- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Betterack

-

Model Number:

-

BT-ASRS

-

Depth:

-

1.5-2.5mm

-

Weight Capacity:

-

500-2000kg/pallet

-

Width:

-

Customized

-

Height:

-

Customized

-

Usage:

-

Warehouse racking

-

Surface treatment:

-

Power coating

-

Dimension:

-

Customized available

-

Scale:

-

Heavy Duty

-

Color:

-

RAL System

-

Weld:

-

Automatic welding

-

Structure:

-

Assembled freely and adjustable

-

Certification:

-

ISO9001:2008,CE

-

Product name:

-

Industrial ASRS automatic storage retrieval system for pallet unit

Quick Details

-

Type:

-

Automated Retrieval

-

Material:

-

Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Betterack

-

Model Number:

-

BT-ASRS

-

Depth:

-

1.5-2.5mm

-

Weight Capacity:

-

500-2000kg/pallet

-

Width:

-

Customized

-

Height:

-

Customized

-

Usage:

-

Warehouse racking

-

Surface treatment:

-

Power coating

-

Dimension:

-

Customized available

-

Scale:

-

Heavy Duty

-

Color:

-

RAL System

-

Weld:

-

Automatic welding

-

Structure:

-

Assembled freely and adjustable

-

Certification:

-

ISO9001:2008,CE

-

Product name:

-

Industrial ASRS automatic storage retrieval system for pallet unit

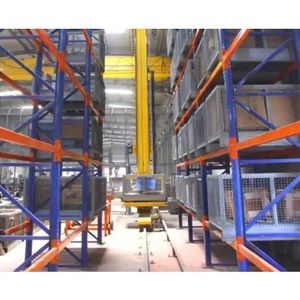

Industrial ASRS automatic storage retrieval system for pallet unit

Automated Storage&Retrieval Systems(AS/RS)

Maximize your storage solution with AS/RS

AS/RS thrive in applications where high volumes of inventory move in-and-out of manufacturing or distribution operations,Storing with AS/RS means accurate,real-time data is kept on inventory-eliminating need for physical inventory inspections and also providing direct access to items at all times,Utilizing AS/RS increases throughput and efficiency,saves space,allows you to use your “air rights” and reduces building costs.

China Supplier New Design Palleting Rack Automatic Storage Systems

The Structure of Automated Storage&Retrieval Systems(AS/RS)

1.Racking

- AS/RS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure.

- Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer.

2. Stacker

- Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; all the way tracing technology by information transferring;

- Electric components are imported from abroad; touching screen interface for easy operation; making manual, semiautomatic, automatic and linkage control come true; used in many situations by combining with other logistics equipment.

- Load Capacity:500-3000kg

- Access Height:5-30m;

- Walking Speed:100-160m/min

3 .Conveying system

Conveying system is usually equipped in the front or back of warehouse for conveying goods here and there, bridging the procedures done by forklifts and stackers by using rolling conveyor or chain conveyor and combining with lifts, rotating devices and other equipments.

4. Controlling system

Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by SIEMENS S7-300 controller can operate all conveyors offline, doing conveying of goods automatically.

Please refer to the attached drawing for details of conveying system

5. WMS System

Hardwares of WMS System: star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods.

Softwares of WMS System:

Operating system: WINDOW 2000X SEVER

Data-base: MS SQL SEVER 2000X

Warehouse management software: WMS

Equipment controlling software: ECS

Bar code management software: RFS

6. Other Related Equipment

Other related equipment include switching cart, rail cart, O/R table, automatic guided vehicle, auto-picking system, electronic label, pallet lift and so on.

Industrial ASRS automatic storage retrieval system for pallet unit

Betterack in Exhibition

Betterack Certification

Production Line Fully Equiped:

- Have 2 Factories

- Punching Machine: 4

- Rolling Production line: 7

- Bending Machine: 5

- Welding Station: 5

- Powder Coating Production Line: 2

Manufacture Experience:

- Over 12 year's Experience For Storage Solution.

- Factory Directly Supply Prodcuts

- With Strict Quality Control For Each Processing

- Rapid Delivery Time

Our Service:

- Professoinal Solution Team Provide Consulting Support

- Customized Design and Project Layout

- Samples Available and Sample Testing Support

- Installation Manual and Drawing Offered

- On Site Inspection Available

Betterack Prodution Process:

Q1 : Do you have any request about the order quantity?

A1 : Any order quantity is accepted. But small order would take more shipping cost;

Q2 : What is delivery time ?

A 2 : It depends on the order quantity and racking types.usually, ordinary order quantity is within 20 days.

Q 3 : What is the term of payment?

A 3 : Generally, 30% T/T down payment and balance before shipping, other terms could be further discussed.

Q 4 : How could you guarantee the products quality?

A 4 : We have experienced workers and strict quality control and the goods will be check whether quality is approved before shipping.

Q5 : H ow could I install the racks?

A 5 : Detail install drawing will be provided to teach you how to install the racks. If needed, we also could provide free engineer to teach you installation. But related cost should be in your charge.