- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

9500*1200 * 1300mm

-

Weight:

-

5800 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot Product

-

Product name:

-

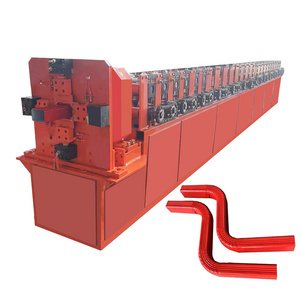

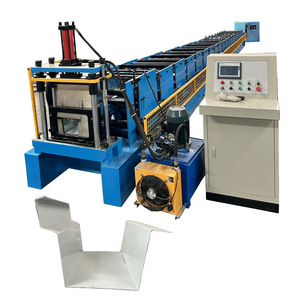

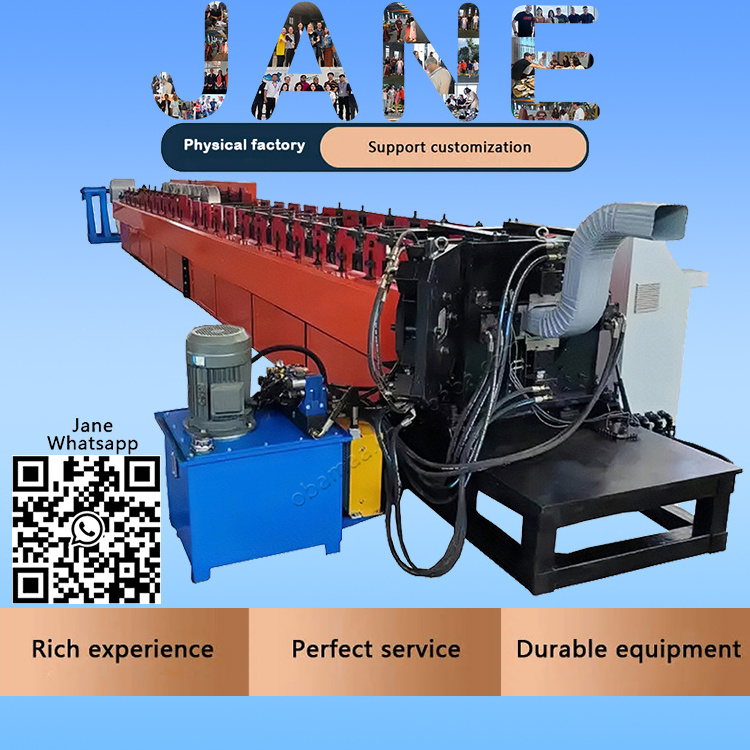

Downspout Roll Forming Machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Roller material

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Usage:

-

Galvanize roof sheets machine

-

Screen:

-

Color touch screen

-

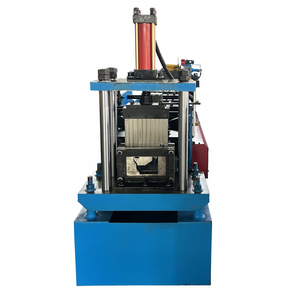

Cutting type:

-

Hydraulic Cutting

Quick Details

-

Type:

-

Downpipe machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10-15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

9500*1200 * 1300mm

-

Weight:

-

5800 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot Product

-

Product name:

-

Downspout Roll Forming Machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Roller material

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Usage:

-

Galvanize roof sheets machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Products Description

Downspout Roll Forming Machine

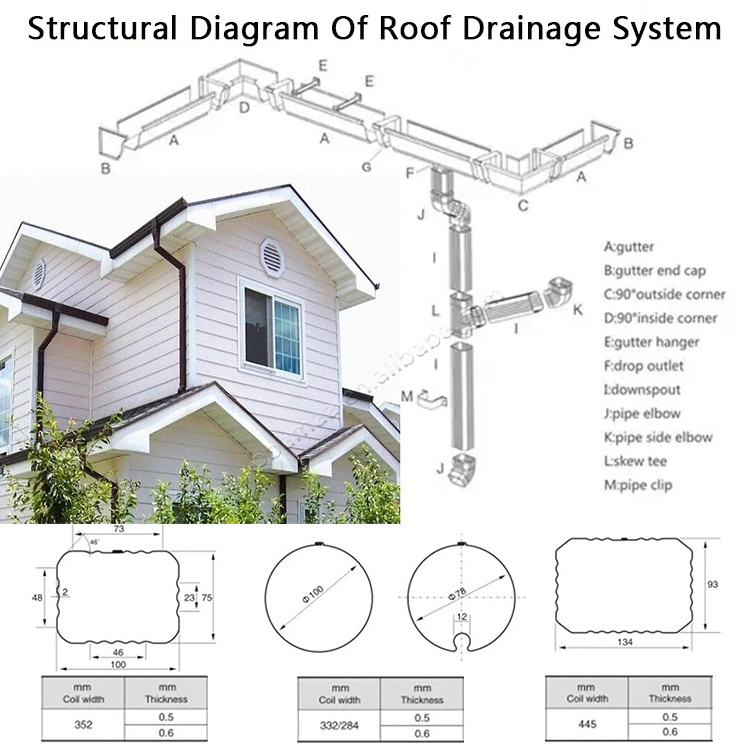

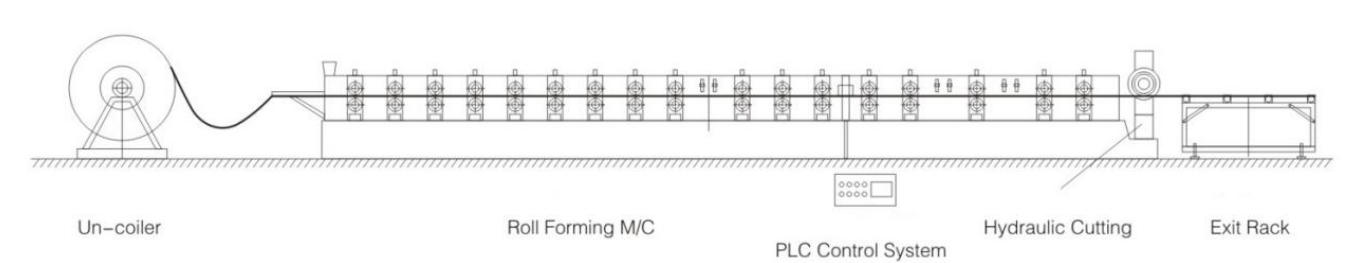

This roof gutter roll forming machine is for steel or aluminum sheet cold form industries. It can form rain gutter profiles according to customer’s requirement continuously, automatically cut to length. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production. Therefore, it is really a new type of energy-saving and high-effective equipment for metal rain gutters. And it has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

Work processing

Specification

|

Downspout Roll Forming Machine

|

|

|

||

|

No

|

Item

|

Specification

|

||

|

1

|

Coil Width

|

According to drawings

|

||

|

2

|

Diameter of shaft

|

70mm

|

||

|

3

|

Productivity

|

10-15m/min

|

||

|

4

|

Middle plate

|

16mm

|

||

|

5

|

Material of shaft

|

45#steel with tempering

|

||

|

6

|

Forming Thickness

|

0.3mm-0.8mm

|

||

|

7

|

Material Of Rollers

|

45#steel

|

||

|

8

|

Cutting Type

|

Hydraulic Cutting

|

||

|

9

|

Main power

|

5.5Kw

|

||

|

10

|

Pump Station Motor

|

4Kw.Lichao Brand

|

||

|

11

|

Main frame

|

300H steel

|

||

|

12

|

Control system

|

PLC

|

||

|

13

|

Dimensions(L*W*H)

|

About 9500*1200*1300mm

|

||

|

14

|

Weight

|

About 5800kgs

|

||

Product Details

Fully automatic computer operation, easy to use, convenient and responsive.

The frame structure is welded with carbon steel plates, which has a long service life.

Carefully selecting materials is the key to making good products.

On demand production, welcome to customize with pictures.

Low noise operation and short flattening time.

Good bearing capacity and easy operation.

Sample Room

Finished product effect for your reference.

The following are the products produced by our machine. Please check the rolling forming effect.

Related Plate Type

Glazed Tile Type Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Other Product

Packing&Delivery

Hot Searches