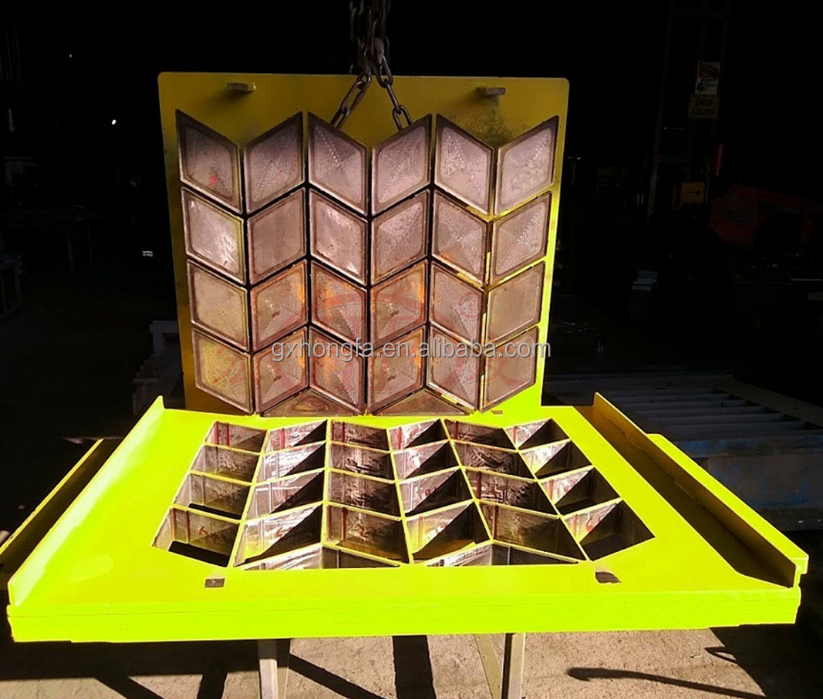

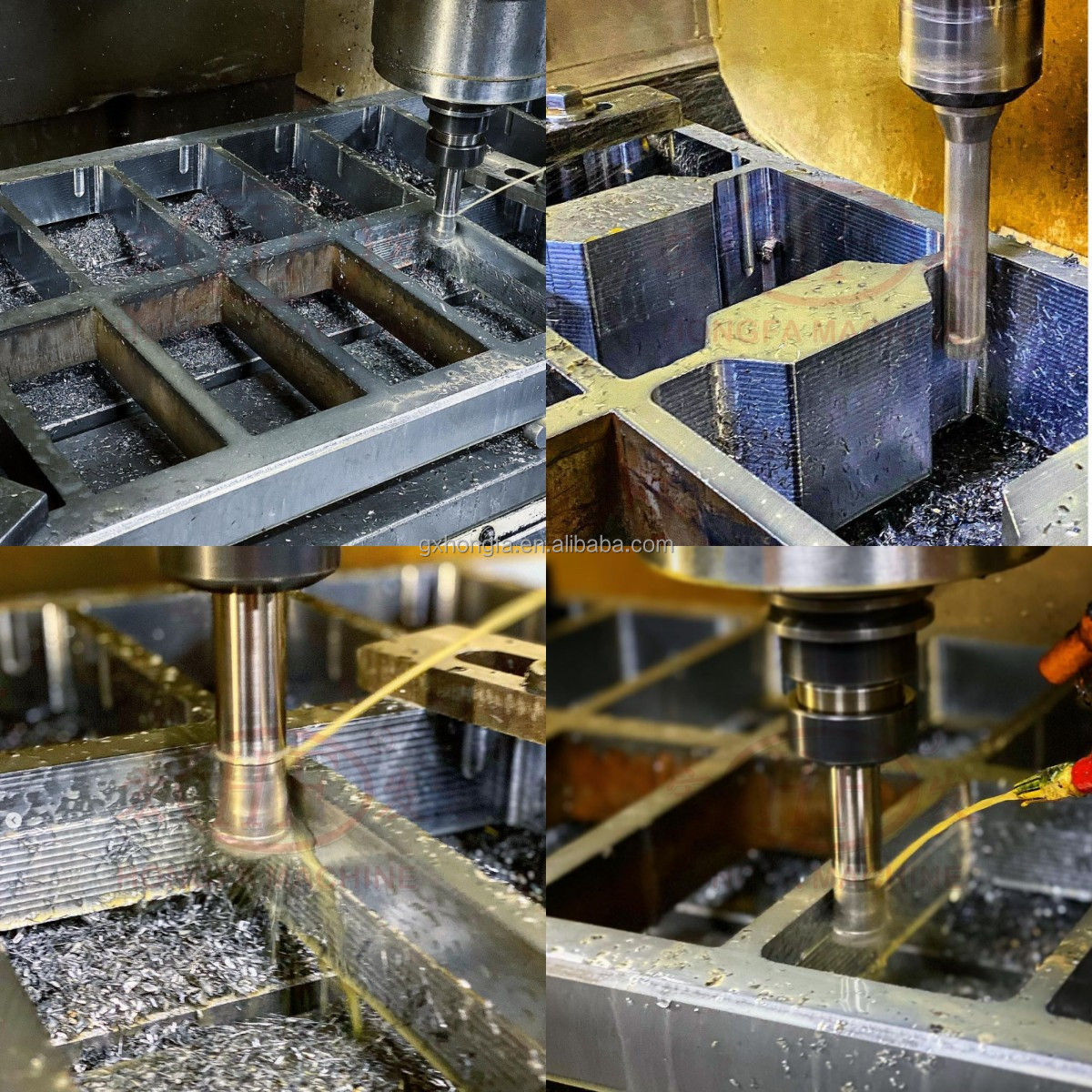

Special-shaped brick molds are precisely produced by CNC machines, using wire cutting

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

block mold Concrete Hollow Block Mold

Quick Details

-

Shaping Mode:

-

CNC wire cutting

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

hongfa

-

Model Number:

-

block mold Concrete Hollow Block Mold

Brick Machine Mold Customized

quality concrete block molds produced by professional mold factories Interlocking Block Mold Interlocking Concrete Blocks Mold

Plastic Concrete Block Molds

We can provide all design ,all factory block machine mold. solid block ,hollow block and paver block mold,curbstone mold.

Our mold use

manganese steel

and go through carbonization heated treatment. promised 200000 times working.

CNC wire cutting machine

Wire EDM is referred to as "wire cutting". It uses electrode wire (molybdenum wire, tungsten-molybdenum wire, etc.) as the tool electrode. Under the action of the pulse power supply, a spark discharge is formed between the tool electrode and the workpiece, and the spark channel instantly generates a large amount of heat, which melts or even vaporizes the surface of the workpiece. . The wire cutting machine makes the electrode wire move along the predetermined trajectory through the movement of the XY pallet and the UV pallet, so as to achieve the purpose of processing the workpiece.

High-heat treatment special technology

( to make the mold more durable and firm)

Finished Product

We can do any size and any design you want according to your drawing or require

1

.

Molds and tamper head plates are manufactured with state of the art milling technology, Highest possible milling and case hardening techniques produce an excellent mold;

2

.

Exact tolerances of the tamper head shoes and the insert allow efficient and precise assembly;

3

.

Adopting High manganese steel with High-heat Treatment Special Technology, the service life can be over 100,000 times;

4

.

The mold fit the deck plate well, low wear and tear, fast distribution of raw material, take off fluently.

Finished Product Applications

Apply Samples

FAQ

Q1:Do you accept OEM for mold?

A1:yes, we accept all OEM design mold,provide design, we will quote you price

Q2: What is the Warranty period of the mold?

A2: Standard mold is 100000 times, heated treatment mold is 200000 times

A2: Standard mold is 100000 times, heated treatment mold is 200000 times

Q3: How many days to make the mold?

A3: depend on design, normally 15-20 days

Q4: How to pay deposit?

A4: 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

A4: 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

Q5: Are your company is the manufacture or trading company?

We are Direct factory,not agent or trading company,and the quality and after-sale services is Guaranteed.

We are Direct factory,not agent or trading company,and the quality and after-sale services is Guaranteed.

Hot Searches