- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TPX6113/2

-

Voltage:

-

Customer's Requirement

-

Dimension(L*W*H):

-

7030*4665*3800MM

-

Weight:

-

28000KG

-

Power:

-

15KW

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

20sets per month

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

KAKU

-

Model Number:

-

TPX6113/2

-

Voltage:

-

Customer's Requirement

-

Dimension(L*W*H):

-

7030*4665*3800MM

-

Weight:

-

28000KG

-

Power:

-

15KW

-

Certification:

-

ISO9001:2008

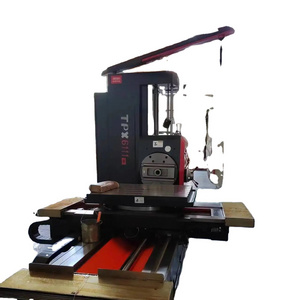

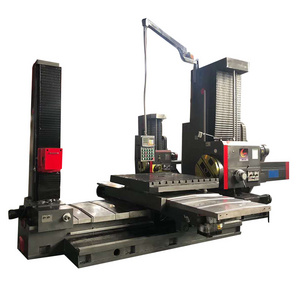

TPX6113/2 TPX6113D DRO Horizontal Boring and Milling Machine

Features of TX6113C/2 TX6113D DRO Horizontal Boring and Milling Machine

1. TPX6113C/2 TPX6113D DRO Horizontal Boring and Milling Machine is of table-type layout, with column mounted on the bed and a side spindle head; guideway of the lower saddle is of cross structure.

2. A manual optical positioning device for at every 4x90° positioning of the table is provided for some models.

3. Some models positioned by a circular grating scale may make the table indexing continuously 360°;

4. Machine bed with larger specifications is added with integral auxiliary guideway;

5. Spindle system consists of three-layer structure, facing head spindle, hollow spindle and boring spindle;

6. The boring spindle is of high quality nitride steel 38CrMoAIA; the hollow spindle is of high quality alloy steel; the spindle is of high structure rigidity and accuracy;

7. The spindle with disk spring clamping and hydraulic unclamping makes tool handling easy;

8. Control system is provided with Mitsubishi PLC DRO unit and measuring elements are from SINO or NEWALL;

Applications of TPX6113C/2 TPX6113D DRO Horizontal Boring and Milling Machine

Fortune Pacific TX6113C/2 TX6113D DRO Horizontal Boring and Milling Machine are used for rough and finishing boring and milling large-sized and medium-sized parts. Table is provided with DRO unit with continuous indexing for 360° and can meet needs of in-line boring of parts with the table being turned for 180° and multi-point machining. Machine is provided with integrated guideway with good rigidity and stable accuracy. Each axis is clamped hydraulically. The spindle with disk spring clamping and hydraulic unclamping makes tool handling easy. Machine is provided with PLC, X, Y, Z and B axes are provided with grating DRO unit, and reading accuracy is 0.005mm.

Technical parameters of TX6113C/2 TX6113D DRO Horizontal Boring and Milling Machine

1. Technical support online service provided.

2. Technical files service provided.

3. Machine operation video provided.

4. On-site training service provided.

5.Spare parts replacement and repair service provided.

6. All of the questions will be replied within 8 hours.

7. If you need to develop products with your own specification, we can help you to work it out.

8. Always be honest, never lie to customer, and never declare anything we don't have.