- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Place of Origin:

-

China

-

Brand Name:

-

UTECS

-

Dimension(L*W*H):

-

3000*1450*1650mm

-

Weight:

-

1000 KG, 1000kgs

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

automatic laminator:

-

automatic laminator

-

Max Paper Size:

-

760*540mm

-

Min Paper Size:

-

240*270mm

-

Laminating Speed:

-

0-35m/min

-

Gross Power:

-

17kw

-

Dimensions:

-

3000*1450*1650mm

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Metal, Paper, Plastic

-

Driven Type:

-

Hydraulic

-

Voltage:

-

380

-

Place of Origin:

-

China

-

Brand Name:

-

UTECS

-

Dimension(L*W*H):

-

3000*1450*1650mm

-

Weight:

-

1000 KG, 1000kgs

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

automatic laminator:

-

automatic laminator

-

Max Paper Size:

-

760*540mm

-

Min Paper Size:

-

240*270mm

-

Laminating Speed:

-

0-35m/min

-

Gross Power:

-

17kw

-

Dimensions:

-

3000*1450*1650mm

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Ordinary Product

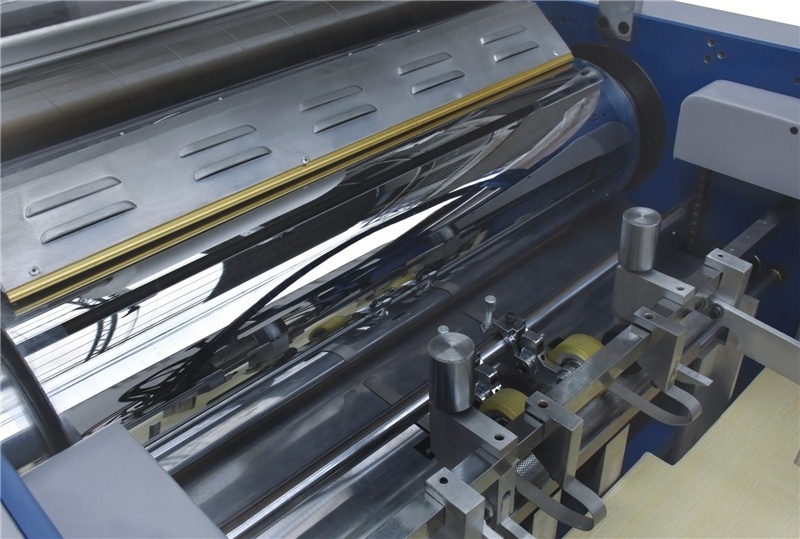

SAFM540 Glueless Preglued Digital Automatic Thermal Laminator, Auto Hot Bopp Film Laminating Machine

Video demonstration only for reference

Video : https://www.youtube.com/watch?v=LOGahIhjbmM

Features:

1. Automatic paper feeder adopts oil-free vacuum pump to feed paper automatically.

2. Automatic paper feeding system is equipped with no paper protector and paper break protector, which are controlled by photoelectric and mechanical systems. When no paper or paper break occurs, the machine will stop automatically for self-protection.

3. Man-machine interface system: color touch screen simplifies the machine operation. On the touch screen, as long as the operator inputs paper size, overlap length and working speed etc., the machine can realize completely automated operation. And on touch screen, working status of the machine can be checked at any time.

4. High precision of chrome plated heating roller is equipped with built-in oil heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.

5. Pneumatic pressuring system provides automatically stable pressure to guarantee good laminating quality. And the pressure can also be adjusted upon requests.

6. Air expansion shaft releases film roll, and positions film roll more accurately, and also makes the loading and unloading of film roll more convenient.

7. The combination of air expansion shaft and braking device can adjust film release tension and speed.

8. Film cutter cuts film width to make it meet paper size.

9. Serrated perforating wheel perforates film edge for the automatic cut of laminated paper.

10. Anti-curvature device: when going though the anti-curvature device, the laminated paper shall be leveled at once and won’t curve again after cut.

11. Pneumatic cutting system realizes automatic paper cut.

12. After cut, the laminated paper will be sent automatically to vibrating receiving table and be put into order.

Parameters:

|

Model No. |

SAFM-540 |

|

Max Paper Size |

760*540mm |

|

Min Paper Size |

240*270mm |

|

Laminating Speed |

0-35m/min |

|

Paper Thickness |

157-400gsm |

|

Gross Power |

17kw |

|

OverallDimensions |

3000*1450*1650mm |

|

Weight |

1000kgs |

Automatic Feeder

Electromagneticc Heat System

Perforating and Cutting Knife

Human-Computer Interface for Easy Setting

Post Control Panel for Easy Operation

Corrugated Delivery System for Easy Paper Collection

1.Q: What information should i let you know if i want to get a quotation?

A: What is your Max and Min product size in mm?

B: What is your paper thickness in GSM?

C: Some photos of your finished products

2.Q: Are you a manufacturer?

A: Yes we have been manufacturing such machines over 20 years and also we are a professional exporter.

3.Q: What about the payment term?

A: Mostly 30%T/T in advanced, 60% when machine is finished after inspection and last 10% against copy of shipping documents..

4.Q: What is the warranty?

A: Two year warranty after sales (During the warranty period, we respond for free parts dispachment and the buyer is only required to cover the courier express once the machine has any problems. However we do not respond for the consumables and parts broken by mistakingly operation)

5.Q: What is your aftersale service ?

A: Any questions will be responded within 24 hours by email, skype, phone call or Whatsapp/Wechat (+86-18258286679) . In addtion, we have professional engineer available for overseas service. .

6.Q:What is the delivery time?

A: Mostly it takes 10 to 30 workdays after receiving the deposit and confirming the drawing or samples as required.

Wooden Case Loading and Transport

YOU ARE WELCOME TO CONTACT US ANYTIME AVAILABLE.

Mobile/Whatsapp/Wechat: +86-18258286679

Email: utecs @ utecsinter.com, utecsinter@ gmail.com, danielsuer@ live.com

Skype: danielsuer

Web: www.utecsinter.com