- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

FORSEN

-

Model Number:

-

FS-3+3

-

Type:

-

Paste

-

Color:

-

Black/red/grey

-

Application:

-

sealing

-

Working temperature:

-

-70 ~ +280 ℃

-

Certificate:

-

TS16949

-

Quality:

-

Top

-

Shelf life:

-

12 months

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

silicone gasket maker

-

MF:

-

mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

FORSEN

-

Model Number:

-

FS-3+3

-

Type:

-

Paste

-

Color:

-

Black/red/grey

-

Application:

-

sealing

-

Working temperature:

-

-70 ~ +280 ℃

-

Certificate:

-

TS16949

-

Quality:

-

Top

-

Shelf life:

-

12 months

RTV silicone gasket maker Free Super Glue

is a one part RTV silicone that remains flexible and withstands high vibration. Designed

primarily for flange sealing with excellent oil resistance on rigid flange sealing, for example on

transmissions and cast metal housings.

Forms a high quality gasket that seals the space between matched parts to prevent leakage of

automotive fluids and gases.

It meets manufacturers ’ specifications for original equipment.

Features:

- Seals joined parts in automotive systems - prevents leakage of antifreeze, air, oil and transmission fluid

- Meets manufacturers' warranty requirements

- Resists oil better than other silicone gasket makers

- Won't interfere with sensors

- Won't corrode

- Resists vibration

- Low odor

Specs:

- Tack-free cure (time required to dry past tacky state): 30 minutes

- Full cure (time required to reach full set): 24 hours

- Temperature range (endurance limits of the gasket maker): -75 F to 625 F

- Ideal gap-filling capacity (gap sizes in which gasket maker performs best): 0.001" to 0.125"

- Maximum gap-filling capacity (maximum gap size between joined parts): 0.240"

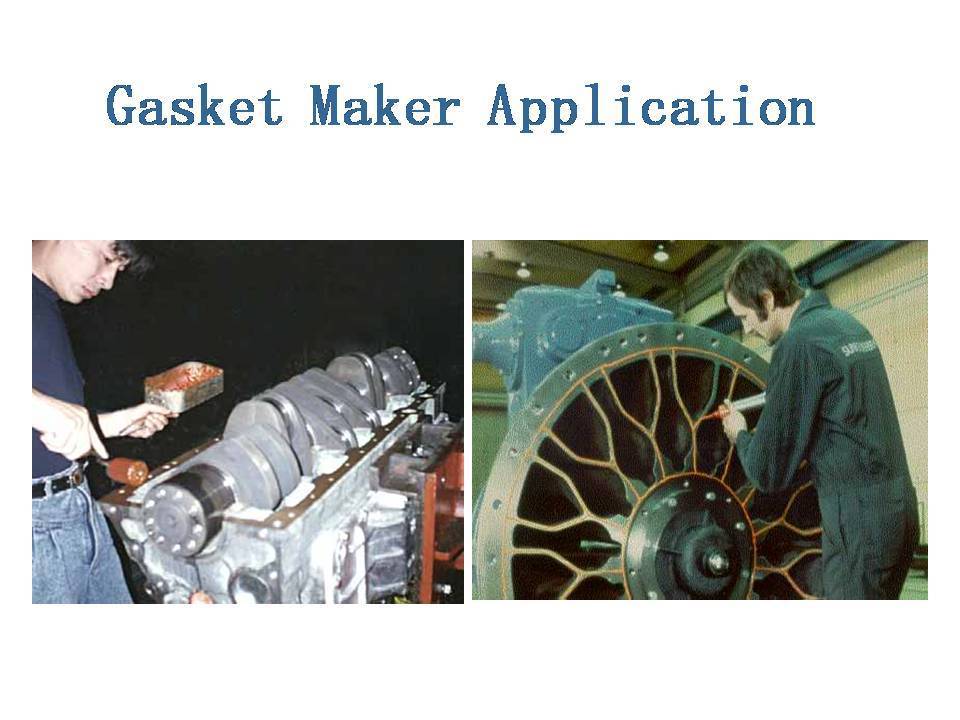

Applications:

Valve covers, oil pans, timing covers, water pumps and thermostat housings

Applied as a gel to just one surface of the parts to be joined, silicone gasket maker forms a seal between them, keeping out contaminants. Silicone gasket maker resists oil and shop fluids, vibration, heat, and flexing of parts, replacing many conventional gaskets. Parts joined by this silicone gasket maker can easily be removed. The old gasket material comes off effortlessly, simplifying future disassembly and reassembly.

This product is OEM specified: It is approved to meet specifications of original equipment manufacturers .

Directions for use :

1. For best performance bond surfaces should be clean and free from grease.

2. Moisture curing begins immediately after the product is exposed to the atmosphere, therefore parts to be assembled should be mated within a few minutes after the product is dispensed.

3. The bond should be allowed to cure (e.g. seven days), before subjecting to heavy service loads.

4. Excess material can be easily wiped away with non-polar solvents .

Technical data:

As Supplied – tested at 23 °C ±2 °C , RH50%±5%:

Aspect: Paste

Specific Gravity: 1.15~1.25

Skinning Time, min: 5~15

Application Temperature, °C : +5 to +40

Drop Degree, MM : ≤1

Extrusion Ability, mL/Min: ≥ 300

As Supplied – tested at 23 °C ±2 °C , RH50%±5% 7 days :

Hardness Shore A: 20~60 ASTM C 661

Tensile Strength, MPa: ≥3.0 ASTM C 1135

Elongation at Breaks, %: ≥ 2 00 ASTM D638

Volatility Content, %: ≤35 EPA -24

Depth of Curing, 24H, MM ≥3 ASTM C1184-05

Depth of Curing, 7D, MM ≥6 ASTM C1184-05

85g per tube /blister , 12pcs / inner carton ,144 pcs / master carton

85g per tube./ blister ,20 pcs /inner carton , 120 pcs / master carton

Inner carton display: