- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2500

-

Brand Name:

-

HWASEN

-

Place of Origin:

-

Zhejiang, China

-

Die Size(mm):

-

0.01 - 0.02 mm

-

Model Number:

-

SJ55-800

-

Year:

-

2022

-

Voltage:

-

220V/380V,3phase

-

Dimension(L*W*H):

-

5.0X2.2X4.8m

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

suitable material:

-

HDPE, LDPE,LLDPE,

-

die head:

-

fixed or rotary die

-

scrw diameer:

-

50mm

-

product type:

-

PE film

-

cooling:

-

air blower

-

film type::

-

tubular

-

Weight:

-

1500KG

-

Power:

-

30KW

Quick Details

-

Output (kg/h):

-

50 - 55

-

Number of Layers:

-

Single-layer

-

Screw diameter (mm):

-

55

-

Weight (KG):

-

2500

-

Brand Name:

-

HWASEN

-

Place of Origin:

-

Zhejiang, China

-

Die Size(mm):

-

0.01 - 0.02 mm

-

Model Number:

-

SJ55-800

-

Year:

-

2022

-

Voltage:

-

220V/380V,3phase

-

Dimension(L*W*H):

-

5.0X2.2X4.8m

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

suitable material:

-

HDPE, LDPE,LLDPE,

-

die head:

-

fixed or rotary die

-

scrw diameer:

-

50mm

-

product type:

-

PE film

-

cooling:

-

air blower

-

film type::

-

tubular

-

Weight:

-

1500KG

-

Power:

-

30KW

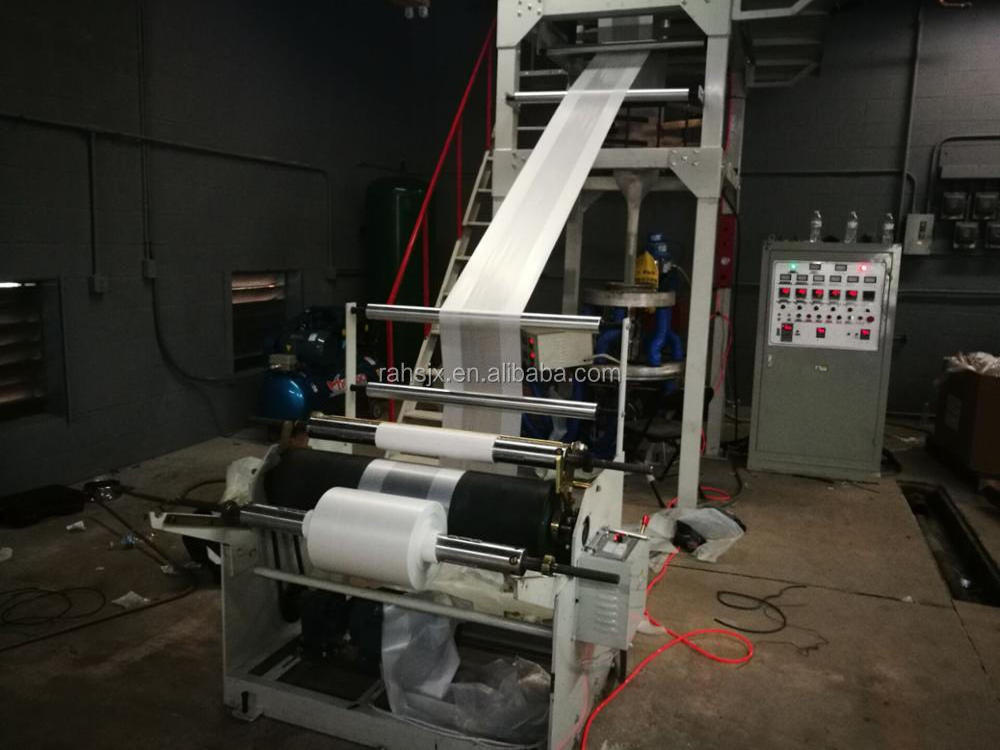

SJ50-600 single layer HDPE trash bag film roll extruder machine

Useful:

This machine is suitable for blowing high-density polyethylene (HDPE), low density polyethylene (LDPE)

and linear low density polyethylene (LLDPE) plastic film, widely used in food, clothing, textiles, daily use

articles and industrial products such as packaging. Formula can be raw materials through production

pearl film and degradation film.

Features:

1 screw and barrel are used 38CRMOALA alloy by nitrogen treatment and precision machining, high

hardness, corrosion resistance and durability.

2 die hard chrome plating, the screw mandrel type structure, the molten material out of uniform, blown

film has fine finishing: blower is of labyrinth structure, even air output. Unit adopts lifting type according to

different process requirements for lift adjustment.

3. Coiling unit adopts pressure friction rewinding or center rewinding, driven by torque motor, rewinding and

changing easy.

Main technical specification:

|

Model |

SJ-50-600 |

SJ-55-800 |

SJ-60-1000 |

SJ-65-1200 |

|

|

Screw diameter |

50mm |

55mm |

60mm |

65mm |

|

|

L/D ratio |

28:1 |

28:1 |

28:1 |

28:1 |

|

|

Screw speed |

10-120rpm |

10-120rpm |

10-120rpm |

10-120rpm |

|

|

Screw material |

SACM-645/38 CRMOALA |

||||

|

Single layer thickness |

0.003-0.12mm |

0.003-0.12mm |

0.003-0.12mm |

0.003-0.12mm |

|

|

Film width |

600mm |

800mm |

1000mm |

1200mm |

|

|

Main motor |

11kw |

18.5kw |

22kw |

30kw |

|

|

Total motor |

18kw |

26kw |

31kw |

45kw |

|

|

Output capacity |

20-35kg/h |

25-50kg/h |

30-60kg/h |

40-75kg/h |

|

|

weight |

1800kg |

2000kg |

2300kg |

2500kg |

|

|

dimension |

4.3 × 2.3 × 4m |

4.5 × 2.5 × 4.2m |

4.7 × 2.7 × 4.6m |

4.9 × 3 × 4.8m |

|

High Quality PE film blowing machine :

|

Name |

|

Rotary die head |

|

Double rewinder and cutter |

|

Embossing roller |

|

Auto loader |

|

Auto lift traction |

|

Air shaft |

|

Mechanic screen changer |

|

Air compressor |

|

Corona treatment |

PE Film Shopping Bag Film Blowing Extrusion Machine

1) control box

2) Traction part

3) main extruder

4) completely machine plant