ang

les, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

5.

B

ottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion resistant bearing without maintenance.