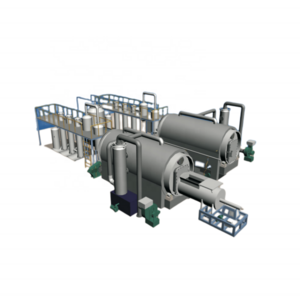

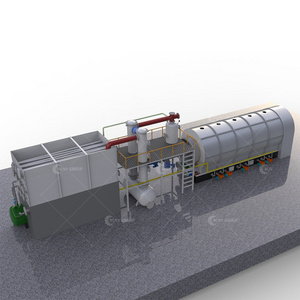

This solution is a high-grade waste pyrolysis plant with advanced dedusting system and smell disposal system.

Waste tyre and plastic are treated inside the pyrolysis reactor at high temperature condition, and pyrolysis occurs while the reactor continuouly rotating. The pyrolysis gas is buffered and purified at the oil gas outlet and enters the three-step cooling system to condense into liquid fuel oil, then collected into the temporary storage tank and pumped by the pump into the transfer tank for further refining and deep processing to become a clear and transparent quality fuel oil (non-standard diesel)

After the solution, the crude carbon black is discharged from the slag outlet through an automatic elevator and then lifted into a magnetic separator to separate the capillary iron contained in the carbon black and then packaged.

The flammable non-condensable gas is purified by the smell disposal system before recycled to furnace as the auxiliary heating energy in order to keep factory from bad smell. The smoked is processed with pulse dedusting system. No sewage is generated, and there is also no black smoke after dust removal. The cooling system continuously condenses high-temperature oil gas, and cooling water is also circulating, the pyrolysis reactor is heated with the fuel produced by the pyrolysis plant.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

32000 KG

Quick Details

-

Place of Origin:

-

HEN

-

Brand Name:

-

DETUO

-

Equipment Capacity:

-

15T/day

-

Weight (KG):

-

32000 KG

Products Description

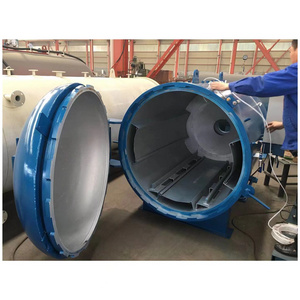

Batch pyroplysis plant

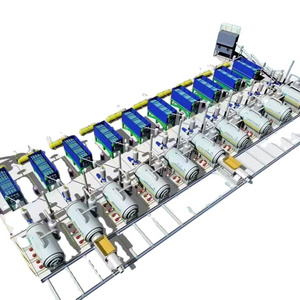

Details Images

Hot Searches