- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1900kg

-

Steam valve diameter:

-

DN25

-

Relief valve diameter:

-

DN25/DN20

-

Rated power voltage:

-

220v

-

Power consumption:

-

4.8Akw/h

-

Fuel consumption:

-

50-100kg/h

-

Evaporation:

-

600kg/h

-

Control system:

-

LED screen automatic control

-

Material:

-

International standard stainless steel

-

Rated working pressure:

-

0.7MPa

-

Color:

-

Color Optional

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinda Boiler

-

Dimension(L*W*H):

-

2500*900*1900mm

-

Weight:

-

1900kg

-

Steam valve diameter:

-

DN25

-

Relief valve diameter:

-

DN25/DN20

-

Rated power voltage:

-

220v

-

Power consumption:

-

4.8Akw/h

-

Fuel consumption:

-

50-100kg/h

-

Evaporation:

-

600kg/h

-

Control system:

-

LED screen automatic control

-

Material:

-

International standard stainless steel

-

Rated working pressure:

-

0.7MPa

-

Color:

-

Color Optional

Product Description

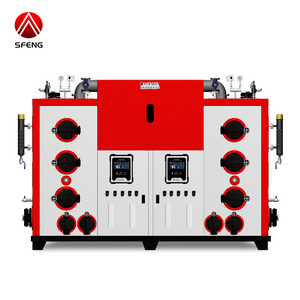

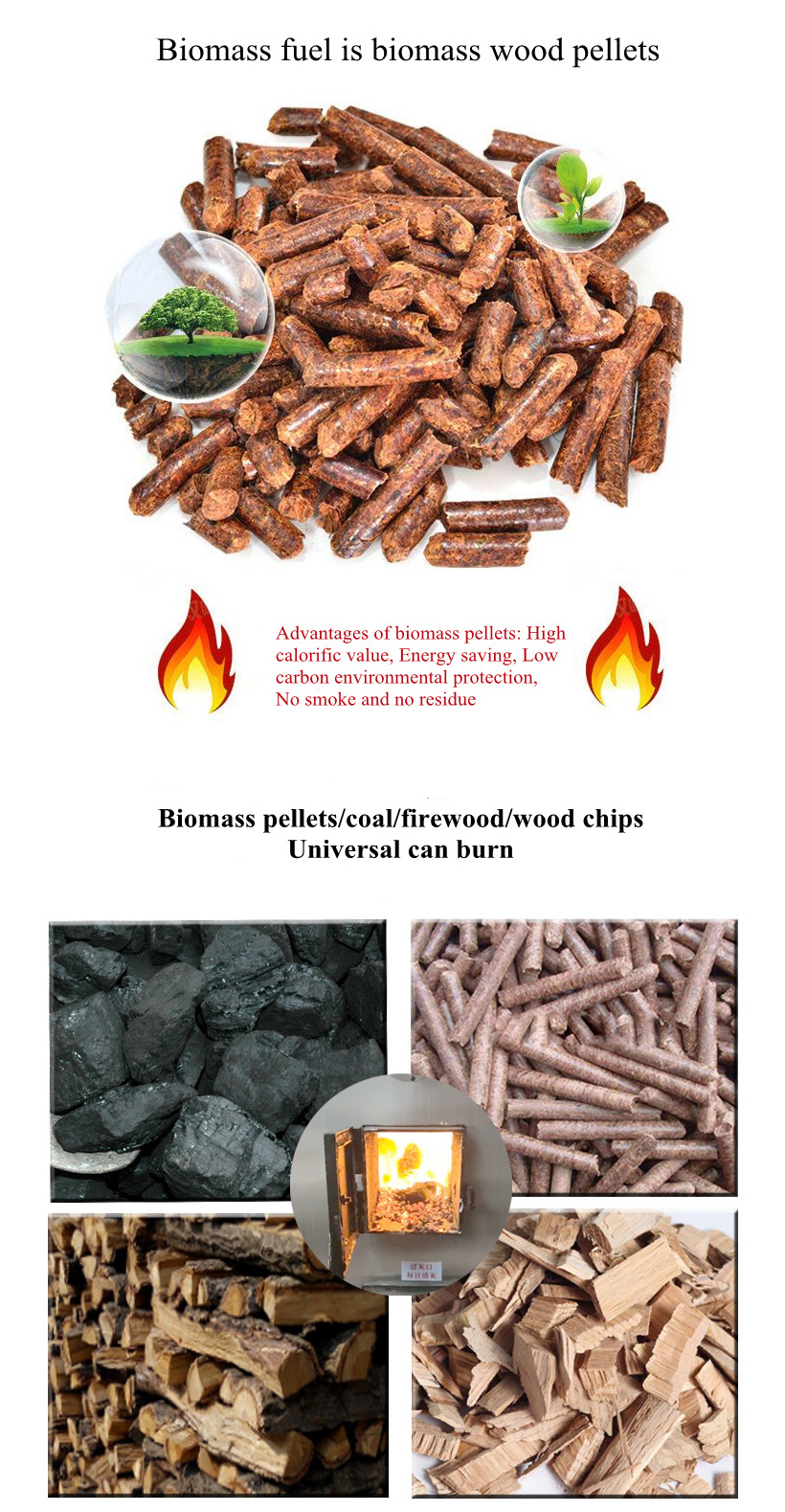

100kg 200kg 300kg 500kg 600kg 800kg Vertical Steam Generator Boilers Biomass Wood Coal Pellet Fired Steam Boiler

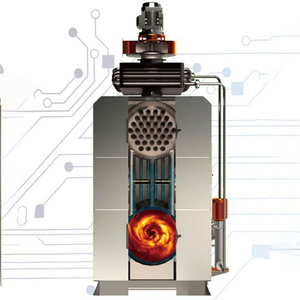

LHG series biomass steam generator description:

Biomass pellet boiler is designed and developed based on the introduction of foreign advanced combustion technology in combination with my country's actual conditions. It has the characteristics of reasonable structure, large heating area, high thermal efficiency, full combustion, no pollution, and low emissions. It adopts mechanical motor screw automatic feeding device to realize mechanized fuel supply, and is equipped with flue gas recovery energy saver. It is the best product to replace electricity, oil, gas and coal-fired steam boilers. Biomass boilers have low operating costs, which can save 40%-60% of operating costs compared to oil, gas, and electric heating boilers. It is a high-efficiency, energy-saving and environmentally friendly thermal energy equipment.

LHG series biomass steam boilers advantage:

1. Configure the dedicated residual heat recovery and dust collector for Xinda. After recovering the high temperature water after recycling the temperature of the waste heat recovery, the high temperature water is replenished in the furnace body.

2. Microcomputer control system, one -click operation,safe and simple.

3. Configure the import pressure controller, high -quality safety valve, with multiple protection such as ultra -pressure, low hydraulic, overheating protection to ensure the safety of the product.

4. The whole machine is leaving the factory. Just connect the power, steam pipeline, water inlet pipe and sewage pipeline. The installation is easy to install and save a lot of installation materials.

Technical Parameter

|

Type

|

LHG0.1

|

LHG0.2

|

LHG0.3

|

LHG0.4

|

LHG0.5

|

LHG0.6

|

|||||

|

Rated Evaporation(kg)

|

100

|

200

|

300

|

400

|

500

|

600

|

|||||

|

Rated Steam Pressure( MPa)

|

0.7

|

|

|

|

|

|

|||||

|

thermal Efficiency

|

>90%

|

|

|

|

|

|

|||||

|

Main Body Dimension(mm)

|

1500*700*1750

|

1700*850*1850

|

1800*900*2100

|

2400*850*1900

|

2500*900*1900

|

2700*900*2100

|

|||||

|

Fuel Storage Capacity

|

110

|

90

|

140

|

180

|

180

|

220

|

|||||

|

Consumption per hour(kg)

|

12-19

|

28-33

|

38-42

|

33-66

|

35-70

|

42-84

|

|||||

|

Weigh(kg)

|

650

|

850

|

980

|

1700

|

1900

|

2100

|

|||||

|

Waste heat recovery dimensions(mm)

|

Diameter400,Length2000

|

|

|

|

|

|

|||||

Accessories

Related Products

Application

Packing&Shipping

Successful Cases

Hot Searches