Support FASTCAM, ARTCAM, Type3 software

CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc.

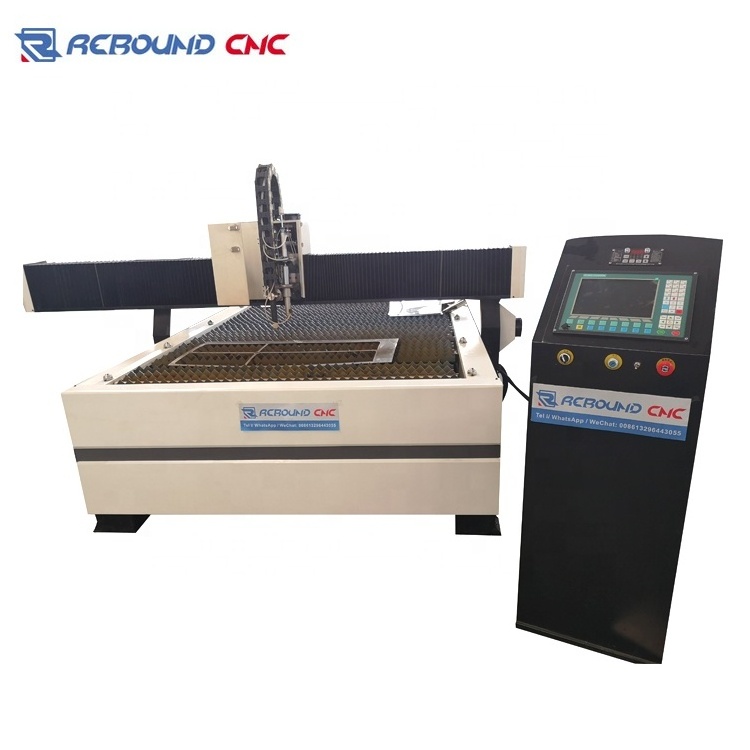

- Product Details

- {{item.text}}

Quick Details

-

Machine body:

-

Steel Welded Structure

-

Transmission:

-

Rack Pinion

-

Cutting thickness:

-

0-30mm (Plasma cutting) 10-200mm(Flame cutting)

-

Plasma power:

-

LGK

-

Control system:

-

Starfire or Fangling + THC Controller

-

Drive motor:

-

Stepper or Servo Motor Driver

-

Machine table:

-

Blade or Sawtooth

-

Software:

-

Original FastCAM Software

Quick Details

-

Place of Origin:

-

China

-

Cutting mode:

-

Plasma Cutting (Flame cutting optional)

-

Product name:

-

Table cnc plasma cutter

-

Machine body:

-

Steel Welded Structure

-

Transmission:

-

Rack Pinion

-

Cutting thickness:

-

0-30mm (Plasma cutting) 10-200mm(Flame cutting)

-

Plasma power:

-

LGK

-

Control system:

-

Starfire or Fangling + THC Controller

-

Drive motor:

-

Stepper or Servo Motor Driver

-

Machine table:

-

Blade or Sawtooth

-

Software:

-

Original FastCAM Software

Product Description

|

Model

|

RB-1530

|

|

Working Voltage

|

AC 220V/380V, 50HZ

|

|

Working Size

|

1500mm*3000mm

1300mm*2500mm

|

|

Max Cutting Speed

|

12000mm/min

|

|

Cutting Thickness

|

0-30 mm, according to different plasma power

|

|

Plasma power

|

LGK 63-200A

Hypertherm 45-200A

|

|

Air pressure

|

0.4Mpa

|

|

Packaging size:

|

3.7m*2.3m*1.6m

|

|

Weight

|

1200KG

|

Feature

1. The machine steel structure is processed by the precision machine tool, solid and reliable, durable.

2. STARFIRE control system, the file incision and export automatic correction , real-time tracking detection of plasma power in the process of cutting current.

3. Magnet anti-collision design, simple and effective. When the cutting torch collides with the steel plate, the machine stops working automatically.

4. The machine adopts China HUAYUAN power or USA Hypertherm. It is easy to learn and operate with fast cutting speed and high cutting quality.

5. The machine also has feature that automatic arc voltage torch height control, it can adjust cutting distance automatically.

Application

Applies in cars, motorcycles, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery,steel structure, hipbuilding and other industries.

Samples

Detailed Images

Control system: STARFIRE

Torch Height Controller

Adjust the torch cutting distance automatically with high precision when the bent metal cutting.

Plasma machine beam.

Professional industrial aluminum material

Good steel property, light weight and small inertia. Improve cutting speed and life.

The beam can be disassembled and assembled, which facilitates the field transfer and packing and transportation, and ensures that the perpendicularity of the beam is unchanged.

Plasma torch base.

The plasma torch works up and down through ball screws and square rail sliders with fast speed and good accuracy.

Driving System

Servo or Step driver and motor

Y-axis adopts synchronous double-motor double-drive which drives smoothly and runs with high precision

Linear guide rail

Three axes adopt Taiwan HIWIN high precision square orbit

Plasma machine

table

Saw

table(Optional

Blade

tooth table)

Related Products

Packing&Shipping

After Sales Service

1. We will supply the whole day on-line service to foreign customers. According to foreign customer's requirement, we will arrange technicians go abroad to install or maintain the machine.

2. Within warranty period and the machine parts damage under normal using condition, we will offer new ones for replacement.

3. After the expiry of warranty, we can renewal of the contract, which can enjoy the same service that during the warranty period.

4.Our company will research the staffs service attitude aperiodically to improve the service satisfaction.

2. Within warranty period and the machine parts damage under normal using condition, we will offer new ones for replacement.

3. After the expiry of warranty, we can renewal of the contract, which can enjoy the same service that during the warranty period.

4.Our company will research the staffs service attitude aperiodically to improve the service satisfaction.

Customer approval

Company Introduction

Jinan Rebound CNC Machine Co.,Ltd. located in Jinan City, Shandong Province, is China manufacturer of CNC cutting solutions for wood, iron, steel , leather, fabric, carbon by plasma cutting machines, laser cutting machines, cnc router machine, oscillating knife cutting machines. By years of development, CNC cutting machines have been sold all over the world.

In recent years, REBOUDN CNC, in active response to the macro-situation of economic restructuring and transition, has worked out the strategy of “Innovation” and “Brand”. Science and Technology are the driving force of enterprises. Rebound Machine and local famous universities have built up an R and D base and have been carrying out a key pilot project at the provincial level. From Made in China to Created by China; Produce Better and Up-to-date Products" is the aspiration of REBOUND. “We Have Always been Working Hard to Revitalize our National Industry and Realize China Dream” reflects our strong insistence on national revival and prosperity.

Superiority originates from professionalism, Professionalism originates from unremitting pursuit. Pursuit originates from the spirit of dedication to national industry. REBOUND CNC has been trying to set up an industrial brand, turn out high-quality machine and take part in international competition. We would like to create a brilliant cause hand in hand with you!

FAQ

1. Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2. Q: I am not sure if this machine suitable for my work?

A: Don't worry, just tell me your working materials, max working area and cutting thickness, then I will recommend you the most suitable machine for you.

3. Q:What other things also need after we bought your machines?

A:With plasma cutting: need plasma power source and air compressor. You can match plasma power supply by yourself, or buy together with the cutter from us, it's optional. If you buy from us, we will connect the wires of plasma power source and CNC cutting machine together, then more conveniently to use.

4. Q:How can i do if the machine goes wrong?

A:If confronted with such problems, online service is offered, you could contact our sales. Also, we offer engineer delivery service .Please contact us ASAP and don’t try fix the machine by yourself or someone else. We will response within 12 hours as quick as we can to solve it for you.

Contact Us

Hot Searches