- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

junyu0087

-

Product Name:

-

Injection Mould parts,metal stamping mold parts

-

Material:

-

all knids of steel and carbide

-

Tolerance:

-

0.001mm-0.05mm

-

Delivery Time:

-

7-8 Working Days

-

Surface treatment:

-

TiC/ZrN/CrN/MoS2/TiAlN/TiN-AlN/CNx/DLC Polishing

-

Advantage:

-

Professional Team Skilled Technology Fast Delivery Unlimited Quantity

-

MOQ:

-

1 Pcs

-

Certification:

-

ISO9001

-

Application:

-

Machinery Parts ,mold

-

Type:

-

Mold Tool

Quick Details

-

Shaping Mode:

-

Grinding, wire cutting, EDM ,cnc machining,cnc turning,cnc Milling.

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

junyu

-

Model Number:

-

junyu0087

-

Product Name:

-

Injection Mould parts,metal stamping mold parts

-

Material:

-

all knids of steel and carbide

-

Tolerance:

-

0.001mm-0.05mm

-

Delivery Time:

-

7-8 Working Days

-

Surface treatment:

-

TiC/ZrN/CrN/MoS2/TiAlN/TiN-AlN/CNx/DLC Polishing

-

Advantage:

-

Professional Team Skilled Technology Fast Delivery Unlimited Quantity

-

MOQ:

-

1 Pcs

-

Certification:

-

ISO9001

-

Application:

-

Machinery Parts ,mold

-

Type:

-

Mold Tool

PEOFESSIONAL CUSTOM

About us

EXHIBITION

Specification

|

Product name

|

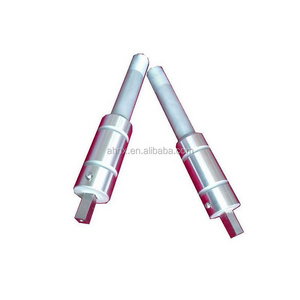

precision non-standard punch and die deep draw hole steel forming hex profile square hole tungsten carbide cold metal punch die

|

|

Brand name

|

JUNYU

|

|

Tolerance

|

+-0.002mm

|

|

Material

|

Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect

|

|

Standard

|

Davton.Lane.DIN.ISO.MISUMIEDM.FIBROMOELLERHASCO.ect

|

|

Surface work

|

TiCNTiN,Aitain,TicrnnitridingBlack oxygenedBlack coating etc available

|

|

Polishness

|

ClosetoRa0.2 Hardness Depends on material(HRC60~94)

|

|

Hardness

|

Depends on material(HRC60~94)

|

|

The time of delivery

|

3-5 Working days,depends on the quantity the order.Express by DHL,UPS,FEDEX,TNT or Ocean Shipping etc.

|

Product Description

WHY CHOOSE US

Production and Packaging

FAQ

1. Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in Dongguan, China.

2.. How soon can I get samples?

Depending on your specific project, it usually takes 7 to 15 days.

3. How do you control the quality?

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

4. Is it possible to know how are my products going on without visiting your company?

We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

5. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Product Description

Hot Searches