Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YTTEST

-

Model Number:

-

YTTEST-SL132

-

Type:

-

Mirror Dedicated

-

Product name:

-

Silicone Sealant Glue

-

Color:

-

White

-

Packing:

-

24 Pcs/carton

-

MOQ:

-

96 Pcs

-

Volume:

-

300 Ml

-

Shelf life:

-

12 Months

-

Feature:

-

Bonding Strength

-

Advantage:

-

Environment Friendly

-

Service temperature:

-

-40℃~150℃

-

Use:

-

Mirror

Quick Details

-

CAS No.:

-

7085-85-0

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YTTEST

-

Model Number:

-

YTTEST-SL132

-

Type:

-

Mirror Dedicated

-

Product name:

-

Silicone Sealant Glue

-

Color:

-

White

-

Packing:

-

24 Pcs/carton

-

MOQ:

-

96 Pcs

-

Volume:

-

300 Ml

-

Shelf life:

-

12 Months

-

Feature:

-

Bonding Strength

-

Advantage:

-

Environment Friendly

-

Service temperature:

-

-40℃~150℃

-

Use:

-

Mirror

Products Description

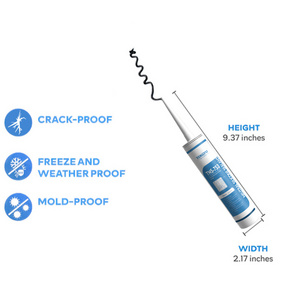

Professional anti-mold silicone sealant waterproof for mirror glue

Transparent silicone adhesive for glass is a one-part, acetoxy silicone sealant for many applications.

It cures at room temperature in the presence of atmospheric moisture to give a permanent flexible silicone rubber.

|

Product Name

|

Silicone Sealant

|

|

Specification

|

24pcs/ctn 300ml/pcs

|

|

Color

|

Transparent

|

|

Scope of application

|

Mirror Dedicated

|

Instructions

Clean the bonding surface to ensure that there is no oil and dust.

Cut the nozzle, poke the aluminum film with a glue nozzle, put on the glue nozzle and squeeze it out with a glue gun;

Glue dots, strips, z-shapes, etc. on the back of the bonding material. The lighter materials can be glued and compacted. After the heavier materials are glued and pressed, they can be gently pulled off, and the wire is drawn 3-5 times. , And then compact both sides to be positioned.

After bonding, the position can still be moved and adjusted within a short time, and the strength can be reached within 24 hours, and the best strength can be reached within 72 hours.

Certifications

Works Show

Packaging & Delivery

Hot Searches