- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1.3 KG

-

Dimension(L*W*H):

-

590*55*55mm ( dimension for reference)

-

Hollow fiber:

-

Polysulfone

-

Operating temperature:

-

normal temperature

-

Purity:

-

84%-95%

-

Concentration:

-

85%-95%

-

Size:

-

590*55*55mm

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

WOBO

-

Production Rate:

-

99.8%, 99.8%

-

Weight:

-

1.3 KG

-

Dimension(L*W*H):

-

590*55*55mm ( dimension for reference)

-

Hollow fiber:

-

Polysulfone

-

Operating temperature:

-

normal temperature

-

Purity:

-

84%-95%

-

Concentration:

-

85%-95%

-

Size:

-

590*55*55mm

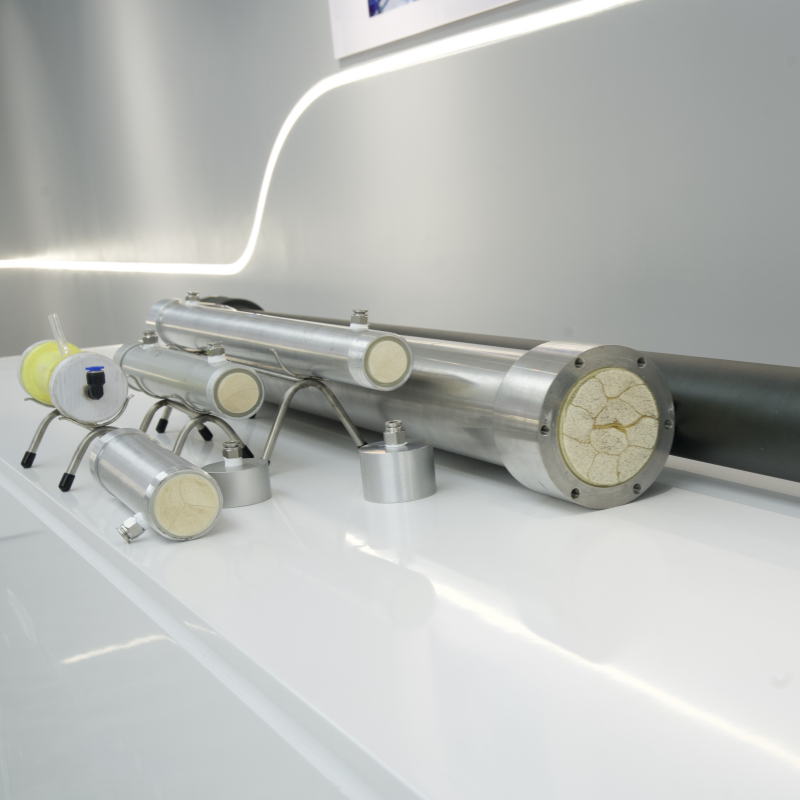

Air Drying System Hollow Fiber Air Dehumidification Membrane

Advanced Moisture Separation Membrane Dehumidification 4040 Membrane for Powder Product Drying

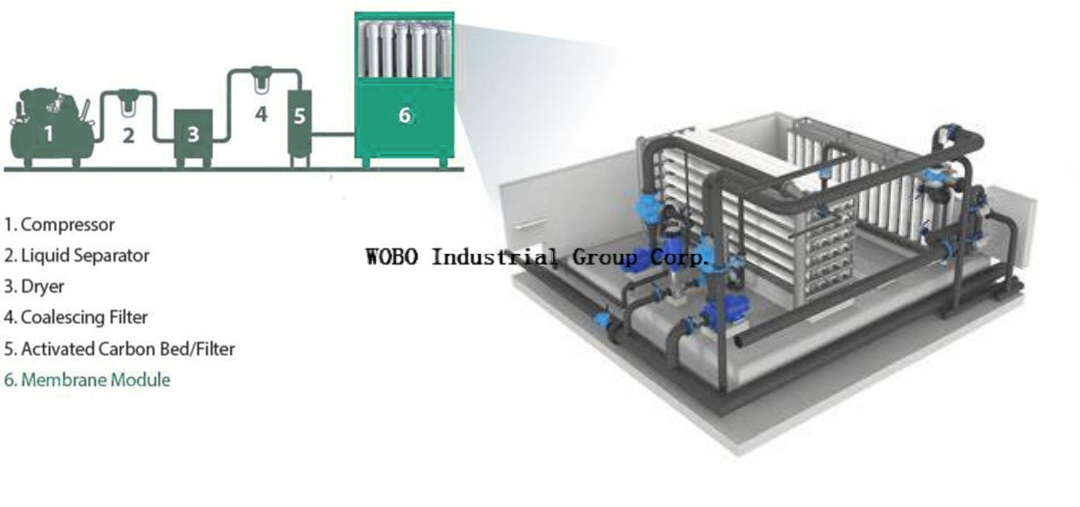

Technical Principle

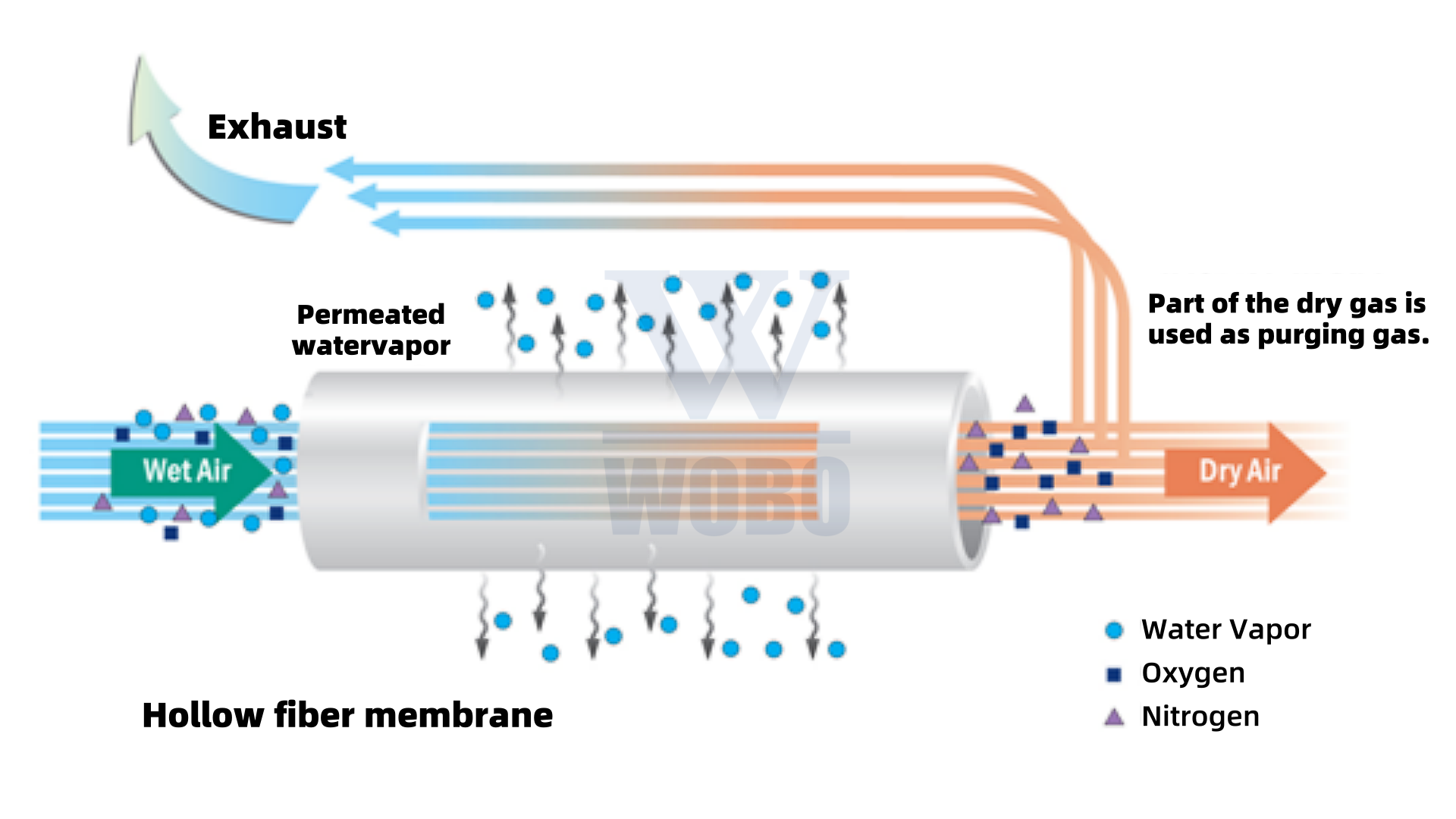

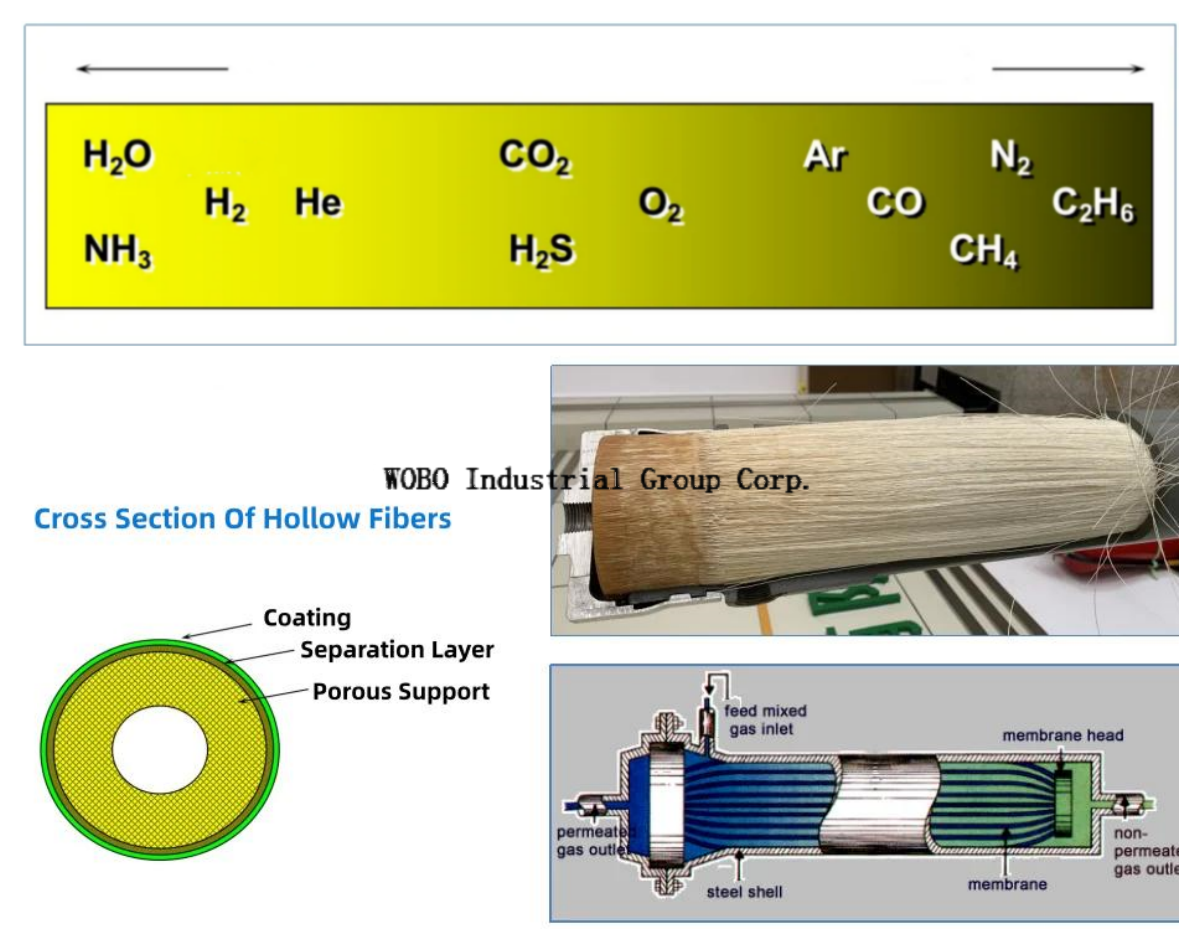

The working principle of compressed air membrane dehydration is as follows: when water vapor passes through the hollow fiber membrane, water molecules permeate at a faster rate. Under the pressure difference, water vapor (H2O) permeates to the permeable side, while other gas molecules such as O2, N2, CO2, and He in the air remain on the non-permeable side and reach the outlet under pressure, thereby achieving the purpose of dehydration and drying.

Compared to traditional methods, membrane dehydration technology offers several advantages including efficiency, energy saving, cleanliness, simplicity of equipment, ease of operation, no pollution, maintenance-free, and long lifespan. The membrane dehydration device is a compressed air dehydration membrane separation device assembled from special hollow fiber membranes made of polymer materials. The processing capacity of the equipment is flexible and adjustable, allowing for different blow ratios of sweep gas to adjust the dew point of the product gas according to different applications, and it can replace the use of refrigerated dryers.

The characteristics of membrane dehydration technology are as follows:

1. Energy-saving: It operates using the pressure of compressed air itself, eliminating the need for additional energy sources.

2. Clean product gas: It produces clean gas without any pollution, making it environmentally friendly.

3. Low operating cost: It doesn't require regeneration, and the equipment is simple to operate, resulting in low running costs.

4. Low maintenance: With no movable parts, it is noise-free, maintenance-free, and has a long lifespan.

5. Cost-effective for small processing capacities: It offers advantages in equipment investment for smaller processing capacities.

|

Method

|

Desiccant

|

Refrigeration

|

Membrane

|

|

Dehumidifying Performance

|

High

|

Low

|

Mid-High

|

|

Dew Point

|

-30--57℃

|

0--20℃

|

-20--40℃

|

|

Installation Area

|

Large

|

Large

|

Small

|

|

Maintenance Requirement

|

Middle

|

Middle

|

Easy

|

|

Device Size

|

Small-Large

|

Small-Large

|

Small-Middle

|

|

Components

|

Tower / Tank / Heat Exchanger

|

Refrigerant / Condenser / Heat Exchanger

|

Separation Membrane/Filter

|

Membrane Separation Process

Detailed Photos

Project Case

Product Application Field

Hot Searches