- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China (Mainland)

-

Brand Name:

-

DWM200

-

Single Pulse Energy:

-

130J

-

Pulse Width:

-

0.1-20ms

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

0.2-3mm

-

Dimensions:

-

500*350mm load200kg

-

Weight (KG):

-

350 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts

-

Product name:

-

Mould repair YAG laser welding machine

-

Model Number:

-

DWM200

-

Welding depth:

-

0.1-3mm

-

Pulse Frequency:

-

1-100Hz

-

Cooling Method:

-

Water cooling

-

Observing system:

-

Microscope

-

Application material:

-

stainless steel, steel plate, iron plate and other metal

-

Keywords:

-

gold laser welding machine

-

Application:

-

welding repair machine

Quick Details

-

Max. Output Power:

-

2KW

-

Use:

-

mold repair

-

Laser Source Brand:

-

ZHONGGU

-

Place of Origin:

-

Henan, China (Mainland)

-

Brand Name:

-

DWM200

-

Single Pulse Energy:

-

130J

-

Pulse Width:

-

0.1-20ms

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

0.2-3mm

-

Dimensions:

-

500*350mm load200kg

-

Weight (KG):

-

350 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts

-

Product name:

-

Mould repair YAG laser welding machine

-

Model Number:

-

DWM200

-

Welding depth:

-

0.1-3mm

-

Pulse Frequency:

-

1-100Hz

-

Cooling Method:

-

Water cooling

-

Observing system:

-

Microscope

-

Application material:

-

stainless steel, steel plate, iron plate and other metal

-

Keywords:

-

gold laser welding machine

-

Application:

-

welding repair machine

China Supplier mold repair laser welder metal stainless steel nickel cold gold jewelry yag laser soldering welding machine 200w

|

Model

|

DWM200

|

DWM300

|

DWM400

|

||

|

Max. laser Power

|

200W

|

300W

|

400W

|

||

|

Mono pulse Max power

|

30J

|

60J

|

|

||

|

Laser wavelength

|

1064nm

|

|

|

||

|

Pulse Width

|

0.1-20ms

|

|

|

||

|

Pulse frequency

|

1-100Hz

|

|

|

||

|

Welding penetration

|

≤3mm

|

|

|

||

|

Laser spot size adjusting range

|

0.2mm-3mm

|

|

|

||

|

Positioning accuracy

|

±0.02

|

|

|

||

|

Repeatability

|

±0.01

|

|

|

||

|

Standard configuration working table

|

500*350mm load200kg

|

|

|

||

|

Whole power consumption

|

8KW

|

10KW

|

12KW

|

||

|

Power need

|

220V/single phase/50Hz

|

380V/three phase/50Hz

|

|

||

China Supplier mold repair laser welder metal stainless steel nickel cold gold jewelry yag laser soldering welding machine 200w

Main Features

Main Advantages

1.Using the anti- erosive, high-temperature resistant and ceramic reflector cavity imported,and the life-span of the cavity up to 8-10 years, and that of the Xenon more than 8 million times.

2,Adopting the most advanced auto light-shielding system in the word to prevent the laser from stimulating your eyes.

3,The laser head and the entire optical path can rotate 360 degrees, and it uses the electric lift and drives horizontally.

4.Electric adjustment of the size of the light spot.

5.Both manual welding and automatic mass production are available.

The difference from traditional welding machine.

1. without surface treatment.

2. no consumable.

3. no pollution.

4. easy operation, fast welding speed.

5. Firmer welding.

6. Not many requirements to the operator, only simple training can operate well.

CCD Camera:

Adopts China famous brand CCD camera, LCD screen and red pointer.

CCD camera can photo-shot the welding details and transmit the signal to LCD screen.The welding effect is more clear and intuitive.

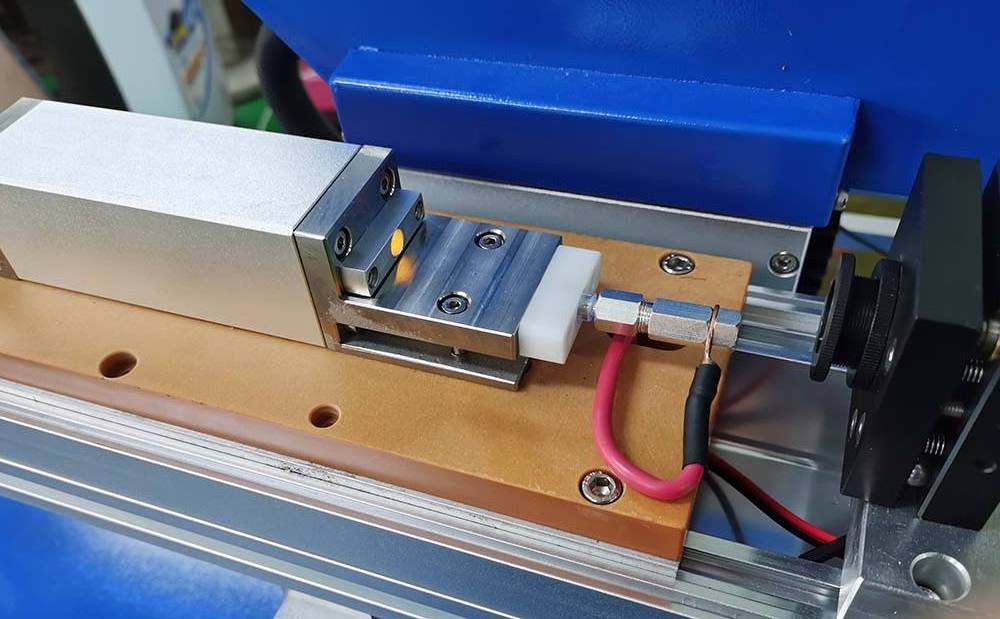

X / Y / Z three-axis mobile work platform:

Electric lifting for the working table,fixed focus more quickly.X/Y platform design sports flexible, able to complete a one-time combination welding curves, straight, single-point and other complex processes.

Laser Head:

The laser head can rotate 360 degress,which is much more convenient for positioning and welding for the special-shaped objects.

Standard comes with 2 high-light camera auxiliary lights, a white CCD auxiliary light, and a blue microscope auxiliary light. The auxiliary lighting uses energy-saving high-light bulbs with clear imaging and good heat dissipation effect, and will not burn the skin for a long time.

Foot Pedal:

Protective foot switch can prevent the switch from being touched by mistake.

BY-LW36 Industrial chiller.Cooling capacity of 3600W, high power cooling effect is more stable.With compressor could cool down laser quickly to ensure that the laser has stable power and efficient and fast operation. Exclusive no water warning and automatic protection system, if there's no water or the water flows in opposite direction, System alerts and stops working,can protect the working life of laser effectively.

Application Industry.

point, circle, arc and square, etc.

Applicable materials.

stainless steel, steel plate, iron plate and other metal and alloy.

China Supplier mold repair laser welder metal stainless steel nickel cold gold jewelry yag laser soldering welding machine 200w

1.Whether you are a dealer or an end user, as long as you are interested in our laser machines and related products, once you contact us, we will arrange a particular professional at your service to help you have a deep understanding of our products or answer your questions on laser products and laser applications.

2.In order to keep open and convenient communication with you, DOWIN Laser integrates sales and service as one and the same responsible person is in charge of your sales and service.

3.On-Time Delivery

After you confirm the order, we will figure out the delivery date according to the model and production schedule.

For general models, we will arrange production in 7 days or so and we will notify you of the exact phase of production process.

4.Production Process:

Machine Case---Mechanical Parts Installation---Electrical Parts Installation--

-Machine Commissioning---Test for at Least 24 Hours --- Nameplate, Logo and Packaging---Shipping

After-Sales Service

*One-year warranty on the whole machine accessories if the machine parts have any problems,we can change the old machine parts to new ones free. *Exceed one year warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you also should pay all the shipping cost. *We offer 24 hours technical support by call,email. *Our technician can give you remote guide online(Skype/MSN/What's app/viber/Tel/Etc) if you have any question. *Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly tell me. *We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine's using and maintenance. 3.Dowin Tech Co.,Ltd supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow: *Training for Control software operation. *Training for normatively turning on/off operation of the machine. *Instruction of technical parameters, as well as their setting ranges. *Basic daily cleaning and maintenance for the machine. *Solutions for common hardware problems. *Training for other questions and technical suggestions during daily production. 4.Training can be processed in the following ways: *Workers of customers can come to our factory to get the most professional hand-by-hand training. *We can send engineers to customers' country and do training for workers in customers' target factory.However,tickets and daily consumption like food and accommodation should be afforded by customers. *Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.

DOWIN LASER

Focus on researching and manufacturing laser machine for 11 years.

Dowin tech Co., Ltd. specializes in R&D and production of various laser equipment,such as laser welding machine,laser cutting machine,laser engraving machine and laser marking machine.Our service support various languages,like English, Spanish,Russian,and so on.Meanwhile,customized equipment are available according to different requirements.Within the laser welding field,Dowinlaser has passed CEqualifications.Which assures high-efficient production and products' reliability.After years of hard work, Dowinlaser's products have made presence in more than 100 Countries such as North America,West Europe, South Asia, South America and Mid East etc.. Facing the chances and challenges of Global Economic Integration,as well as being offered with opportunities of Knowledge Economy Era,brave and passionate, initiatively implement the enterprise management policy: "Scientific Management,Continuous Improvement,Rapid Development,Credit First,Quality First". We aim to be a professional branding,and International suppliers for various industrial solutions.

Q1: I know nothing about this machine, what type of machine should I choose?

A:We will help you choose the suitable machine and share you the solution; you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

Q2: When I got this machine, but I don’t know how to use it. What should I do?

A:A: Operation video and manual will be sent together with machine. Our engineer will do training online. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.

Q3: If some problems happen to this machine, what should I do?

A:We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q4: What’s consumables of laser welding machine?

A: It does not have consumable. It’s very economical and cost effective.

Q5: What’s package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

Q6: What’s delivery time?

A: As per your requirement , we will suggest the suitable machine . The exact delivery time as per your machine. Normal delivery date is 7-10 days after confirm your order and payment.

Q7: What payment terms can you accept?

A: Any payment is possible for us, We support T/T, L/C, VISA, Mastercard payment terms with Alibaba Trade Assurance. etc.

Q8: How is the shipping method?

A: As per your actual address, we can effect shipment by sea, by air, by truck or railway. Also we can send the machine to your office as per your requirement .

Q9: How about quality and reliability?

A: Strong quality control system, each machine must pass 24-72hours vibration test.