- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM

-

Cavity:

-

Single

-

Mould Steel:

-

1.2344,1.2343,1.2767,NAK80 etc

-

Mould Base:

-

LKM,HASCO,DME

-

Certification:

-

ISO9001 and as per customer requiements

-

Toleranc:

-

±0.01mm

-

Surface treatment:

-

Engrave, polishing, texture, harden and as per customer requiements.

-

Mould Life:

-

500 000-1 000 000

-

Hydraulic clinder:

-

Parker,Merkle

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ABERY

-

Model Number:

-

OEM

-

Cavity:

-

Single

-

Mould Steel:

-

1.2344,1.2343,1.2767,NAK80 etc

-

Mould Base:

-

LKM,HASCO,DME

-

Certification:

-

ISO9001 and as per customer requiements

-

Toleranc:

-

±0.01mm

-

Surface treatment:

-

Engrave, polishing, texture, harden and as per customer requiements.

-

Mould Life:

-

500 000-1 000 000

-

Hydraulic clinder:

-

Parker,Merkle

|

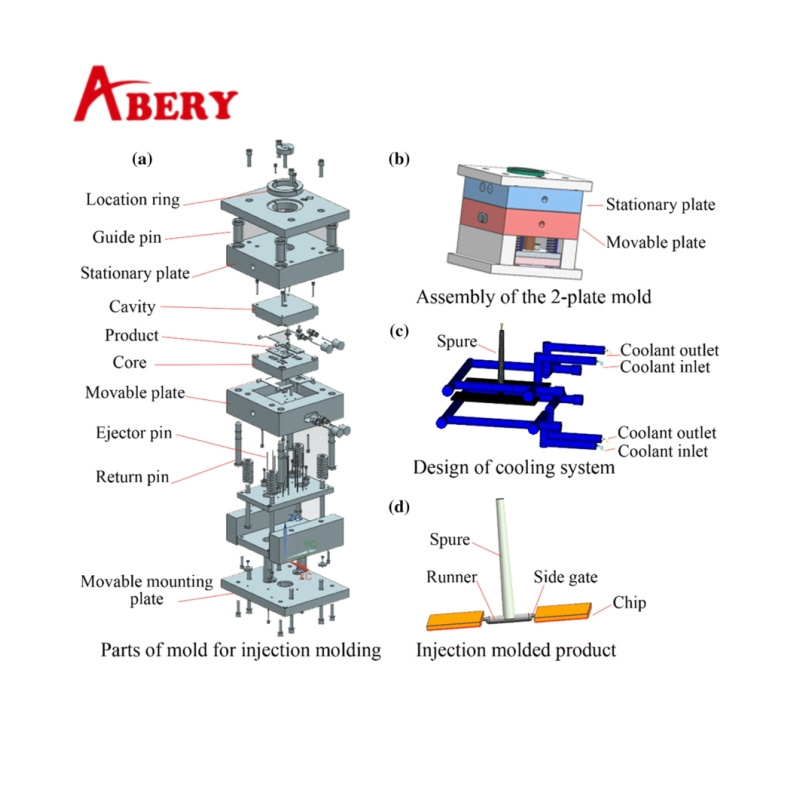

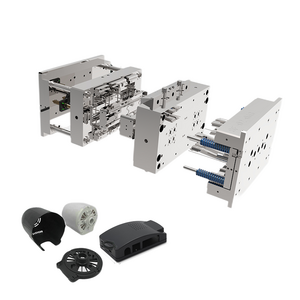

Product Description

|

professional high precision plastic injection parts

|

|

Application field

|

Various plastic injection molded parts for various industrial and automotive applications

|

|

Equipments

|

CNC、EDM、Cutting Off Machine、Plastic Machinery etc.

|

|

Experience

|

14 years experience in plastic injection mold making and and injection molding.

|

|

Certification

|

ISO9001:2015 and relate whole set professional test report

|

|

Quality

|

RoSH and SGS standard

|

|

Plastic Materials

|

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc.

|

|

Mould material

|

P20/ 718H/ S136H/ S136 hardened/ NAK80

|

|

Injection machine

|

50T, 60T, 120T, 150T, 160T, 250T,280T,350T

|

|

Mould life

|

over 500k shots

|

|

Size

|

According to your 2D, 3D Drawing.

|

|

Tolerance

|

± 0.01mm

|

|

Free sample

|

available

|

|

Advantage

|

One stop procurement and Flexible delivery time

|

|

Mould Base

|

SD/LKM Standard/HASCO Standard Self-made

|

|

Design & Program Softwares

|

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc.

|

|

Need to provide

|

2D, 3D, samples, or the size of the multi-angle pictures

|

|

GateType

|

Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate

|

|

Delivery Clause

|

FOB,CFR,CIF,EXW,Express Delivery

|

|

Payment Currency

|

USD, EURO, SGD

|

|

Payment Terms

|

30% deposit by T/T and 70% payment before the delivery by T/T L/C,Money Gram,Credit Card,PayPal,Western Union,Cash Escrow, Other

payments are negotiable

|

Q1:Are you a factory or trading company?

ABERY is plastic mold and injection molding manufacture in SHENZHEN of China,

welcome to visit us.

Q2:How can i get the quotation?

We will submit the quotation in 24 hours if getting detailed information during working days.

In order to quote for you earlier, please provide us the following information together with your inquiry:

1) 3D Step of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3:How you do the quality control?

1). Materials inspection by IQC;

2). During processing, our IPQC will check the injection molded parts every

3). Hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouses

5). 100% inspected by QC before shipping out.

Q4:What should we do if we receive defective products?

If receive defective product, please send us the photos, we will feedback to ourengineers and QC departments and solve the problems ASAP.

Q5:How to pack the moulds and products?

1). For moulds, we will be coated one_layer anti_rust oil first, and then also will be

covered thin films on the mould, finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer's

request to pack.

Hot Searches