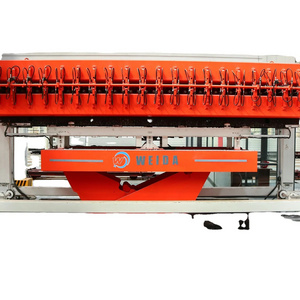

The cutting cart will take the block to

horizontal

cutting machine, vertical cutting

machine

, two sides cutting

machine.

Then remove waste material on the block.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

Wide range and Customize

-

Processing:

-

AAC Block Production Line

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220/380/440

-

Marketing Type:

-

Hot product 2024

-

Weight (KG):

-

980000 kg

-

Capacity range for AAC block:

-

50000m3 to 500,000m3 per year

-

After Warranty Service:

-

Video Technical Support Online Support

-

Advantage:

-

Advanced design

-

Block Type:

-

Lightweight aerate autoclaved block

-

PLC brand:

-

Siemens or Customize

-

Pre-sale Consulting:

-

Available

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC), Autoclaved aerated concrete panel

-

Brick Raw Material:

-

Sand, Fly ash, etc

-

Production Capacity (Pieces/8 hours):

-

50000-500000m3/year

-

Brick size:

-

Wide range and Customize

-

Processing:

-

AAC Block Production Line

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220/380/440

-

Marketing Type:

-

Hot product 2024

-

Weight (KG):

-

980000 kg

-

Capacity range for AAC block:

-

50000m3 to 500,000m3 per year

-

After Warranty Service:

-

Video Technical Support Online Support

-

Advantage:

-

Advanced design

-

Block Type:

-

Lightweight aerate autoclaved block

-

PLC brand:

-

Siemens or Customize

-

Pre-sale Consulting:

-

Available

Product Specifications

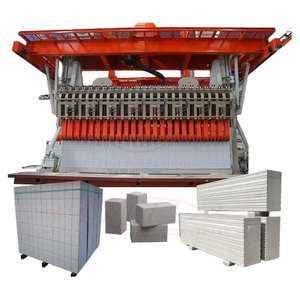

Advanced Manufacturing Technique

1.Raw material dealing

Put the fly ash or sand into the ball mill to mill via the conveyor belt.

After milling, put the slurry into the slurry storage tank by

pump.

2.Batching, mixing and pouring process

The lime, cement will be conveyed by conveyor to the dry powder measure scale, to scale separately.

The lime, cement will be conveyed by conveyor to the dry powder measure scale, to scale separately.

The slurry conveyed by slurry pump then to the automatic scale;

the power and slurry put into the mixer, pouring into the mould.

3.Curing process

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃.

3.Curing process

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃.

After 2-3 hours curing,the blocks become solid.

4.Cutting process

Using reversal crane carry the mould and block to cutting cart.

Then demould the block.

5.Autoclaved

Crane carry the block to the front of autoclave, dragger will drag steam trolley into autoclave to steam.

It need 10-12 hours.

6.Finished block dealing

Separting machine separate the block layer by layer.

7.Packaging

Clamping machine carry the finished product to package line on wooden pallets.

After packaged, forklift transport the finished products to piled yard.

Advantages of AAC Block machine & production line

1) Advanced technology

The machine adopts Yitong process to realize the green body turning in the air, the fixed-step cutting of the green body walking, the hydraulic lifting and conveying, the bottom turning in the air, and the defoaming treatment of the steam drum.

2) Advanced design

1. It can realize the mixed grinding to prepare the cementitious material and effectively improve the pouring stability; the flow-tube type pouring stirring can shorten the stirring time and greatly improve the uniformity of stirring.

2. Raw material processing.

Can realize the hydrothermal ball milling process and improve the stability of fly ash and mortar.

3. Staggered batching process.

The batching building is divided into two and staggered. It simplifies the layout of equipment and building structure, and meets the requirements of staff space and equipment layout.

2) Advanced design

1. It can realize the mixed grinding to prepare the cementitious material and effectively improve the pouring stability; the flow-tube type pouring stirring can shorten the stirring time and greatly improve the uniformity of stirring.

2. Raw material processing.

Can realize the hydrothermal ball milling process and improve the stability of fly ash and mortar.

3. Staggered batching process.

The batching building is divided into two and staggered. It simplifies the layout of equipment and building structure, and meets the requirements of staff space and equipment layout.

Product Applications

What is AAC Block?

Autoclaved Aerated Concrete is a Lightweight, Load-bearing, High-insulating, Durable building product,

which is produced in a wide range of sizes and strengths.

AAC Blocks is lightweight and compare to the red bricks AAC blocks are three times lighter.

Full Automatic Aerated Autoclave Concrete AAC Block Making Cutting Machine Equipment Plant Production Line For Manufacturing

|

Advantages of AAC block

|

|

|

|

Light

weight

|

The weight of AAC block is the same as 1/3 of clay brick or red brick and 1/5 common concrete, density is usually 400-700kg/m3,(according the market in produce ).

So use the Light brick can reduce the weight of the build more, and also reduce the beam of roof and pillar press. It can save the material and cost, and also fighting shaking. |

|

|

Keeping temperature

|

It has many porous, the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world.

Also many kinds raw material, have lowest waste. Main Materials:coal ash sand waste mine material coal stone, stone dust and other silicon materials. |

|

|

Cost saving

|

Being lightweight AAC reduction in steel 27%, cement 20% structural cost saving. Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an overall mortar saving 66%.

|

|

|

Earthquake resistant

|

It has been proven to withstand wind loads of 5 tropical storms. The same building structure,improve double aseismatic ability than the brick level.

|

|

|

Hight strength

|

Hight strength can reach 40KG/square centimeters (about 4.0Mpa). Sand tybe AAC block normally is 3.8-4.2Mpa, Fly ash tybe AAC block is about 3.0-3.5Mpa.

|

|

|

Water barrier & Fireproofing

|

Its water barrier properties are further enhanced by adding silicone based additives.

|

|

|

Easy to install

|

Simple and convenient installation

|

|

Raw material for AAC block

Our service & strength

Our Service

Pre-sales Service

* Inquiry and consulting support.

* Solution support.

* View our Factory.

After-sales Service

* Training how to install the machine, training how to use the machine, English instructions available.

* Engineers available to service machinery overseas.

2.Our company has set up office in Vietnam,Indonesia,South Africa and sale service station in nanning guangxi province and will ensure the matericals rapid and timely service.

* Inquiry and consulting support.

* Solution support.

* View our Factory.

After-sales Service

* Training how to install the machine, training how to use the machine, English instructions available.

* Engineers available to service machinery overseas.

Packing & Delivery

1.We have successfully exported and established more than 100 sets of AAC Block Production line in domestic and overseas. So we have many type of business model in other countries.

2.Our company has set up office in Vietnam,Indonesia,South Africa and sale service station in nanning guangxi province and will ensure the matericals rapid and timely service.

Packing and Shipping

Hot Searches