- Product Details

- {{item.text}}

Quick Details

-

Power:

-

22-240kw

-

Weight:

-

1 KG

-

Dimension(L*W*H):

-

17000*1300*2200mm

-

Product name:

-

animal feed processing machine

-

Material:

-

Stainless Stell

-

Color:

-

Silver

-

Output:

-

100-500kg/h

-

After-sales Service:

-

Service Machinery Overseas

-

Installation:

-

70kw

-

Model:

-

TSE65/70/85

-

Need workers:

-

2-3 workers

-

Whatsapp:

-

0086 15689697598

-

Keywords:

-

animal feed processing machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sunard(fish feed)

-

Voltage:

-

380v/ 50 Hz, etc

-

Power:

-

22-240kw

-

Weight:

-

1 KG

-

Dimension(L*W*H):

-

17000*1300*2200mm

-

Product name:

-

animal feed processing machine

-

Material:

-

Stainless Stell

-

Color:

-

Silver

-

Output:

-

100-500kg/h

-

After-sales Service:

-

Service Machinery Overseas

-

Installation:

-

70kw

-

Model:

-

TSE65/70/85

-

Need workers:

-

2-3 workers

-

Whatsapp:

-

0086 15689697598

-

Keywords:

-

animal feed processing machine

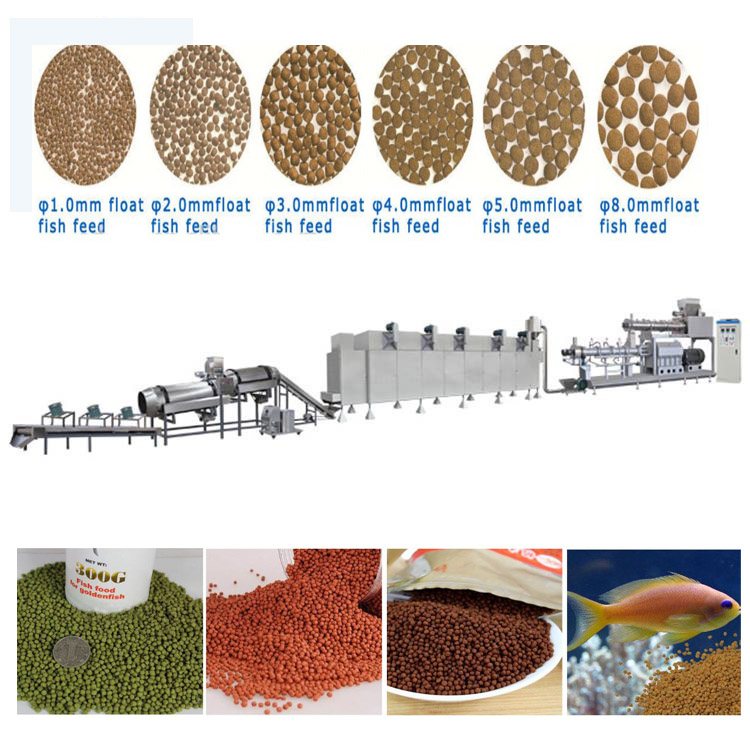

Floating fish food pellet machine / animal feed processing machine /

animal feed processing plant

1.1 Fish feed processing machine/fish feed making machine/pet food making machine Introduction

Animal feed processing machine is used to produce different kinds of pet food, floating fish feed, and sinking feed. It works with simple opeation, accurate parameter control. The products can be finished in the stipulated temperature, pressure, humidity and time. Owing to the reasonable design,special materials, the staility, repairs can be guaranteed and ensured. The various shape and taste must meet the different requirements of pet food.

1.2 Processing Line Description of Floating fish food pellet machine

Mixer---Screw Conveyor---Twin-screw Extruder---Air conveyor---Dryer---Flavoring line---Cooling machine

Twin screw extruder---Air conveyor--Dryer--Flavoring machine---Cooling machine

1.3 Voltage of Factory supply fish food pellet processing making extruder fish feed machine

Three phases: 380V/50Hz, Single phase: 220V/50Hz. we can make it according to customers' Local voltage according to different countries.

1.4 Raw Material of Factory supply fish food pellet processing making extruder fish feed machine

Adopts c o rn powder/rice powder/wheat flour/meat as raw materials meanwhile mixing with water and oil.

1.5 Capacity of animal feed processing machine

100kg/h - 3500kg/h(Floating fish food pellet machine / animal feed processing machine /animal feed processing plant )

1.6 Samples of fish feed/floating fish feed/pet food

|

Parameter of feed processing machines |

|||

|

Model |

TSE-65-III |

TSE-70 |

TSE-85 |

|

Installed capacity(kw) |

70 |

105 |

205 |

|

Real power(kw/h) |

50 |

75 |

150 |

|

Output(kg/h) |

100-150 |

200-260 |

400-500 |

|

Dimension(mm) |

17000*1300*2200 |

20000*1500*2200 |

30000*1500*2600 |

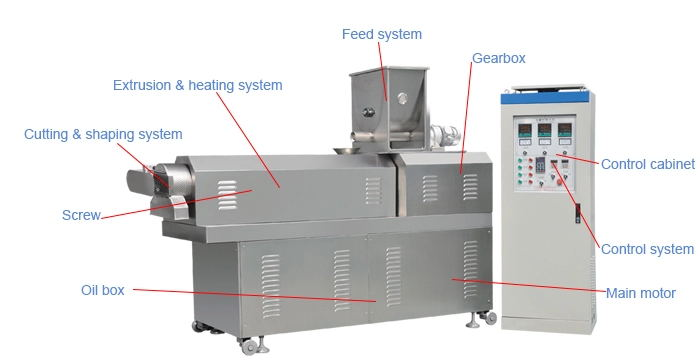

2.1 Twin-screw extruder

1.The main extruder adopts

frequency speed controlling

with high automation.

2.The screws are made of the

stainless steel and special craft

, which has the advantage of durable usage, high pressure,and longer life.

3.The

forced lubrication system

,which can guarantee the equipment transmission life longer.

4.

Auto-temperature control system and self-cleaning

,which makes it more convenient.

5.It has the widest range of applications and can produce different products with

different equipment and models.

2.2 Multi-layer Dryer

1.We have

four types of dryers

,

which includes fuel ovens, gas ovens, electric ovens, and high temperature inflated ovens (used to produce corn flakes).

2.The electric oven has three layers of five meters / five layers of five meters / five layers of eight meters / seven layers of eight meters / seven layers of eleven meters, etc.,

each layer has electric heating tubes

,

the purpose is to be more evenly heated.

3.Dryer is compact, has small dry area and a largesuperficial area. It also features

small scale of heat elimination and high thermal effciency.

4.Mesh belt conveyors and thermal insulation boards all use

stainless steel

material

,

making the equipment clean and sanitary.

5. The speed of mesh belt conveyor is

adjustable

,

the drying period for food in the oven can be adjusted.

6. The

automatic temperature control system

makes it possible to set the temperature according to your needs.

2.3 Flavoring line

1.Spraying the oil in the roller.

2.The inside turning container is very sanitary because of adopting the stainless steel material .

3. Material touching food is stainless steel.

4. The inside of the roller is also uneven , the main purpose is to more evenly season .