- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V / 380V

-

Power:

-

7 kw

-

Dimension(L*W*H):

-

1500x600x640mm

-

Weight (KG):

-

800kg

-

Name:

-

Continuous Belt Dryer Machine

-

After-sales Service Provided:

-

Overseas third-party support available, Online support, Video technical support, Free spare parts

-

power:

-

7 kw

-

load weight:

-

15 kg

-

Product name:

-

IR tunnel dryer

-

Heating source:

-

Electricity

-

Usage:

-

Dry Oven

-

Installation:

-

Engineer Guide

-

Certification:

-

CE

Quick Details

-

Type:

-

Flash Drying Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HX

-

Voltage:

-

220V / 380V

-

Power:

-

7 kw

-

Dimension(L*W*H):

-

1500x600x640mm

-

Weight (KG):

-

800kg

-

Name:

-

Continuous Belt Dryer Machine

-

After-sales Service Provided:

-

Overseas third-party support available, Online support, Video technical support, Free spare parts

-

power:

-

7 kw

-

load weight:

-

15 kg

-

Product name:

-

IR tunnel dryer

-

Heating source:

-

Electricity

-

Usage:

-

Dry Oven

-

Installation:

-

Engineer Guide

-

Certification:

-

CE

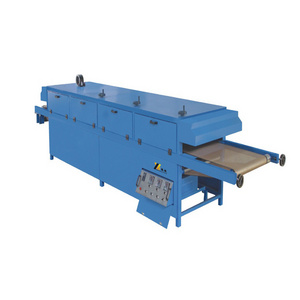

IR Continuous Belt Dryer Machine For Screen Printing Soles Drying

Technical parameters:

Supply power: 220 / 380V 50/60Hz

Power: 7 kw

Load weight: 15kg

Drying cabinet size: 800 x 400mm

Machine size: 1180 x 880 x 890mm

Net weight: 87kg

Gross weight: 93kg

Packing size: 1230 x 980 x 1130mm

Characteristics:

1. The machine adopts far – infrared heating tubes arranged uniformly in the oven

2. The fan in the oven can ensure the temperature in the cabinet well, distributed

3. The machine adopts the electronic grade variable transmission, the speed of the motor is stable and adjustable, and the adjusting range is extensive, when the dry goods go through the 80cm drying tunnel, the slowest speed is up to 50 – 60 seconds

4. The machine can work continuously for more than 5 hours, long time, low noise.

5. There are special designed finishing platform at the entrance, and there are damper regulator at the entrance and exist, these an ensure the heat stability

6. The conveyor belt is stainless steel mesh belt, the other parts adopt advanced electrostatic spraying, easy to clean, no rust

7. The package is excellent, the machine adopts export level fumigation free packing pallet, the transportation is very convenient.

8. The application is widely, and it can be applied to various need heating drying products.

Operation procedures:

1. Power on, turn on the power switch, start the conveyor belt, pre-heating about 5 minutes, open the fan switch (note: when the machine is in the working state, the fan switch must be open) At this time according to the need of the baking content, adjust the room temperature, adjust the knob and the conveying speed, after debugging to the use requirement, it can start normal drying.

2. After the operation, turn off the heating switch, make the delivery motor and the hot air motor to continue running 5 – 10 minutes or so, then, cut off the power supply.

IR tunnel dryer is packed by export wooden case to avoid fumigation,

IR tunnel dryer has warranty 1 year, life time assist maintenance, two extra lamps for spare parts.