- Product Details

- {{item.text}}

Quick Details

-

Power:

-

100kw

-

Weight:

-

2800 KG

-

Dimension(L*W*H):

-

5620*1900*3140mm

-

Product name:

-

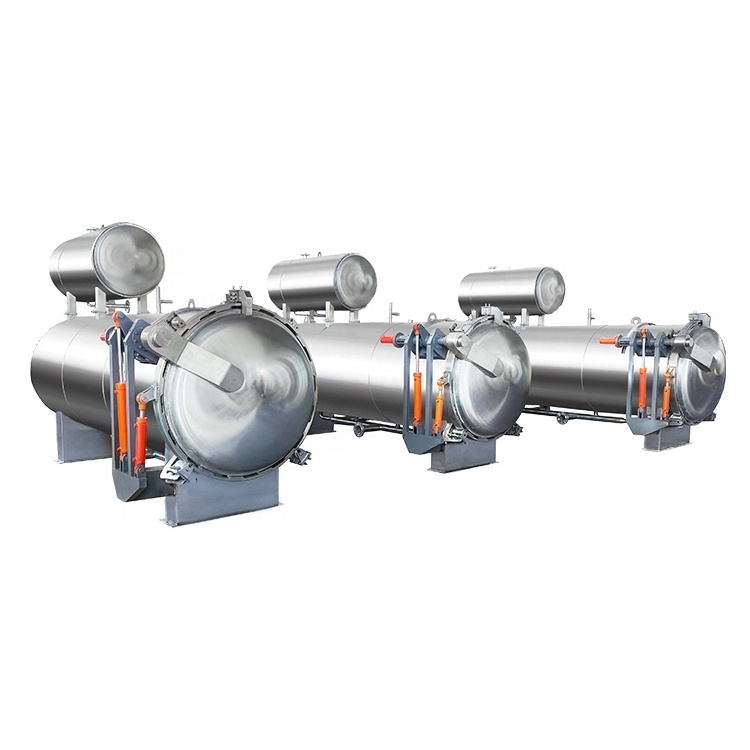

Good Quality Autoclave for Mushroom Cultivation

-

Material:

-

SUS304

-

Function:

-

High temperature sterilization

-

Advantage:

-

High Productivity

-

Capacity:

-

1100kg/times

-

Model:

-

HSSJ-1200

-

Size:

-

5620*1900*3140mm

-

Brand:

-

Hengshi

-

MOQ:

-

1 Set

-

Package:

-

Wooden Case

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hengshi

-

Voltage:

-

220V/380V

-

Power:

-

100kw

-

Weight:

-

2800 KG

-

Dimension(L*W*H):

-

5620*1900*3140mm

-

Product name:

-

Good Quality Autoclave for Mushroom Cultivation

-

Material:

-

SUS304

-

Function:

-

High temperature sterilization

-

Advantage:

-

High Productivity

-

Capacity:

-

1100kg/times

-

Model:

-

HSSJ-1200

-

Size:

-

5620*1900*3140mm

-

Brand:

-

Hengshi

-

MOQ:

-

1 Set

-

Package:

-

Wooden Case

Products Description

Spray sterilization pot is to inject a small amount of process water to reach the predetermined position (can't soak the product) through a high efficiency circulation pump - strainer - high efficiency heat exchanger to inject water into the spray pipe, and then through the spray nozzle to spray hot water atomization to the surface of food, the heat distribution in the pot is uniform,no sterilization dead Angle.The water is heated and cooled by heat exchanger, and the heating and cooling speed are fast, which can sterilize the products efficiently, comprehensively and stably.

Details Images

Equipment features:

1. Indirect heating and indirect cooling, the cooling water is not in contact with the process water, which avoids secondary

contamination of food and does not need to be used for chemical preparation of water treatment.High temperature short time sterilization.

2. Reduce steam consumption. The sterilizing water after steam atomization is directly mixed in the sterilizing kettle to improve the heating and cooling speed.

3, a small amount of process water quickly cycle, quickly reach the predetermined sterilization temperature.

4, low noise, to create a quiet and comfortable working environment.

5. The kettle is equipped with four movable temperature sensing probes, which can monitor the F value of the food center and the heat distribution in the kettle at any time, so as to know the heat penetration at any time.

6, perfect pressure control, the pressure in the whole production process is constantly adjusted to adapt to the changes in the internal pressure of the product packaging, so that the deformation of the product packaging to reach the minimum, especially suitable for products containing gas packaging.

7, the process water preheating system can ensure that the heat preservation, heat filled products get a continuous heating process.

8. The water used for sterilization shall be softened to avoid the problem of water quality in the process, which will cause no dirt in the outer package.

1. Indirect heating and indirect cooling, the cooling water is not in contact with the process water, which avoids secondary

contamination of food and does not need to be used for chemical preparation of water treatment.High temperature short time sterilization.

2. Reduce steam consumption. The sterilizing water after steam atomization is directly mixed in the sterilizing kettle to improve the heating and cooling speed.

3, a small amount of process water quickly cycle, quickly reach the predetermined sterilization temperature.

4, low noise, to create a quiet and comfortable working environment.

5. The kettle is equipped with four movable temperature sensing probes, which can monitor the F value of the food center and the heat distribution in the kettle at any time, so as to know the heat penetration at any time.

6, perfect pressure control, the pressure in the whole production process is constantly adjusted to adapt to the changes in the internal pressure of the product packaging, so that the deformation of the product packaging to reach the minimum, especially suitable for products containing gas packaging.

7, the process water preheating system can ensure that the heat preservation, heat filled products get a continuous heating process.

8. The water used for sterilization shall be softened to avoid the problem of water quality in the process, which will cause no dirt in the outer package.

A variety of spray and heat transfer methods are available to meet the requirements of different products.

Product Paramenters

|

Model

|

volume

|

power

|

voltage

|

Maximum working pressure

|

|

1000

|

2.2m³

|

4kw

|

380V/220V

|

0.4Mpa

|

|

1200

|

4.58m³

|

5.5kw

|

380V/220V

|

0.4Mpa

|

|

1300

|

5.3m³

|

5.5kw

|

380V/220V

|

0.4Mpa

|

|

1500

|

10.05m³

|

15kw

|

380V/220V

|

0.4Mpa

|

Applicable Scope:

Spray sterilization pot is suitable for all kinds of high temperature resistant packaging materials:

1. Plastic containers: PP bottles, HDPE bottles.

2. Soft bag packaging: aluminum foil bag, transparent bag, vacuum bag, high temperature cooking bag, etc.

3. Tin cans: aluminum cans and glass bottle products

Spray sterilization pot is suitable for all kinds of high temperature resistant packaging materials:

1. Plastic containers: PP bottles, HDPE bottles.

2. Soft bag packaging: aluminum foil bag, transparent bag, vacuum bag, high temperature cooking bag, etc.

3. Tin cans: aluminum cans and glass bottle products

Hot Searches