- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FUSION

-

Name of the carding machine:

-

Polyester fiber carding machine

-

Suitable raw Material:

-

Cotton / Fiber/ Wool/ PP

-

Working principle:

-

Roller's interaction and rolling

-

Function:

-

Opening cotton fiber

-

Final product:

-

Fluffy Cotton pillows siliconized fiber opening machine

-

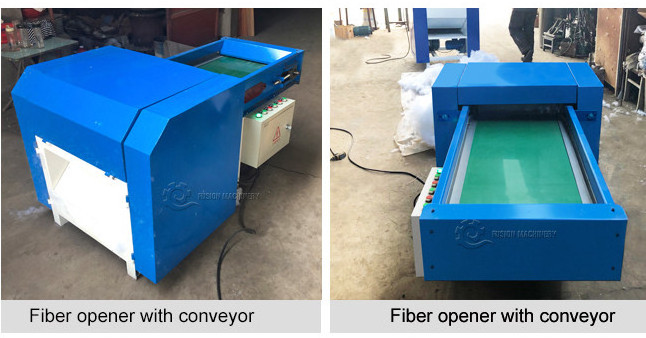

Conveyor:

-

Optional for clients & customize service

-

Related machine:

-

Cotton filling machine & Pearl ball making machine

-

Production Capacity:

-

99.87%

-

Application:

-

memory card making machine fiber

-

Control:

-

Electric control box

Quick Details

-

Weight (KG):

-

260

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FUSION

-

Name of the carding machine:

-

Polyester fiber carding machine

-

Suitable raw Material:

-

Cotton / Fiber/ Wool/ PP

-

Working principle:

-

Roller's interaction and rolling

-

Function:

-

Opening cotton fiber

-

Final product:

-

Fluffy Cotton pillows siliconized fiber opening machine

-

Conveyor:

-

Optional for clients & customize service

-

Related machine:

-

Cotton filling machine & Pearl ball making machine

-

Production Capacity:

-

99.87%

-

Application:

-

memory card making machine fiber

-

Control:

-

Electric control box

Ce Approved Industrial polyester pearl cotton fiber wool fusion carding machine for sale / fiber opening machinery wool carding equipment polyester fiber automatic weighing bale opening machine

1. Introduction of the fiber carding cotton opener machine:

Cotton Carding Machines used for uniformly opening and loosening such 0.7D-15D fiber cotton as PP cotton , screw cotton , doll cotton , ordinary hollow cotton and down cotton . One-time opening rate can reach 100%.

Therefore, the machine is suitable for using in the toy factory, sofa factory, bedding factory, home textiles factory and clothing factory, and is also used for opening and loosening the used wool, the used woolen sweater, the used cotton quilt, the macerated fabric and the polyester wadding tailings, etc.

Feature

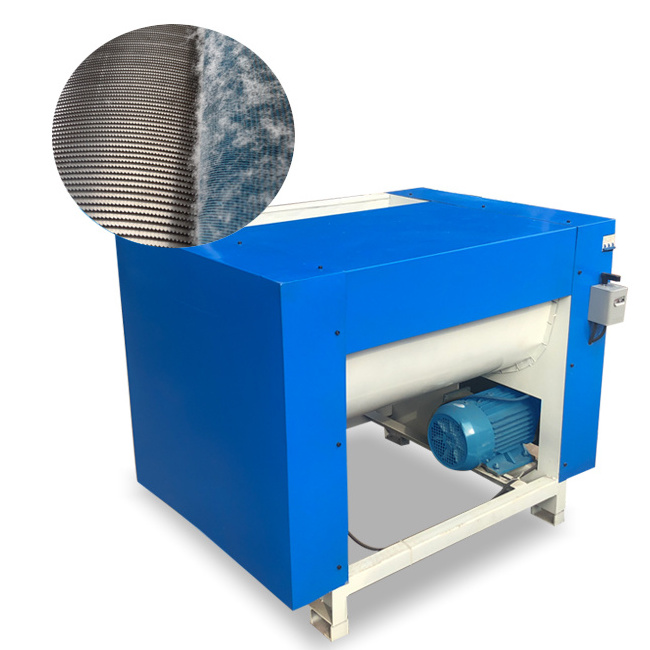

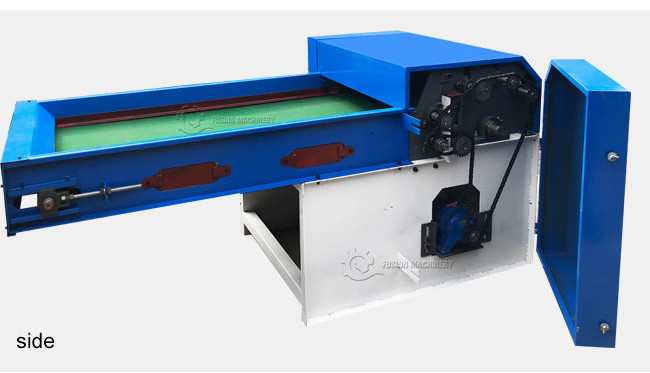

1. The machine can loose n and tidy the raw cotton for more than ten thousand times from front to back at a high speed of 1400r/m in the differential rotation achieved by the big pin roll and many small pin rolls, which can achieve the purpose of opening and loosening without damaging the raw cotton.

2. For the pin rolls, the seamless steel tube is used for grooving. The imported alloy steel rack special for combing in cotton spinning is wound. The high-speed balancing treatment has been made on the main roller. The error between the left and the right is only 0.1-1 gram , which can ensure more smooth and steady transmission of the machine. Moreover, the service life of the whole machine is longer, and the maintenance cost is lower.

3. The compound industrial belt can be used for automatically feeding cotton, which has advantage of easy and safe operation, longer continuous operation and lower maintenance rate.

4 . Cotton feeding and discharging are automatically controlled by electronic infrared ray, and integrated electronic box control is available for overload, and high temperature protection.

5. The machine is made of national standard steel plate by professional sheet metal stamping to provide firm and durable property, is finished by electrodusting and stoving varnish with more service life than common coating, and without paint removing and color change.

2. Technical parameters:

| Model | Capacity | Power | Macine size | Net Weight |

| ZSKM-100 | 50 kg/h | 1.5 kw | 800*500*750 mm | 155 kg |

| ZSKM-150 | 90 kg/h | 2.2 kw | 1000*500*780 mm | 185 kg |

| ZSKM-200 | 120-150 kg/h | 3 kw | 900*800*850 mm | 260 kg |

| ZSKM-300 | 200-230 kg/h | 4 kw | 1200*850*950 mm | 360 kg |

| ZSKM-300A | 200-230 kg/h | 4 kw | 1200*2200*1000 mm | 460 kg |

| ZSKM-300B | 300-350 kg/h | 5.5 kw | 1200*2200*1000 mm | 520 kg |

Less maintenence disign , prevent fibre come into the gaps and bearing. Customer do not need to clean everyday and prevent stuck if rubbish too much.

1: All covered design. Each moving part are not able to touch.

2: Operation plate is 24V/ safety voltage (Safety voltage: not more than 36V).

3: Fiber jamed preventing design. To prevent fiber jamed and main parts to be broken in case wrong operation.

4: Baking painting. Use baking painting, the painting will hard to get off when machine running long time. Machine looks like new after long time using.

5: Famous brand motor. Use local famous brand Dongguan motor, 99% complete carding polyester fibre.

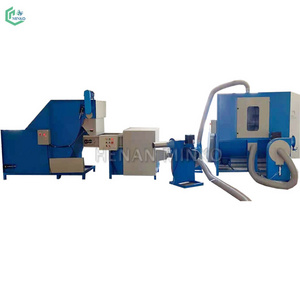

The process: 1. Cotton opening machine; 2. Ball fiber machine.

After PP cotton being opened, then it can process to ball shape products. Features of Ball Fiber Machine/Ball Fiber Making Machine

1.

High production 120-180kg/h, only need 1-2 workers.

2.

Cotton break and molding automatically; Machine with electrical cluth control system.

3.

Ball size can be adjustable from 0.2g to 3g

Application scope:

Cotton opener is used for two-dimensional and three-dimensional screw cotton, PP cotton, doll cotton, and ordinary hollow cotton to be uniformly spread and fluffy.

As long as it is opened once, it is suitable for toy factories, sofa factories, bedding factories, and home textile factories.

Our machine is the pre processing machine for cotton, fiber, PP and other raw material.

After process, All the cotton and fiber can be filled in pillow, toy and different kinds products.

The opening machine is professional on furniture factory, home textile factory, toy factory, cotton per process machine. If our machine can make your work easier, please contact with us freely.

Related product : Cotton filling macine and Pearl cotton ball machine :

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou,etc. We also accept land, air, sea transport and international multimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand, the UAE, Poland, Spain, Germany, India, etc.

1. We always welcome customers to visit our manufacturing factory and get to know more about us.

2. Customers can see all the manufacturing workflows when they visit our factory. you can contact with online besides offline:

Tel/ Wechat/ WhatsAPP/ iMessages: +86 155 0374 7612

3. We also send engineers to the customer's place to help with the installation!