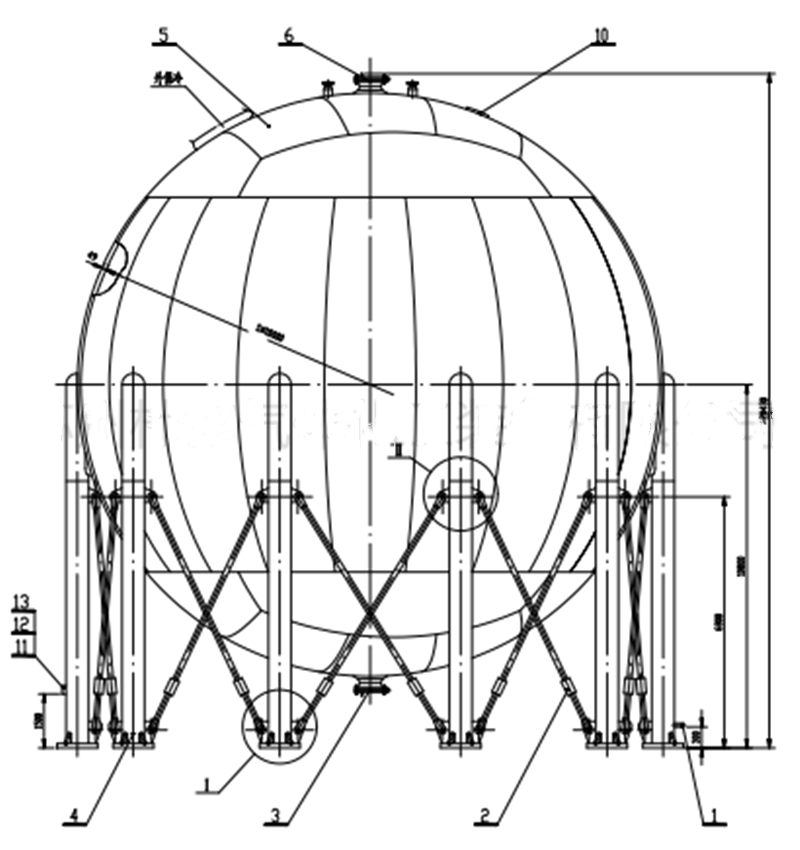

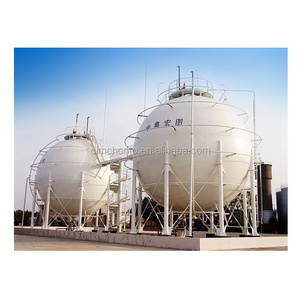

Spherical Type Tank

Spherical shaped storage are used in gas and liquid storage in many industries including midstream, downstream, petrochemical,

chemical, waste water, and aerospace. Spheres can store many products such as anhydrous ammonia, LPG, NGL, gasoline, naphtha, butadiene, ethylene, hydrogen, oxygen, nitrogen, argon, LNG, biogas, sewage gas and waste water.

A spherical shape offers uniform stress

distribution under internal loading resulting in highly efficient pressurized storage. Sphere storage results in the lowest land space for pressurized storage and offers lower costs for

foundations, coatings, accessories, and piping than other options.